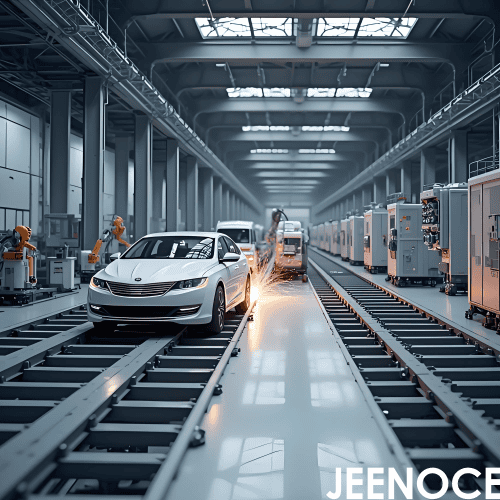

Imagine your production floor running smoother, faster, and smarter. Our automated assembly line delivers just that. Packed with advanced robotics and AI-powered quality control, it’s designed to boost your throughput by up to 300%, while pushing defect rates below 0.5%. Whether you’re scaling up or tackling complex assembly tasks, our modular system offers seamless scalability to meet your evolving production needs.

See the line in action with our eye-catching header image showcasing precision robotic assembly and streamlined workflow. Ready to transform your manufacturing? Request a custom quote today and take the first step toward automated efficiency.

Jeenoce’s modular automated assembly line is built to fit your production needs, whether you’re in electronics, consumer goods, or medical devices. Designed with flexibility in mind, it lets you scale up or adjust quickly without major downtime. The system features real-time monitoring to keep you updated on every step, plus easy integration with your existing smart manufacturing line. Whether you need precise SMT production line capabilities or non-standard assembly robots, Jeenoce’s solution adapts to your workflow for smoother, faster assembly.

Our automated assembly line comes loaded with features that make your production smarter, faster, and more reliable.

Robotic Precision Assembly

Cobots handle pick and place tasks with high accuracy, cutting down errors and speeding up workflows.

Conveyor and Pallet Transfer

Smooth, automated movement of parts keeps everything flowing without delays or bottlenecks.

AI-Powered Quality Control

Vision systems catch defects and leaks in real time, ensuring less than 0.5% faulty products.

Scalable Modular Design

Easily adjust your line for high mix, low volume runs — no need to overhaul for new products.

Benefits at a Glance

| Feature | Manual Assembly | Jeenoce Automated Assembly Line | Benefit |

|---|---|---|---|

| Cycle Time | Slow, varied | Up to 300% faster | Massive throughput boost |

| Defect Rate | 2%-5% | <0.5% | Fewer costly reworks |

| Scalability | Difficult, expensive | Modular, seamless | Adapt quickly to demand shifts |

| ROI | Longer payback | Faster, clear savings | Invest with confidence |

Switching to Jeenoce means less downtime, less waste, and a production line that grows with your business.

Hardware

| Feature | Details |

|---|---|

| Robot Payload | Up to 15 kg per arm |

| Conveyor Speed | Adjustable, up to 60 ft/min |

| Station Count | Modular, 5 to 20+ stations |

Software

PLC integration for real-time control

IoT connectivity for remote monitoring

5G compatibility ensures low-latency data transfer

Supports MES and ERP systems for streamlined operations

Customization Options

SMT-specific modules for surface mount technology

Reflow soldering stations for precise component attachment

Automated component feeders tailored to production needs

Safety and Compliance

Built to meet ISO robotics standards

CE and UL certified for industrial safety

Designed with fail-safe mechanisms and emergency stops

Our automated assembly line combines robust hardware with smart software and customizable features to fit your specific production needs while maintaining top-level safety and compliance.

Our automated assembly line makes production simple and efficient with clear steps you can count on:

Component Feeding

Parts are loaded automatically, keeping your line moving without delays.

Robotic Assembly

Cobots and robots handle precise pick and place tasks, ensuring consistent quality.

In-Line Testing

Each product is tested during assembly to catch defects early and reduce scrap.

Final Output and Packaging

Finished units are smoothly transferred and packed, ready for shipment.

We’ve helped companies across China, East Asia, and Southeast Asia boost their production with our automated assembly line solutions. One electronics manufacturer saw a 40% increase in uptime after switching to the Jeenoce SMT line, cutting defects by over 60%. Their production cycle time dropped from 20 minutes to just 7. thanks to our precision robotic assembly and AI-powered quality control.

Here’s what clients say:

“Jeenoce transformed our workflow, making it faster and more reliable.”

“The modular design fit right into our existing setup, and the ROI was quick.”

When it comes to automated assembly lines, Jeenoce stands out for good reason. Here’s why U.S. manufacturers trust us:

| Feature | What It Means For You |

|---|---|

| 20+ Years in Smart Manufacturing | Proven expertise to deliver reliable solutions |

| 500+ Global Installations | Tested and trusted worldwide |

| End-to-End Support | From setup to maintenance, we’ve got you covered |

| ABB Robotics Integration | Access to industry-leading robot tech |

| Certified & Award-Winning | Compliant with ISO, CE, UL standards |

We focus on real results—boosting your throughput, cutting defects, and scaling as your business grows. Our team understands local market needs and delivers automated manufacturing lines designed to excel in Southeast Asia’s diverse industrial environments.

Choose Jeenoce for an automated assembly system that’s reliable, scalable, and backed by proven experience and industry partners.

We offer tiered pricing plans designed to fit businesses of all sizes—from Starter packages to Enterprise solutions. Whether you’re just getting started with automated assembly or scaling up a full smart manufacturing line, there’s a plan built for you.

Our interactive ROI calculator lets you input your production volume and other key details to estimate your potential savings. This tool helps you see the real value of switching to Jeenoce’s automated assembly line, including faster cycle times and lower defect rates.

How long does it take to set up the automated assembly line?

Setup time varies depending on your production needs but typically ranges from a few days to two weeks. Our team works closely with you to ensure a smooth, fast installation with minimal downtime.

Can the line integrate with existing SMT production lines?

Yes, our modular automation equipment is designed for easy integration with current SMT lines. It supports seamless communication with your PLC, MES, and ERP systems.

Is the system flexible for different product types?

Absolutely. The robotic assembly system is built with scalable modules and cobot integration solutions to handle high mix, low volume production efficiently.

What kind of maintenance does the automated manufacturing line require?

Routine checks and software updates keep everything running smoothly. We also offer ongoing support and remote monitoring via IoT connectivity and 5G compatibility.

What safety standards does the line comply with?

Our automated production line meets ISO robotics standards and is CE and UL certified to ensure a safe working environment.

Can I customize modules for specific tasks like reflow soldering?

Yes, you can add or modify modules such as SMT specific components, reflow soldering stations, and specialized feeders based on your production needs.

How do I get a quote or demo?

Simply request a custom quote through our website or schedule a free consultation. We also offer an embedded demo video showcasing the line in action.

We have over 100 senior engineers with deep experience in world-class non-standard automation projects

Whether it is a complex process problems or special scenarios demand can be quickly matched with the optimal solution

Covering mechanical, electrical, software and other fields of talent to provide customers with a full range of technical support

We deliver reliable equipment that meets German enterprise standards

From full automation to semi-automation to adapt to the capacity needs of different industries and enterprises

A team of JEENOCE engineers can customize the solution according to the industry characteristics to reduce the cost of adaptation

Through the“modular tooling + program switching”to enhance the utilization of the equipment

Support for mixed-line production can be in the same line at the same time to deal with different products on the same line at the same time.

Dynamically adjusts production parameters to keep the production line running optimally around the clock

Timely discovery of product defects and corrections to reduce the rate of defective products to reduce the cost of rework and material wastage

Records and traces the information of materials, process parameters, operators, etc., in the whole process of production

Pre-empts the hidden danger of failures and proactively arranges for a maintenance plan to avoid sudden stoppages that lead to production interruptions

Lean manufacturing concepts throughout the entire design process to improve enterprise profitability

Tailor-made lean solutions to help customers achieve high-efficiency production goals at lower costs

Continuous optimization of the production system to help customers occupy a favorable position in the market competition

Comprehensive reliability analysis and cost-effectiveness considerations to achieve a balance between economy and excellence

Accurately grasp the industry pain points and quickly adapt to the complex needs of customers to provide efficient solutions

Custom-designed MES system significantly improves production management and reduces costs

Provide customers with predictable ROI and clear cost-benefit analysis to ensure the long-term benefits

Strictly follow the domestic and international standards and norms of R & D and manufacturing to ensure safety compliance

JEENOCE Positioning Solution Integrator can provide one-stop intelligent upgrading solutions according to your needs

Message