By Li Wei, Senior SMT Process Engineer at Suzhou JEENOCE Electronic Co., Ltd. – With over 15 years in electronic manufacturing, specializing in SMT integration and reflow oven optimization.

JEENOCE focuses on technology-oriented development and sales of digital SMT integration and non-standard automation products, serving high-end EMS manufacturers worldwide.

Reflow soldering is a pivotal surface-mount technology (SMT) process where solder paste is applied to PCB pads, components are placed, and the assembly is heated in a controlled furnace to melt the solder, forming reliable electrical connections. Key terms like solder paste, temperature profile, and convection heating ensure precision in modern electronics assembly.Imagine it like baking cookies in an oven: the "dough" (solder paste) spreads evenly as heat rises, bonding chips to the board without direct flame—simple, efficient, and essential for high-volume production.

JEENOCE's digitalized SMT solutions combine high-efficiency ovens with MES/ERP integration, helping manufacturers reduce defects by up to 20% and improve yield rates across global EMS and OEM lines.

At its core, reflow soldering relies on flux activation in the solder paste, which cleans surfaces for wetting, followed by thermal conduction or convection to follow a precise temperature curve. This melts the alloy (typically Sn63/Pb37 or lead-free SAC305) above its melting point (~217°C) while avoiding component damage.

Standard IPC Profile Guidelines

Phase | Ramp Rate (°C/s) | Peak Temp (°C) | Time Above Liquidus (s) | Cooling Rate (°C/s) |

Preheat | 1-3 | 150-180 | N/A | N/A |

Soak/Activation | 0.5-1 | 180-220 | 60-120 | N/A |

Reflow | 1-3 | 235-260 (lead-free) | 40-90 | -2 to -4 |

Cooling | N/A | Room temp | N/A | Natural |

JEENOCE integrates proprietary software platforms with MES/QM/ERP systems, enabling real-time monitoring of soldering profiles, component-level traceability, and visual Kanban dashboards.

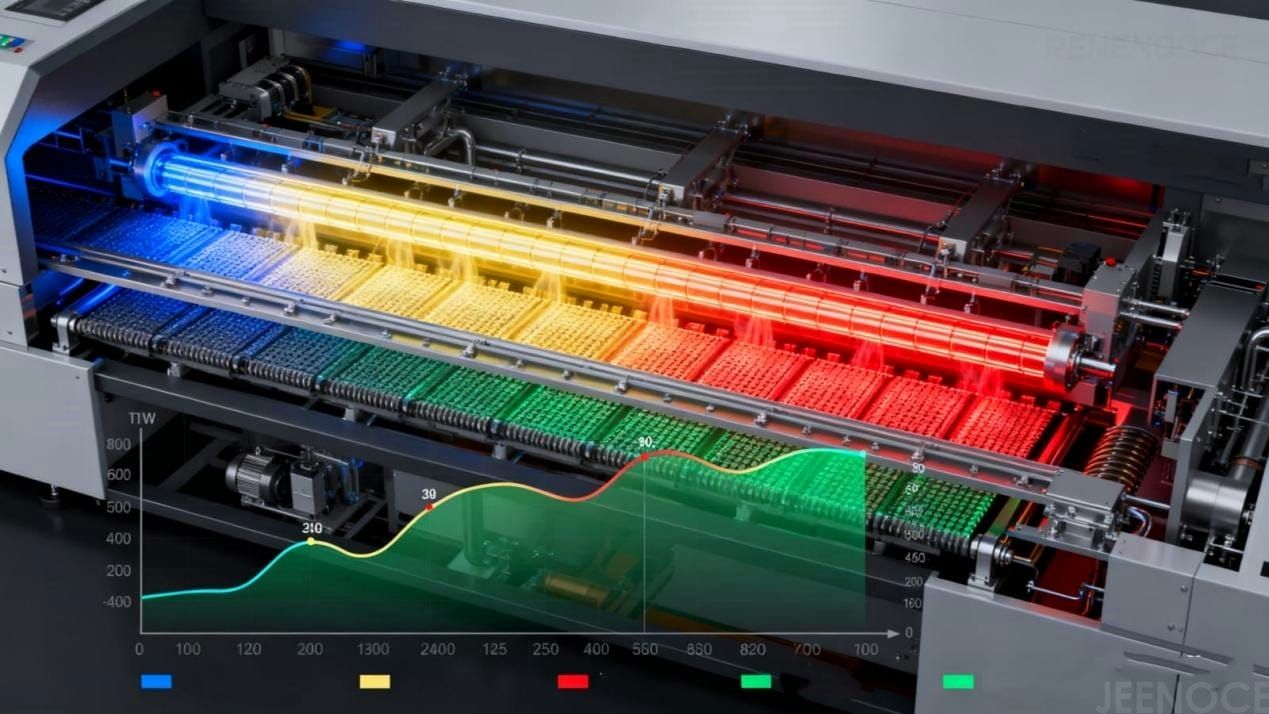

The process unfolds in a multi-zone furnace:

1. Preheat Zone: Gradual heating (100-150°C) evaporates solvents from solder paste, minimizing thermal shock to components.

2. Soak/Activation Zone: Flux activates (150-200°C), preparing pads for wetting without rapid spikes.

3. Reflow Zone: Solder melts (220-260°C), forming intermetallic bonds as components self-align.

4. Cooling Zone: Controlled cooldown solidifies joints, preventing stress cracks.

Case Example: JEENOCE assisted a leading automotive electronics client in reducing voiding rates by 15% by optimizing soak-zone timing, thus enhancing ECU reliability.

JEENOCE offers full-spectrum reflow solutions tailored to scale and precision:

Convection Reflow: Hot air circulates for uniform heating—ideal for high-volume SMT.

Infrared Reflow: IR lamps for targeted heating, suited for dense boards.

Vapor Phase Reflow: Condensing vapor ensures even temps, perfect for prototypes.

Method | Equipment Cost | Efficiency (Boards/Hour) | Best For |

Convection | Medium ($50K-$200K) | High (500-2000) | Consumer electronics, JEENOCE's flagship for phone assembly lines |

Infrared | Low ($20K-$100K) | Medium (200-800) | Small batches, quick setups in R&D |

Vapor Phase | High ($100K-$300K) | Low (50-300) | High-reliability medical devices, with JEENOCE's nitrogen-compatible upgrades |

JEENOCE specializes in SMT line integration, providing not only reflow ovens but also non-standard automation upgrades, test fixtures, and post-assembly solutions for complete production lines.

Aspect | Reflow Soldering | Wave Soldering |

Components | SMD (fine-pitch) | THT (through-hole) |

Cost per Board | Lower for mass production | Higher for low-mix |

Throughput | 1000+ boards/hr | 200–500 boards/hr |

Applications | Smartphones, ECUs, sensors | Power modules, connectors |

Consumer Electronics: Phones, laptops, smart devices.

Automotive: ADAS, ECUs, EV modules.

Medical: Precision devices, implantable electronics.

Telecom & Data Centers: High-reliability PCBAs.

Market insight: The global SMT market reached $6.21 billion in 2025, projected to grow at a CAGR of 9.4% through 2030. JEENOCE powers production lines in over 50 countries, from Continental's EV sensors to Osram's lighting modules, with a global network of 34 after-sales partners.

Cause: uneven heating.

Solution: Controlled ramp <2°C/s.

Cause: paste spattering.

Solution: Viscosity optimization + JEENOCE defect monitoring tools.

Cause: gas entrapment.

Solution: Extended soak, JEENOCE MES alerts.

JEENOCE offers a troubleshooting toolkit with real-time defect detection and MES-based optimization, reducing defect rates by up to 18% in client factories.

Key selection: ±1°C temp accuracy, nitrogen atmosphere for oxidation-free welds, and conveyor speed matching your line (e.g., 1-5m/min). JEENOCE ovens support air/nitrogen hybrids for cost savings, integrated with our PLM, MES, and ERP systems for efficient, high-quality production.

Standards: Follow IPC-7530 for profiles, IPC-A-610 for acceptability, and SMTA for best practices—our systems auto-comply, embodying our corporate culture of the pursuit of excellence and pragmatic innovation.

PS:Contact our over 20 after-sales engineers for custom configurations—with a response time of less than 2 hours via our 24/7 hotline.

Reflow soldering drives the efficiency, quality, and scalability of global electronics manufacturing.JEENOCE delivers more than equipment—we deliver turn-key SMT solutions, combining digital factory systems, high-end automation, and global service networks (34 after-sales centers worldwide, response time <2 hrs).

Ready to reflow smarter? [Schedule a Free Consultation]

Message