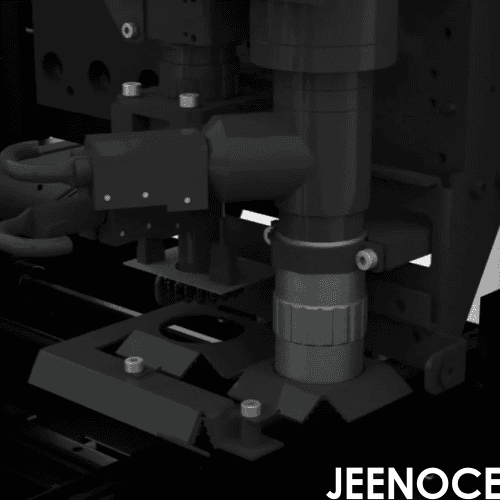

Experience the future of bonding process inspection with the Jeenoce BondInspect AOI System — a high-precision automated optical inspection (AOI) solution designed specifically for wire bonding and die bonding applications in semiconductor packaging and PCB assembly. Our system combines cutting-edge 3D optical technologies and AI-powered defect detection to deliver unmatched accuracy in bonding process inspection, helping manufacturers catch defects early and improve yield.

Quick Specs at a Glance:

3D Wire & Die Profiling: Advanced 3D optical inspection for detailed bonding analysis

High-Speed Line-Scan Technology: Rapid, inline inspection to keep up with production lines

AI-Powered Defect Classification: Smart detection of ball bonds, wedge bonds, loops, nd wire defects

Modular Design: Flexible integration for SMT, flip-chip, and semiconductor packaging lines

Ready to elevate your bonding quality control?

Keep your bonding processes secure and defect-free with Jeenoce BondInspect — your reliable partner in automated wire bond defect detection and high-precision bonding process scanning.

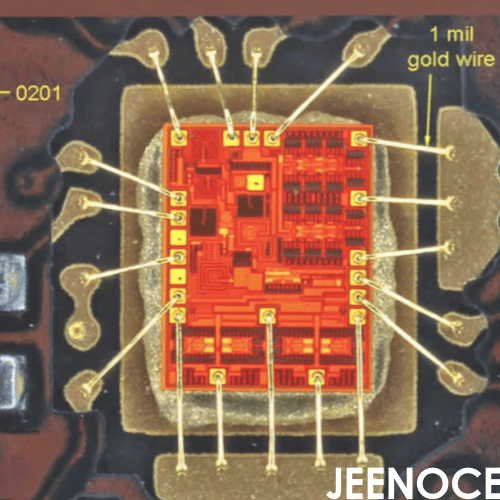

Bonding processes, especially in semiconductor packaging and PCB assembly, are critical but prone to defects like wire breaks, ball bond issues, and improper wedge or loop profiles. These defects can cause electrical failures and reduce product reliability. Manual visual inspection often struggles to catch subtle or hidden flaws, leading to inconsistent results and higher chances of missed defects.

Industry data shows that bonding-related defects cause significant yield loss—sometimes up to 20%—which means costly rework, scrap, and delays. As production volumes grow, relying on manual inspection isn’t sustainable. The limits of human inspection create a real bottleneck in maintaining quality and efficiency on the line. That’s why automated, high-precision AOI equipment tailored for bonding processes is essential for advanced semiconductor industries looking to boost yield and reduce waste.

Why is AOI equipment more efficient than manual labor?

The most important core of the AOI equipment is actually the image system and algorithm system two parts.

The high-resolution megapixel camera, combined with an ultra-high frame rate and multi-angle coaxial ring light source, captures clear images even in high-speed production environments.

Combined with a powerful algorithm system, such as the U.S.-patented system used in our AOI equipment, it can continuously identify defects like tiny beads and soldering issues in SMT processes, which are difficult for the human eye to detect.

Additionally, it allows for tracing back to the source of the problem through recorded data.

Detection method | Detection Target | Testing process | Working Principle | difference and similarity |

Automated Optical Inspection | Inspection of product surface appearance defects

| Before and after SMD, before and after soldering

| Optical Imaging Comparison

| Interchangeable with SPI and complementary to Xray detection |

In-Circuit Test | Electrical function testing

| Finished product testing

| Probe Electrical Inspection

| Mainly functional tests, no common ground |

Solder Paste Inspection | Solder Paste Printing Effect Inspection

| After solder paste printing only

| Optical scanning, 3D measurement

| Interchangeable with AOI, but only in the solder paste printing process |

Automated Visual Inspection | For surface inspection (not only for electronics)

| Both. Mainly cosmetic inspections

| High Precision Image Processing

| Not exactly a specialized counterpart to the electronics industry |

X-ray inspection

| Internal Structure Inspection

| Post-soldering and finished product testing

| X-ray imaging

| Mainly different detection principles,AOI, SPI,AVI are considered optical methods, Xray inspection is mainly dependent on the principle of X-ray penetration |

Jeenoce BondInspect AOI is a high-precision automated optical inspection system designed specifically for bonding process inspection. It uses advanced 3D optical inspection tech to detect defects in wire bonding, die bonding, ball bonds, wedge and loop profiles, and other critical interconnect points.

Core Functionality

Automated wire bond defect detection — scans and identifies issues like lifted wires, missing or weak bonds.

3D wire and die profiling — measures bond shapes and solder ball positions in three dimensions for accurate quality control.

High-speed line-scan technology — inspects quickly without sacrificing detail, perfect for fast-paced semiconductor packaging and SMT PCB assembly lines.

AI-Powered Defect Classification — smart algorithms classify defects with high accuracy, reducing false alarms and manual rechecks.

Unique Features

| Feature | Benefit |

|---|---|

| 3D Optical Inspection | Detects tiny bond defects missed by traditional AOI |

| AI Defect Classification | Speeds up inspections and improves accuracy |

| Modular System Integration | Easy to add to existing SMT or packaging lines |

| User-Friendly Interface | Simplifies operation, minimal training needed |

| Inline AOI for Flip-Chip & Wire Bonding | Supports multiple bonding types in one system |

Inspection range of AOI equipment

Types of products tested | Multi-Chip Modules, Hybrid ICs, Flip Chips, Ball Grid Array Packages, Micro Ball Grid Array Packages, MEMS, Waffle Disks, etc. |

Detectable defect

Gold (aluminum) wire defects | Missing, damaged, soldered, de-padded, warped/lifted |

Die defects | Missing,wrong parts, polarity, peeling, cracking, contamination |

Component defects | Location, Missing, Wrong Piece, Polarity, Tilt, Tombstone |

Epoxy defects | Contamination, under-volume, over-volume, bridging |

Solder defects | Contamination, under-volume, over-volume, bridging |

Target Applications

Semiconductor packaging lines — Ensures post-wire bond quality control to reduce yield loss.

SMT PCB assembly — Quality check for interconnects, ball bonds, and solder joints.

Flip-chip bonding — In-line inspection that keeps up with high-volume production.

Advanced electronics manufacturing — Where high precision and reliability are critical.

Jeenoce BondInspect AOI fits right into modern manufacturing workflows, powering smarter, faster, and more reliable bonding process inspection.

Jeenoce BondInspect AOI stands out with the latest tech to tackle bonding process challenges. Here’s what makes it a game-changer:

3D Wire and Die Profiling

Measures wire bonds and die height in 3D

Detects ball bond, wedge, and loop shape defects

Provides precise, real-time profiling for both wire bonding AOI machine and die bonding inspection

High-Speed Line-Scan Technology

Captures detailed images at line rates without slowing production

Ideal for inline AOI in flip-chip bonding and SMT PCB assembly

Ensures every detail is checked with no bottleneck

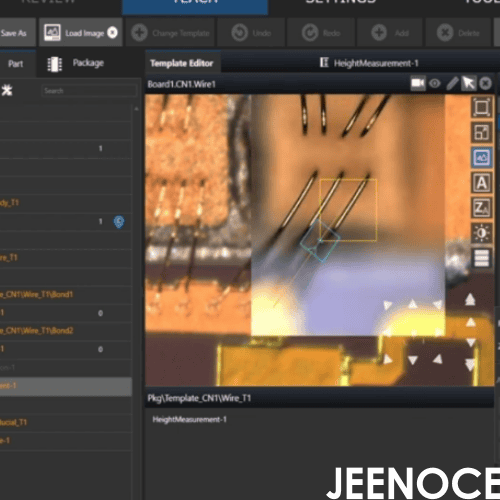

AI-Powered Defect Classification

Uses smart algorithms to identify common defects automatically

Cuts false calls, improves accuracy in wire bond defect detection

Supports post-wire bond quality control equipment and ball bond inspection tools

Modular Integration and User Interface

Easily integrates into existing semiconductor packaging AOI systems

User-friendly touchscreen with customizable workflows

Scalable setup for different production line sizes

Feature Comparison Table

| Feature | Jeenoce BondInspect AOI | Standard AOI Systems | Manual Inspection |

|---|---|---|---|

| 3D Wire and Die Profiling | ✔ | ✘ | ✘ |

| High-Speed Line-Scan | ✔ | Limited | ✘ |

| AI Defect Classification | ✔ | Basic or none | ✘ |

| Modular Integration | ✔ | Some | ✘ |

| Real-time Yield Monitoring | ✔ | ✘ | ✘ |

| Automated Feedback Loop | ✔ | ✘ | ✘ |

This mix of advanced optical inspection equipment and smart software makes Jeenoce BondInspect a reliable choice for accurate bonding process inspection and automated quality inspection on the shop floor.

Optical and Mechanical Specs

| Feature | Details |

|---|---|

| Camera Type | 8.2 x 6.8 mm (0.32 x 0.27 in) (1x) |

| Optical Resolution | 3.4 micron (1x) |

| Illumination | Proprietary Fusion Lighting™ Multi-Angle LEDs |

| Imaging | 5-megapixel color camera (2448 x 2048) |

| Optical Device | Proprietary high-resolution, low-distortion coaxial illumination with optional Focus Variation Measurement (FVM) metrology module |

| AFVM - Metering Module | Focus Change Measurement Sensor |

| 3D Profiling | Wire and die shape scanning |

| System Size | 110 x 128x 143 cm (W x D x H) Height excludes signal-light pole and levelling feet |

Conveyor specifications

| Feature | Details |

|---|---|

| Maximum Substrate Size | 440 x 450 mm (17.3 x 17.7 inches) |

| Minimum Substrate Size | 50 x 50 mm (2 x 2 inches) |

| Substrate Edge Clearance | 3 mm (0.12 inches) |

| Substrate thickness | 0.1 to 7.0 mm |

| Maximum Substrate Weight | 3.0 kg (6.6 lbs) |

| Clearance height | Top: 19 mm (0.75 in.) (50 mm travel); Bottom: 50 mm (2 in.) |

| Conveyor height | 930 - 980 mm (36.6 - 38.6 inches) (configurable to 880 - 950 mm) |

| Conveyor length | 1100 mm (43.3 inches) |

| Conveyor direction | Left to right (configurable to right to left; please contact the JEENOCE technical team for details) |

Software Capabilities

AI-Powered Defect Detection: Automated wire bond defect classification and real-time alerts

User Interface: Intuitive touchscreen with customizable dashboards

Data Management: Exportable reports compatible with major MES and SPC systems

Integration: Supports inline AOI workflows including flip-chip bonding and SMT PCB assembly

Environmental Compliance

RoHS and REACH compliant components

Low power consumption design to minimize energy usage

Quiet operation with noise levels under 60 dB

Performance Metrics

| Metric | Value |

|---|---|

| Detection Accuracy | >99.5% |

| False Reject Rate | <0.1% |

| Equipment Uptime | 98% average |

| Calibration Interval | 6 months recommended |

| Maintenance | Easy-access parts for quick servicing |

Jeenoce BondInspect’s technical specs ensure reliable, high-precision bonding process inspection that fits right into your production line without disruption.

Jeenoce BondInspect AOI brings real advantages that boost your production efficiency and cut costs.

Yield Improvement and Cost Savings

Early Defect Detection: Catch wire bonding and die bonding flaws instantly, avoiding costly rework.

Reduced Scrap Rates: Precise AOI with 3D optical inspection lowers material waste.

Consistent Quality: Automated wire bond defect detection ensures fewer escapes, less downtime.

Scalability and Compliance

Modular System: Grows with your production needs—from SMT PCB assembly to semiconductor packaging AOI.

Industry Standards: Meets key environmental regulations and traceability requirements.

ROI Visual Breakdown

| Benefit | Impact | Timeline |

|---|---|---|

| Reduced Scrap & Rework | Up to 30% cost savings | Within 3 months |

| Increased Yield | Up to 15% production gain | Immediate |

| Faster Line Throughput | 20% faster inspections | After setup tuning |

| Lower Labor Costs | Automation reduces manual checks | Ongoing |

For manufacturers in Singapore, Japan, Korea, and Taiwan, the BondInspect system delivers measurable returns fast—helping your line stay competitive with high-precision bonding process scanners designed for real-world demands.

Our Jeenoce BondInspect AOI system has proven its value across multiple industries, delivering reliable results and clear ROI.

Semiconductor Packaging Line Success

In a leading U.S. semiconductor plant, our AOI equipment for bonding processes helped reduce wire bond defects by 40%. The 3D optical inspection for die bonding caught issues early that manual checks missed, improving overall yield and cutting rework costs. Inline AOI for flip-chip bonding streamlined the packaging process, allowing fast, accurate defect detection without slowing production.

SMT PCB Assembly Deployment

For SMT assembly lines, the BondInspect system excels at automated wire bond defect detection and ball bond inspection. One customer reported a 30% drop in failed boards after switching to our AOI solution for PCB inspection, saving time while boosting quality control. The wedge and loop profiling AOI feature keeps interconnects tight and consistent, ideal for high-volume production.

Application Gallery

Post-wire bond quality control equipment: Ensures every bond meets specs before continuing.

High-precision bonding process scanner: Captures detailed images that reveal subtle issues.

Smart AOI systems for PCB defect detection: Finds defects invisible to the naked eye.

Automated quality inspection: Keeps your line running smoothly with minimal downtime.

These real-world implementations show how Jeenoce BondInspect fits perfectly into modern manufacturing lines, helping you catch defects early, improve yields, and protect profits.

At Jeenoce, we focus on smart manufacturing and automation solutions designed for today’s fast-paced SMT and semiconductor production lines. Our expertise in integrating non-standard automation equipment means we deliver AOI systems tailored to your specific needs—especially for bonding processes.

What Sets Us Apart

| Feature | Jeenoce BondInspect AOI | Traditional AOI Systems |

|---|---|---|

| Custom SMT Line Integration | ✔️ Specialized integration to fit your line perfectly | Limited flexibility |

| Advanced 3D Bonding Inspection | ✔️ Precise wire bonding, die, and loop profiling | Standard 2D optical inspection only |

| AI-Powered Defect Detection | ✔️ Faster, smarter defect classification | Manual or simple algorithm-based |

| Local U.S. Support | ✔️ Responsive, knowledgeable team based in the U.S. | Limited or offshore support |

| Certifications | ✔️ ISO 9001. CE, and industry-specific certificates | Varies by vendor |

Hear From Our Customers

“Moving to Jeenoce’s BondInspect AOI improved our yield dramatically. The AI-based defect detection saved hours in manual checks, letting us meet tighter schedules without sacrificing quality.”

—Production Manager, Midwest Semiconductor Plant

“Jeenoce’s local support team helped us integrate the system quickly and kept downtime near zero during setup. That kind of service is invaluable.”

—Quality Lead, California PCB Manufacturer

Certifications You Can Trust

ISO 9001 Certified: Proven quality management

CE Marked: Meets safety and environmental standards

Industry-Standard Compliance: Suitable for semiconductor, SMT, and PCB assembly lines

Choosing Jeenoce means investing in reliable, advanced AOI equipment backed by a company dedicated to your production success. We bring innovation, support, and quality together—all tailored for the East and Southeast Asian manufacturing scene.

Getting started with the Jeenoce BondInspect AOI system is easy. We provide a clear setup guide and hands-on training to ensure your team can quickly operate the machine without hassle. Whether you’re integrating it into an existing production line or setting up a new bonding process inspection station, we’re here to make the transition smooth.

Our support goes beyond installation. Regular maintenance and diagnostics keep the AOI running at peak performance, minimizing downtime. The system includes built-in self-check tools to quickly identify issues and optimize inspection accuracy.

Have questions? Our expert support team is ready to help with any unique challenges you face.

Looking to expand your inspection capabilities? Check out our related products, such as AOI solutions for PCB inspection and advanced optical quality control equipment, designed to work seamlessly with the BondInspect system.

Ready to improve your bonding process inspection with reliable support every step of the way? Let’s get started.

High-resolution camera with millions of pixels accurately captures micron defects

Ultra-high frame rate camera supports real-time inspection in high-speed production lines to prevent missed defects

Multi-angle coaxial ring light source eliminates reflection interference to improve defect recognition rates

Our U.S.-patented algorithms automatically identify various defects using advanced vision technology

Continuously optimize the structural design and core algorithms of the equipment based on the feedback of global users

Aim for zero error rates through continuous iteration of AI, deep learning, machine vision, and other emerging technologies

Our team of world-class engineers offers global technical support

Identify potential risks in advance to avoid losses caused by defective products flowing into production

Support reverse traceability from finished products to raw materials to quickly locate the root cause of the problem

By accumulating production data and customizing algorithms, we continuously optimize inspection strategies

By providing solutions that assure clients of our ability to meet yield rate requirements

Message