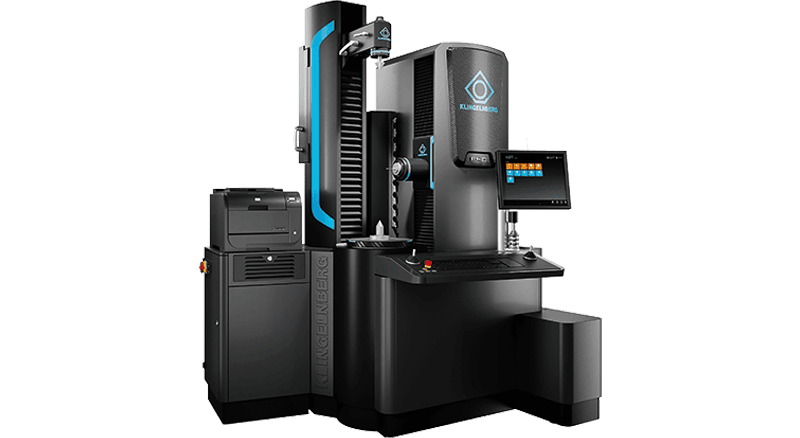

At Jeenoce, we understand the critical role precision plays in gear manufacturing. Our advanced gear inspection equipment and gear measuring instruments deliver unmatched accuracy, helping you maintain top-notch quality and consistency throughout production. Whether you work with spur gears, helical gears, or complex custom profiles, our solutions provide clear, reliable data to optimize every step of your process.

Why precision matters:

Ensures proper gear function and longevity

Minimizes costly rework and scrap

Supports compliance with tight industry standards

Our cutting-edge gear metrology systems and CNC gear analyzers combine robust hardware with intuitive software, making gear profile measurement and backlash inspection faster and more precise than ever. From pitch diameter gauges to automated gear checkers, Jeenoce equips your quality control team with the tools they need to deliver excellence confidently.

Explore how Jeenoce’s precision gear measuring equipment can elevate your manufacturing quality—where accuracy meets efficiency for smarter, smarter gear inspection.

Jeenoce offers advanced gear inspection equipment and gear measuring instruments designed for precision, reliability, and ease of use. Our smart manufacturing roots mean every product integrates cutting-edge automation with practical usability. This ensures you get accurate, repeatable results without the hassle.

Core Value Proposition

Accuracy: High-precision gear profile measurement tools and pitch diameter gauges guarantee measurement reliability.

Versatility: From spur gear inspectors to helical gear metrology instruments, we cover various gear types and sizes.

Automation: Automated gear checkers and optical gear scanners speed up inspections, reducing downtime.

User-Friendly Software: Intuitive interfaces and real-time data output simplify analysis.

Durability: Built with robust hardware for consistent performance in busy production environments.

Key Differentiators

| Feature | Jeenoce Gear Solutions | Typical Competitors |

|---|---|---|

| Measurement Accuracy | 0.0003mm | 0.005mm |

| Automated Inspection | Yes | Limited |

| Software Integration | Seamless with CNC and factory systems | Manual data export |

| Supported Gear Types | Bevel gear,Cylindrical gear,Shaft,Roughness,Contour,Optical measurement | Mainly spur and helical |

| Maintenance | Remote support and easy upgrades | On-site service only |

Our solutions fit perfectly whether your focus is on gear tooth measurement, backlash measurement devices, or comprehensive gear quality control equipment.

Explore how our products meet diverse manufacturing needs on our gear solutions and industry applications page.

Our gear inspection equipment and gear measuring instruments are designed to deliver precision, versatility, and reliability for a wide range of applications. Below is the detailed breakdown of our model lineup, measurement capabilities, and hardware specs.

Modular range | 0.30-20 mm(0.1-20 mm)*2 |

Horizontal measuring range | ±115 |

Maximum diameter of workpiece | 400mm |

Maximum moment of inertia allowed | 5kgm² |

Maximum permissible workpiece weight | 300kg |

Vertical measuring range (Z-axis) | 550(700)mm*7 |

Center distance | 50-800(50-1000)mm*7 |

Gear measurement according to VDI/VDE 2612 SHEET6*6 | Class A |

Total load of the equipment | 0.7kVA |

Equipment net weight including standard components | 2150kg |

Equipment dimensions (length × width × height) | 1535×1630×2200(2350)mm |

Dimensional and Performance Limits

Our gear measuring instruments can handle small to large gears across various industries thanks to their broad dimensional range. Performance remains consistent even at high-speed automated checks, ensuring enhanced throughput without sacrificing accuracy.

This comprehensive technical specification empowers users to select the ideal gear metrology system tailored to their production and quality assurance needs.

Understanding gear inspection equipment and gear measuring instruments means knowing the measurement methods behind them. At Jeenoce, we use a blend of advanced technologies to deliver precise gear measurement results every time.

Step-by-Step Process Guide

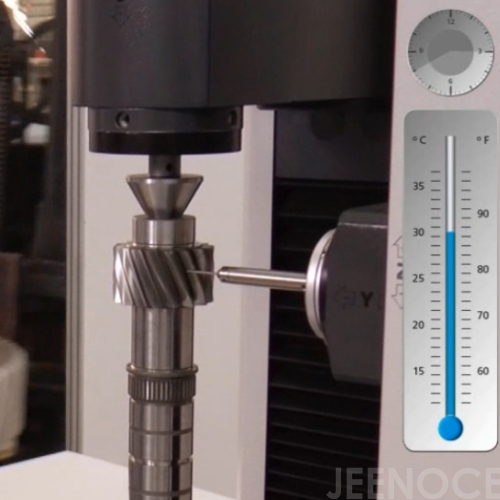

Initial Setup: Position the gear on the CNC gear analyzer or optical gear scanner to ensure stable and accurate readings.

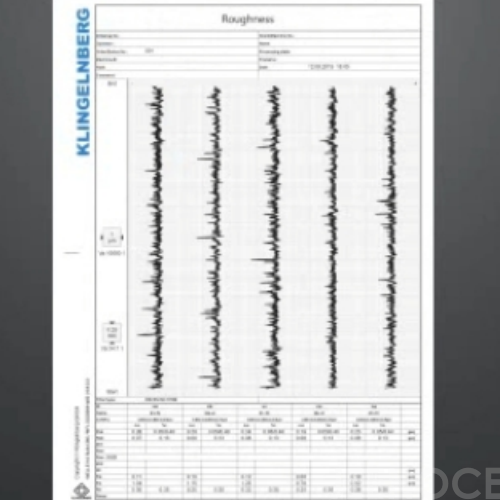

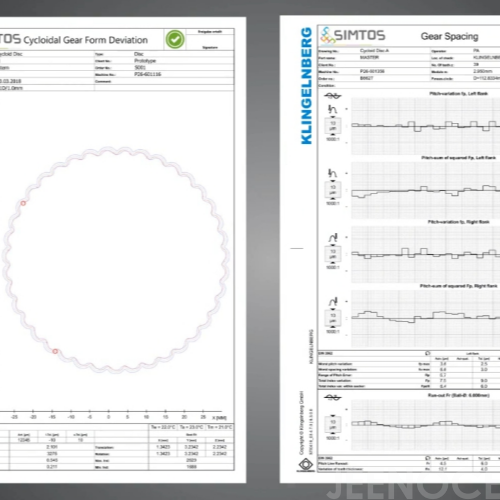

Data Capture: Use high-resolution sensors or optical cameras to measure critical parameters such as tooth thickness, pitch diameter, lead, and runout.

Profile Measurement: Employ gear profile measurement tools that scan each tooth for shape and contour accuracy.

Backlash Measurement: Specialized gear backlash measurement devices check clearance between mating gears to ensure proper fit.

Functional Testing: Use precision gear testers for dynamic inspection, examining how gears perform under operational stress.

Analysis: Software compiles the measurement data, providing detailed reports on dimensional accuracy, surface quality, and performance metrics.

Advanced Techniques Covered

Automated Gear Checking: Automated gear checkers speed up inspection with minimal manual intervention.

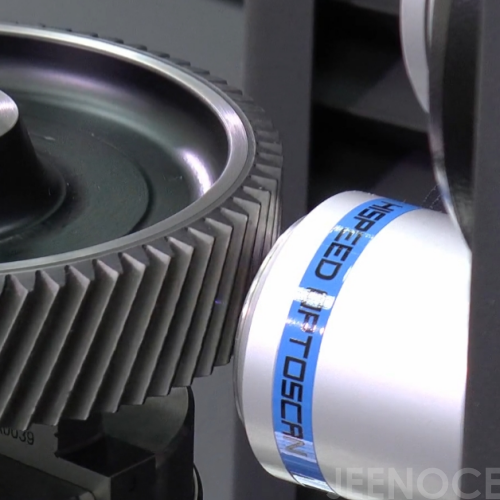

3D Optical Scanning: Optical gear scanners capture a complete 3D profile for comprehensive analysis.

Lead Inspection Machines: These focus on assessing the axial alignment of helical gears.

Runout Checkers and Tooth Thickness Calipers: Ensure concentricity and tooth uniformity with precision tools.

Pro Tips for Accurate Gear Measurement

Always calibrate equipment before inspections to avoid measurement drift.

Use environmental controls to reduce temperature or vibration effects.

Regularly clean measuring instruments to ensure sensor accuracy.

Combine multiple methods (optical, tactile, and functional) for comprehensive gear quality control.

Our gear metrology systems are designed to simplify complex inspection processes, ensuring you get reliable and repeatable results with every measurement.

Our gear inspection equipment and gear measuring instruments make a real difference across multiple industries. They ensure precise gear measurement, helping businesses maintain tight quality controls while boosting efficiency.

Primary Industries Served

Automotive: Precision gear testers ensure reliable transmissions and smooth engine performance.

Aerospace: High stakes call for top-tier gear profile measurement tools to meet strict safety standards.

Manufacturing: Automated gear checkers speed up quality control on production lines.

Energy: Gear runout checkers and backlash measurement devices enhance the durability of turbines and generators.

Robotics: Spur gear inspectors and helical gear metrology instruments optimize gear function and longevity.

Case Studies Snapshot

| Industry | Challenge | Solution | Outcome |

|---|---|---|---|

| Automotive | Reducing gear backlash variability | Lead inspection machines with CNC gear analyzers | 30% less rework, improved reliability |

| Aerospace | Ensuring pitch diameter accuracy | Optical gear scanners with gear tooth measurement | Compliance with aerospace fed standards |

| Manufacturing | Faster gear inspection cycles | Automated gear checkers and precision gear testers | 25% increase in throughput |

Benefits of Using Jeenoce Gear Solutions

| Benefit | Description |

|---|---|

| High Accuracy | Consistent, reliable gear measurement across all models |

| Time Efficiency | Rapid measurement reduces production downtime |

| Easy Integration | Compatible with existing CNC and inspection workflows |

| Versatile | Suitable for multiple gear types including spur and helical |

| Industry Compliance | Aligns with ISO and other global standards |

Jeenoce’s gear quality control equipment stands out by delivering precision, speed, and adaptability that meet real-world demands.

Ready to boost your gear inspection accuracy and streamline quality control? Explore Jeenoce’s full range of gear measuring equipment and gear inspection instruments designed to meet your production needs. Whether you’re upgrading your workshop or scaling your operations, our solutions help you stay ahead in precision gear measurement.

Explore Related Products

Semi-automatic gear testers

CNC gear analyzers

Optical gear scanners

Get Started Today

Request a demo

Contact our technical support team

Download product brochures

Optimize your gear quality control with tools engineered for accuracy, durability, and ease of use. Visit our homepage for more options and detailed info on Jeenoce gear inspection equipment.

When it comes to gear inspection equipment and gear measuring instruments, Jeenoce stands out thanks to years of industry experience and a strong focus on quality. We specialize in smart manufacturing and automation solutions, making us a reliable partner for precise gear metrology systems tailored to your needs.

Our Brand Story and Expertise

Jeenoce combines deep technical knowledge with innovative automation technologies. Our team develops advanced gear measuring tools, including CNC gear analyzers and optical gear scanners, to ensure the highest accuracy and efficiency in gear profile measurement. We’re proud to support manufacturers in achieving flawless gear inspection methods and precise gear pitch measurement.

Quality Assurance

Rigorous testing standards for every product

Use of premium components in gear runout checkers and backlash measurement devices

Continuous software updates to improve gear quality control equipment

Compliance with industry standards to guarantee reliable, repeatable measurements

Sustainability Commitment

We understand the importance of sustainable manufacturing. Jeenoce integrates energy-efficient designs and eco-friendly materials within our gear measuring machines, reducing environmental impact without compromising performance.

What Customers Say

“Jeenoce’s gear inspection equipment has improved our production accuracy and reduced downtime. Their expert support and quality assurance are unmatched.” – Manufacturing Lead

Jeenoce Gear Solutions at a glance:

| Feature | Benefit |

|---|---|

| Advanced gear testers | Accurate gear tooth measurement and inspection |

| Automated gear checkers | Streamlined quality control workflow |

| Customizable solutions | Tailored to specific gear metrology needs |

| Expert technical support | Smooth implementation and maintenance |

Choosing Jeenoce means choosing precision, reliability, and sustainability in gear measurement equipment.

At Jeenoce, we don’t just sell gear inspection equipment and gear measuring instruments—we partner with you every step of the way. From your initial purchase to full production integration, our team ensures a smooth setup and ongoing support.

Easy Installation and Setup

Our gear measuring machines come with clear installation guides designed for quick deployment. Whether you’re adding a single unit or a full metrology system, we provide step-by-step instructions, remote assistance, and on-site training options tailored to your needs.

Maintenance and Upgrades

Keeping your gear measuring tools calibrated and updated is key to precision. We offer regular maintenance packages and software upgrades that improve functionality and add new measurement methods—helping you stay ahead in gear inspection technology.

Professional ROI Analysis

Curious about how our equipment will boost your profitability? In our proposal, we will provide a detailed Return on Investment analysis, clearly illustrating the specific financial benefits gained from reduced inspection time, lower scrap rates, and improved product quality. Our goal is to support your strategic investment planning and give you clear foresight into your returns.

FAQs Section

We know gear measurement can involve many specifics. Our FAQs cover common questions like how to measure gear backlash accurately, tips on pitch diameter gauges, and troubleshooting advice for automated gear checkers. This resource supports your team for smooth daily operations.

This approach ensures you get full support with your Jeenoce gear metrology systems—from first setup to ongoing precision and productivity.

Various high-precision sensors (3D nanoprobes) work together to ensure accurate initial data

Temperature compensation technology can ensures stable operation in production workshops with temperatures ranging from 15 to 30°C

Heavy-duty and stable cast iron bed and direct drive motor guide rails ensure no gap measurement

Reserved load balance impact for error caused by workpiece loading

Intelligent control systems and algorithms refine data integrity

Real-time calibration of the influence of environmental temperature changes on measurement accuracy

Normal operation in factory production environments with vibration and dust

Contactless measurement is used to measure gears with soft materials,coatings, high-precision polished gear surfaces, and complex or fragile structures

The contact track of gear meshing is restored through dense data points,which is suitable for dynamic performance testing of high-precision gears in aerospace and other industries

It has a natural advantage in measurement scenarios with high levels of contamination, such as dust and oil pollution,cylindrical gear pitch measurement in compliance with VDI/VDE 2613 Class 1 standards,reducing inspection time by up to 80%

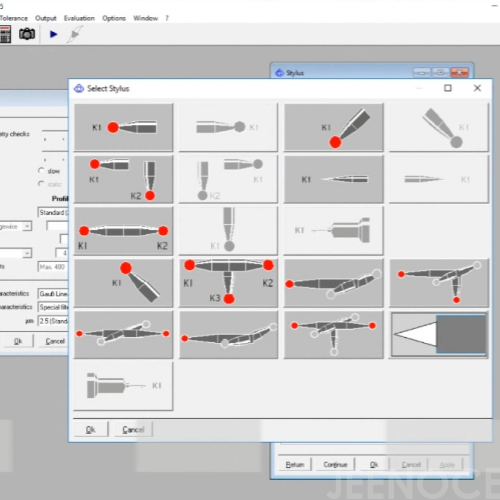

The user interface is simple and intuitive,high user acceptance,and simple training can be used

Password settings can protect different operational data,extremely high security

The tree-structured logic to easily create detection tasks

Enhance noise prediction and reduce quality standards

Accurate and repeatable measurements

Explore the root of the ripple degree to analyze whether the electric vehicle gear is complete

The simulation of the measurement process can be used for predictive analysis to identify potential issues in advance

The report can output the measurement results of full gear parameters

It displays the results graphically through 3D chromatograms, gear profile/tooth direction error curves, contact spot heat maps, etc.

Real-time report output and long-term traceability of data

The measurement results are in line with international testing standards to meet the strict requirements of high-end industries such as aerospace

Message