Welcome to the Jeenoce Vapor Phase Reflow Soldering System — a cutting-edge solution designed to simplify and enhance your PCB soldering process. Our vapor phase reflow oven delivers precise, consistent heat through a controlled vapor condensation method, ensuring high-reliability PCB soldering every time.

Built with advanced condensation soldering system technology, the Jeenoce vapor phase soldering equipment provides uniform temperature control that protects sensitive components and supports lead-free soldering standards. Whether you’re dealing with BGAs, fine-pitch components, or complex SMT assemblies, this system offers repeatable results with minimal thermal stress.

Key benefits include:

Accurate temperature profiling with condensation reflow profile control

Reduced risk of thermal damage and warping

Eco-friendly operation using non-toxic vapor phase soldering fluid like Galden

Compatible with a broad range of PCB sizes and materials

Discover how the Jeenoce system integrates seamlessly into your manufacturing line, boosts yield rates, and lowers rework costs while maintaining industry-grade quality. If you’re looking for reliable, professional vapor phase soldering equipment backed by technical excellence, Jeenoce is your trusted partner.

Vapor phase reflow soldering stands out for its precision, reliability, and eco-friendly process. Unlike traditional PCB reflow soldering equipment, vapor phase uses a controlled condensation soldering system. This means consistent heat transfer through saturated vapor, resulting in uniform solder joints with minimal risk of component damage.

Key Benefits

| Benefit | Explanation |

|---|---|

| Uniform Heating | Condensation reflow profile ensures even heat distribution for high-reliability PCB soldering. |

| Reduced Thermal Stress | Vapor phase avoids temperature overshoot, protecting sensitive components like BGAs. |

| Lead-Free Compatible | Ideal for lead-free vapor phase soldering, supporting modern eco-friendly manufacturing. |

| No Oxygen Exposure | Inert vapor soldering machine prevents oxidation, improving solder joint quality. |

| Energy Efficient | Lower power consumption compared to convection ovens, saving operational costs. |

Common Use Cases

SMT Vapor Phase Process for complex arrays like BGAs and fine-pitch components

Batch Vapor Phase Reflow in high-volume SMT production lines

Vacuum Vapor Phase Soldering where sensitive PCBs require precise atmosphere control

Repair and prototyping with compact vapor phase reflow ovens designed for quick cycles

Choosing vapor phase soldering means investing in consistent results and reduced rework rates. It’s no surprise it’s popular among manufacturers focused on quality, especially for lead-free applications.

Explore how our solutions fit into your production in our Industry Solutions section.

Why is vapor phase soldering of higher quality than gas or liquid medium soldering?

Vapor phase soldering uses a unique condensation soldering system to deliver precise, even heat during PCB assembly. Here’s a simple step-by-step breakdown of how the vapor phase reflow process works:

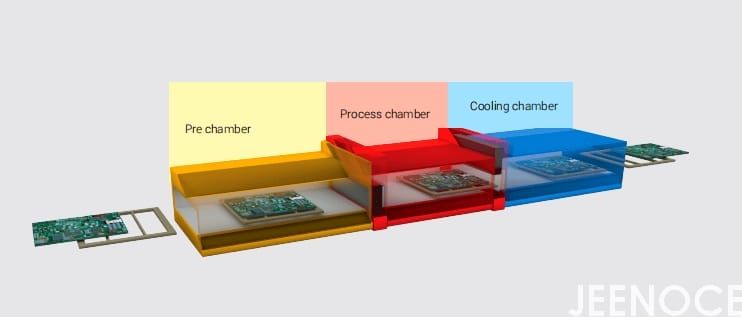

Preparation: The printed circuit board (PCB) loaded with components is placed inside the vapor phase reflow oven, like the Jeenoce CondensoXS.

Heating with Vapor: The oven is filled with a specially selected vapor phase soldering fluid, often a heat transfer liquid such as Galden fluid. This fluid is heated to a controlled temperature above the melting point of solder but below the damage threshold for components.

Condensation Process: As the heated vapor rises, it condenses onto the cooler PCB surface. This condensation releases latent heat very efficiently, providing uniform heating across all areas of the board.

Solder Melting and Reflow: The precise temperature plateau created by the vapor enables the solder paste to melt smoothly, ensuring reliable wetting and strong solder joints without overheating or thermal stress.

Automatic Cooling: Once the solder reflows, the vapor supply stops, and the board cools naturally at a controlled rate, cementing the component connections and preventing warping or damage.

This inert vapor soldering machine method offers an eco-friendly reflow soldering alternative with highly repeatable condensation reflow profiles, making it ideal for high-reliability PCB soldering in modern SMT production.

CondensoXS Specifications: Built for Demanding SMT Production

The Jeenoce CondensoXS vapor phase reflow soldering system is engineered for high-reliability PCB soldering, perfectly suited for modern SMT lines needing precision and consistency. Designed as a top-tier condensation soldering system, it supports both lead-free vapor phase soldering and standard profiles.

| Feature | Specification | Benefit |

|---|---|---|

| Heating Fluid | Galden or compatible inert vapor soldering fluid | Eco-friendly, stable thermal transfer |

| Process Modes | Batch vapor phase reflow & vacuum vapor phase soldering | Flexible for diverse process needs |

| Reflow Profile Control | Automatic condensation reflow profile | Consistent solder joints, reduced risk of overheating |

| Vacuum Capability | Optional vacuum subsystem | Minimize voids in BGAs and fine-pitch components |

| Cycle Time | 10-15 minutes per batch | Efficient throughput for volume production |

| User Interface | Touchscreen HMI | Easy programming and monitoring |

This vapor phase reflow oven also integrates with inline vapor phase ovens for streamlined production setups. Its robust design handles high-volume PCB reflow soldering equipment needs without sacrificing quality or reliability.

Choose CondensoXS for a condensation soldering system that meets demanding SMT production with stable, eco-friendly, and flexible vapor phase soldering profiles.

Jeenoce’s vapor phase reflow soldering system fits seamlessly into diverse electronics production lines. Whether you’re working with high-reliability PCB soldering for aerospace, automotive, or medical devices, the system handles complex assemblies like BGAs and fine-pitch components with ease. Its compatibility with lead-free vapor phase soldering meets current environmental standards while ensuring consistent solder joints.

Key applications include:

SMT vapor phase process for small to large batch PCB assembly

Condensation soldering system ideal for delicate or heat-sensitive components

Inline vapor phase oven setups for high-volume production lines

Soldering of multi-layer, high-density PCBs requiring precise temperature profiles

Plus, the system supports various vapor phase soldering fluids, including eco-friendly options like Galden fluid for reflow, enabling clean, efficient processing. For manufacturers seeking flexible vapor soldering equipment that adapts to evolving SMT needs, Jeenoce offers reliable solutions tailored to modern electronics demands.

Explore how our technology integrates with your production needs on our careers and company overview pageand see how our team supports these advanced applications.

Keeping your vapor phase reflow soldering system running smoothly is easy with Jeenoce. Our jeenoce vapor phase soldering equipment requires minimal maintenance thanks to robust design and smart features that reduce downtime.

We provide high-quality vapor phase soldering fluids like Galden fluid for reflow, specially formulated for consistent condensation soldering profiles and reliable lead-free vapor phase soldering results. Our fluids are eco-friendly and optimized for long life, cutting operating costs and environmental impact.

Jeenoce also offers a full range of accessories and replacement parts to keep your vapor phase reflow machine performing at its best. From filtration systems to vapor phase soldering profiles presets, we support your SMT vapor phase process every step of the way.

Our expert technical team is ready to assist with setup, fluid handling, and preventive maintenance, ensuring your investment in vapor phase soldering technology delivers ongoing value. Discover more about our team and service commitment on the Jeenoce talent and team page.

Jeenoce vapor phase reflow soldering systems have earned trust across various industries thanks to their consistent, high-quality results. Customers report remarkable improvements in solder joint reliability, especially with complex PCBs and sensitive BGAs. The condensation soldering system’s ability to deliver a stable temperature profile results in fewer defects and less rework compared to traditional reflow ovens.

Many users highlight the ease of switching to lead-free vapor phase soldering, appreciating both the environmental benefits and excellent solderability. Our inert vapor soldering machine minimizes oxidation, making it ideal for high-reliability PCB soldering applications where quality cannot be compromised.

Key customer feedback includes:

Improved production yield due to uniform heat distribution

Reduced maintenance time with the closed-loop system using Galden fluid for reflow

Versatile use across batch vapor phase reflow and inline vapor phase oven setups

Eco-friendly benefits with lower energy consumption and clean soldering process

You can explore more about how our vapor phase soldering equipment transforms SMT production in our detailed insights on Jeenoce’s intelligent vapor phase solutions. The real-world success stories reflect why many choose Jeenoce as their trusted vapor phase reflow vendor.

Choosing the right vapor phase reflow system means balancing quality, cost, and your production needs. The Jeenoce CondensoXS offers flexible pricing options tailored for small to large-scale PCB soldering lines.

| Model | Features | Price Range (USD) | Suitable For |

|---|---|---|---|

| Standard | Batch vapor phase reflow | Contact for quote | Small & medium SMT production |

| Pro | Inline vapor phase oven | Contact for quote | High-volume & inline use |

| Customized Units | Lead-free & vacuum options | Contact for quote | Specialized reflow profiles |

Why invest now?

Lower rework rates with precise condensation soldering

Eco-friendly vapor phase soldering fluids like Galden ensure safe operation

Durable equipment designed for long-term industrial use

Access to expert support and accessories for smooth operation

Ready to enhance your SMT process? Contact us to get a clear, customized quote based on your production scale. Discover how our condensation soldering system fits your needs and budget perfectly.

Take the next step toward reliable, efficient vapor phase reflow soldering today!

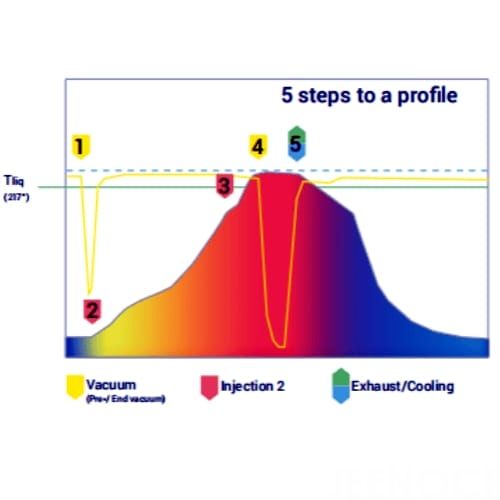

The temperature curve is precisely controlled by controlling the content of the gas phase liquid according to the process stage

It can meet the soldering requirements of almost all temperature sensitive components with guaranteed quality

The patented technology ensures uniform temperature distribution between the soldering surface and the structure

The peak temperature of lead-free material is stable at 230-240℃ to avoid the influence of high temperature

The minimum void rate can reach less than 1%, suitable for aerospace、automotive and other fields of large circuit board soldering requirements

Equipped with recycling systems and filters to reduce material waste and component replacement frequency

99.9% of the vapor liquid can be recovered and purified for secondary use to save costs

Galden® liquid does not have any impact on the environment and does not require post-treatment costs

Strict control of temperature changes saves long-term power usage costs

Three-stage furnace distributed intermittent injection of inert gas to maintain oxygen content < 100ppm environment

The fifth generation vacuum process of gas phase soldering in Germany controls the pressure curve to avoid splashing of solder

It is suitable for void-free soldering scenarios such as BGA components and power electronics DCB substrates

It has a very obvious advantage for MID and other 3D complex structure soldering

The gas phase soldering system introduced by Jeenoce is fully compliant with the Montreal Protocol and RoHS regulations

It complies with the requirements of the EU WEEE Directive on waste minimization by reducing the carbon footprint

The latent heat transfer efficiency of VPS is about 10 times higher than that of traditional convective reflow to further save energy

The anaerobic environment and cleaning process of VPS meet the emission standards of EU REACH regulations

Real-time monitoring of key parameters through touch screen interface to reduce soldering defects

ViCON software integrates MES (Manufacturing Execution System)to trace production issues

Optimize the production process by recording and storing all process data through the system

Adjust material usage in real time during soldering process to reduce error costs

It has various operation functions such as adding taskbar, structural parameters, independent process and archiving

Message