Just as its name implies, customized automation equipment is customized rather than standardized, which can realize automatic functions.

As production processes evolve, manual labor struggles to meet precision requirements, necessitating mechanical solutions.

Moreover, shifts in the labor market drive up recruitment costs and make hiring more challenging.

Jeenoce has assembled a team of senior engineers from leading non-standard automation plants in Europe and the US to deliver cost-effective solutions.

Essentially, customized automation equipment refers to devices tailored by an engineering team using software and hardware to meet your specific needs.

These devices are designed to address challenges in unique scenarios.

For example, when the manual operation can not meet the precision requirement, when increasing production capacity but is limited by the complexity of production process, when attempting to replace expensive labor to reduce cost,etc.

In contrast, standard automation equipment consists of pre-configured products designed for common industry processes and workflows.

Its basic internal structure, working principle, processes flow and even appearance are all fixed,when compared with the standard automated equipment, the customized possesses relatively great degree of flexibility,allowing it to solve current problems based on actual conditions without the need for additional processes,thus greatly reducing costs.

The first consideration is:‘Can this company or team handle my problem?’Specifically,‘Can they meet my product process requirements, technical specifications, and ensure solution stability and performance?

This depends on the team’s capability.

At Jeenoce, our experienced engineers from leading plants ensure there are no technical limitations.

And then the second step is to consider the price,the quality of after-sales service and whether the security protection is in place.

Of course, there is no need taking a non-standard automation company with security risks into consideration,because no matter what all designs must be people-oriented,and people are the most significant part of all social activities.

Customization

It is the first issue of the non-standard automation equipment project, which is also the core feature,the customized equipment must be designed entirely around your“specific needs", including the design, functions, dimensions,features,interfaces, etc.

Uniqueness

It is usually designed and customized for solving specific problems and put forward requirements, In most cases, the quantity of such equipment is small, basically designed for one or several units in small batches.

Capability to meet special production processes

The processing, assembly, testing, handling and other processing techniques of many products may be confidential and not demonstrated to the public.

Therefore, the difficult to operate and inefficient parts will be finished or replaced by customized transformation.

Integration

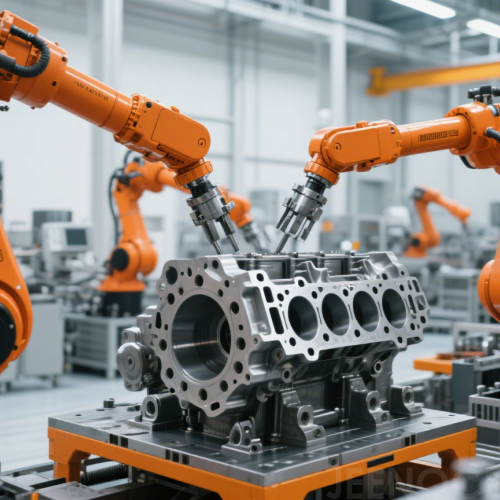

Non-standard automation equipment is a kind of brand-new device but is also assembled by many standardized components,such as motors, sensors, controllers, pneumatic components and others are integrated with the customized mechanical structures, software (or logic processes), just like assembling Lego blocks.

Specificity

As mentioned above, the non-standard automation equipment is specifically designed to solve specific issues,Therefore,if the product or manufacturing process changes,these devices may need to be modified or re-designed.

Step one: Holding a client meeting for deep exploration of their needs

In order to fully understand your specific requirements in terms of production processes, product features, site layout, production capacity goals, budget range and other details,as well as the pain points that need to be resolved in the current production process,Jeenoce will organize a professional team to communicate with your company’s technical engineers about all the details before the project starts.

Step two: Demonstrating strength by presenting relevant cases

Based on your needs,we will conduct the detailed review of technical solutions, equipment configurations, implementation processes and eventual results in past cases when facing similar needs and issues,Meanwhile, this will also be reference and formulation of new solutions.

Step three: Determining the technical agreement and customize exclusive solutions

After the final technical agreement is determined with the above steps, the technical team will start customizing possible solutions for you,The solution will cover detailed information such as the function design of equipment, technical parameters, process flow, production cycle, cost budget and other details,Later,the specific effects will be displayed to you directly by simulation demonstrations and other methods.

Step four: Listening to the client feedback during project verification stage

After the project proposal is submitted to the client,and needs to offer your opinions and suggestions on the feasibility, rationality and economy of the solution from your own perspective of your practical need and usage. Jeenoce will arrange certain personnel to maintain close communication with you,answering problems in time and continuously optimizing the solution.

Step five: Perfecting the solution to achieve the highest satisfaction

Jeenoce will organize personnel from technical, design, production and other departments personnel to comprehensively revise the proposal based on your feedback,the mainly include technical details, equipment configuration, cost budget and other contents will be adjusted and optimized until you are satisfied with it.

Step six: Ensuring qualified quality after verification

After the plan is determined,Jeenoce will strictly follow of the plan to product and manufacture the automated equipment.

During production process,Jeenoce will strictly control the quality including the inspection of every component and every process.

After the equipment is manufactured, Jeenoce will invite clients to conduct on-site tests,and you can comprehensively inspect the equipment’s functions, capability, precision,stability and other possessions according to your own standards.

Throughout the process and promptly rectify any problems found,we will fully cooperate with customers in the testing work, during which will ensure that the equipment production fully complies with the delivery standards.

Non-standard automation equipment is almost applicable to all industries,with more emphasis on the products it can adapt to or the problems it needs to be solved,mainly existing as a certain module of automation processes or automated production lines,or some specific usage purposes.

Automated production lines

Specifically designed for the production assembly, soldering, inspection,marking and packaging of specific products are basically non-standard and customized.

Specialized process testing equipment

Devices for testing the performance, reliability and lifespan of specific products, such as test chambers that simulate specific environmental conditions,and product function integration test benches.

Specialized processing equipment

Machine tools or tooling fixtures for production components with special shapes, materials or precision requirements.

Material handling and processing

Handling, sorting and palletizing equipment that operates in the specific spaces and with materials (such as fragile,high-temperature,and irregularly shaped).

Experimental setup

A dedicated platform established by scientific research institutions or enterprise R&D departments for specific experiments.

A team of over a hundred senior engineers who has been deeply involved in the world-class non-standard automation projects

Optimal solutions will be matched whether it is a complex technical challenge or a specific scenario requirement

Covering talents from multiple fields such as mechanics, electronics, software industries, etc to provide wiht all-round technical support for clients

Strictly adhering to the delivery standards of German enterprises to deliver reliable non-standard automation equipment to clients

Accurately grasping the pain point of the industry and swiftly adapt to clients’ complex requirements

The perfect integration of non-standard automation equipment with the clients’ existing system avoids information blockade

Accurately avoiding ineffective expenditure to save real money for enterprises

Providing clients with predictable investment return rates and clear cost-benefit of analysis

Strictly following various domestic and international standards and specification for equipment research and develop as well as manufacturing

Quickly sorting out the architecture and operating logic of existing production lines to realize seamless coordination among all links

Fully considering individual characteristics of different customers and flexibly meet diverse production needs

Deeply optimizing production process, data interaction and other system-level operations to improve production efficiency

Saving a large amount of ineffective expenditures for clients by precise line integration solutions

Responding immediately without wasting a single second of the customers

Professional team is always online for response to ensure worry-free production and operation

Exclusive engineers will contact with customers in a deep and point-to-point,avoiding information misunderstandings

Adjusting the technical solution at any time to the orientation of customers’satisfaction

Message