The world's most accurate automatic dispensing system for process control

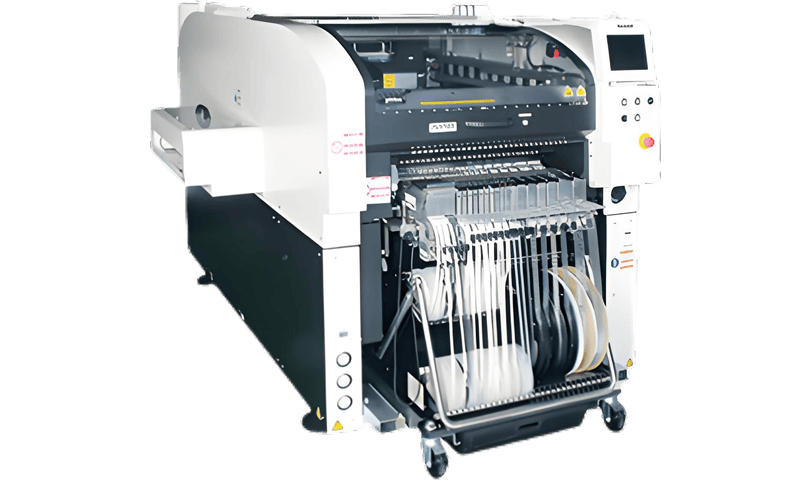

The automatic dispensing system is a set of integrated automatic equipment designed for accurately controlling the dispensing, coating, and potting of fluids (such as glue used in various SMT patch processing) on the surface or within the structure of electronic products.Jeenoce introduced this system, leveraging 60 years of experience from the original U.S. factory, with the goal of improving production efficiency, reducing manual errors, lowering glue consumption, and ensuring product quality for our customers in industries such as automotive, aerospace, medical, pharmaceutical, and high-end electronics manufacturing.