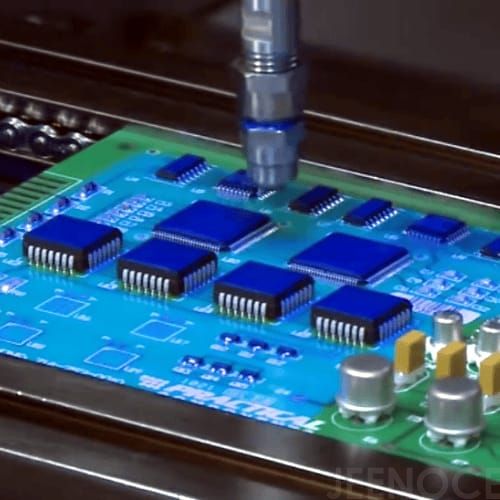

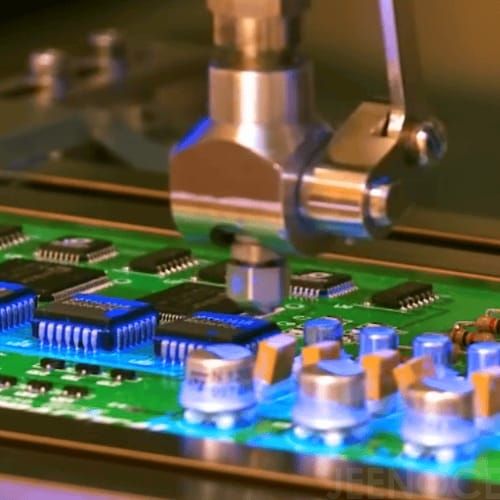

The coating system is the final step in the SMT assembly process. It typically works in conjunction with the dispensing process to extend product life by applying a protective layer on the surface,Jeenoce has introduced a coating system imported from the United States into its SMT full-line solution, primarily targeting high-end industries such as military electronics, new energy automotive electronics, medical electronics, aerospace electronics, and others,which require high precision and need to adapt to the strict environment of high standards.

Coating processes generally include several types, such as spraying, dipping, brushing, and selective coating,mainly according to the different circuit board products derived from the coating process.

Spraying:As the name implies,it is directly sprayed on the surface of the product by spray nozzle or spray head in the way of aerosol,which is commonly used in the electronic industry or some manufacturing industry with low quality requirements.

Dip coating:Similar to an immersion method, the circuit board is immersed in the coating material, so that each part of the circuit board is in contact with the coating material and then taken out and set aside. Generally, the circuit board with low added value and simple structure is used.

Brush coating:With our daily see "brush paint" is similar, in the electronic industry this manual coating method is mostly used in the laboratory, maintenance, local filling, is not suitable for large-scale industrial production.

Selective coating:The coating system introduced by Jeenoce is mainly realized in this way,which is also the standard process of automatic production in the electronic processing industry,through automatic equipment,such as industrial robots,the coating is directed for some areas that need to be protected by programming,so as to ensure the long-term stability of high-precision products in the later use.

Dispensing Process | Coating Process | |

Primary Purpose | To bond, seal, or fill structural components or parts using adhesives, primarily to fix and seal chips and enhance structural stability | Primarily for surface protection, providing waterproofing, dust resistance, corrosion resistance, and insulation by applying a coating to the surface to be protected |

Implementation Process | Primarily automated equipment

| Manual or automated equipment |

Consumed Materials | Viscous adhesives (e.g., epoxy resin, silicone) | Thin coating materials (e.g., acrylic, silicone) |

Complexity | High precision and complex

| Wide-ranging, with some simple methods

|

Of course,the application of the coating process is very wide,not only limited to the electronic industry, as mentioned above,the coating system introduced by Jeenoce is mainly aimed at the high-end electronic processing field to solve the problem of high precision coating,which is mainly for the protective effect,and the other is to meet certain industry standards, laws and regulations, and the appearance requirements of some products while ensuring protection.

The most basic protection is waterproof、moistureproof、dust resistance, anti-fog, and anti-chemical corrosion, etc. Whether it is 3C products or automobile manufacturing,these problems may lead to circuit boards and semiconductor chips in the use of the environment to cause a variety of circuit problems leading to major accidents,such as out-of-control vehicles,mobile phone explosion and other problems.

In addition,it is to protect the circuit board or semiconductor chip from direct damage to components such as temperature,collision and vibration.However,in general,the overall task of the coating process in the electronic field is to avoid functional damage of products due to the external environment,and then extend the service life as much as possible to bring customers a longer and stable service cycle.

Equipment Category | Functionality | Equipment Features | Problem Solved |

Conformal Coating Equipment | High-precision selective coating system supporting multiple coating materials (acrylic, silicone, polyurethane, etc.), with various spraying modes (e.g., mist, needle spraying) to meet diverse coating requirements | High-speed, intelligent, and precise control of coating position and thickness, avoiding uncoated areas, avoiding non-coating areas, and assisting in high-precision positioning | Moisture-proof, dust-proof, corrosion-resistant, and insulated, extending the lifespan of circuit boards |

Liquid Coating Equipment | LT: Manual powder spraying with 100kV static charging HD:HDLV® technology, providing a uniform low-speed powder cloud PE: Enamel powder coating,wear-resistant and corrosion-resistant | Quick material switching and simple maintenance | Enhances surface durability, aesthetics, and corrosion resistance |

Liquid coating equipment | Dual atomization technology, precise material control, continuous operation, and automatic cleaning, etc. | Specializes in liquid coating applications | Provides aesthetically pleasing, durable, corrosion-resistant surface coatings and localized protective functions |

Adhesive and sealant coating equipment | High-speed addition of coating materials, dual-channel precise metering control, suitable for complex high-precision application components | Precise control, reduced material waste, suitable for complex electronic packaging and battery module coating processes | Sealing and waterproofing, securing components |

UV curing system (compatible) | Rapid curing of UV coating materials | Reduced curing time | Enhanced production efficiency |

Non-contact coating thickness measurement equipment | Real-time measurement of coating thickness to ensure uniformity and quality | Real-time quality inspection to ensure coating effectiveness | Ensuring uniform coating and maintaining coating quality |

It can achieve accurate coating of millimeter or even micron level for complex structures and subtle areas

Through automatic control of various coating parameters to ensure that the overall quality is stable

Precise control of coating range and material dosage to minimize raw material consumption

It can easily handle the coating task of complex special-shaped circuit board, special material and special structure

The equipment has the ability of continuous operation to meet the needs of high-intensity mass production

Fast switching and continuous operation optimize the overall production process to improve the efficiency of production line operation

Near-zero downtime control reduces all aspects of cost consumption and additional expenses

Cope with a variety of production scenarios without pressure to significantly improve work efficiency

It can be compatible with acrylic、silicone、powder、adhesive and other coating materials

Complete the entire process from coating application to curing in a single unit

It is suitable for complex workpieces, precision parts and other diversified coating scenarios

Ensure that the coating of different materials and different processes can achieve stable quality standards

Significantly reduces materialloss in the coating process to improve resource utilization

The powder recovery system can recover and reproduce the unused powder

The standard environmental production mode of the original factory in the United States meets the requirements of relevant environmental laws and regulations

Message