In the rapidly evolving automotive industry, side panel outer plates are critical components.

They provide structural integrity, ensure passenger safety, and contribute to a vehicle’s aesthetic appeal.

As consumer demand for diverse vehicle models grows, manufacturers face increasing pressure to deliver high-quality production while maintaining flexibility and efficiency.

A large new energy vehicle group, a leading Chinese new energy vehicle (NEV) manufacturer, encountered this challenge with their models A and B.

Production bottlenecks for side panel outer plates threatened their ability to meet market demands.

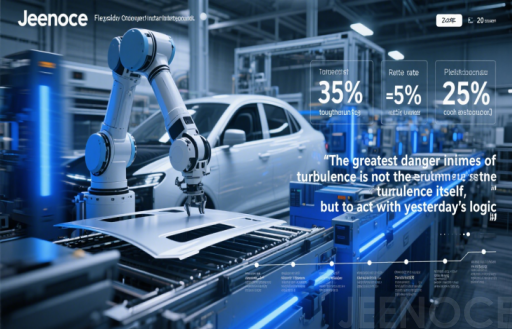

Jeenoce, with over 10 years of experience in custom automation designer, partnered with a large new energy vehicle group to address this issue.

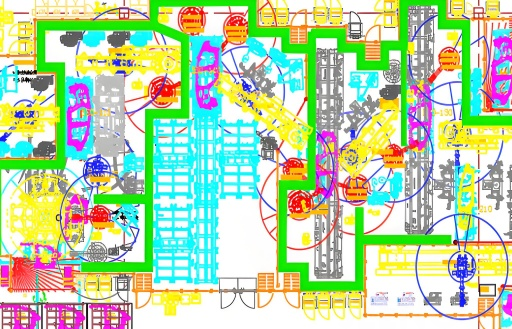

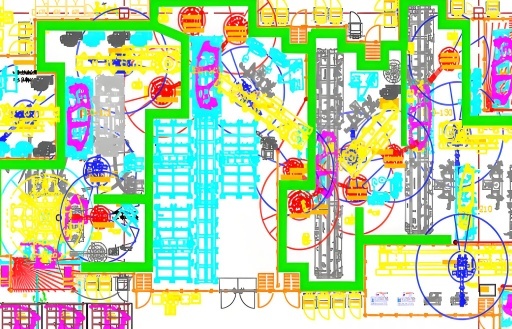

We developed the "Flexible Side Panel Outer Plate Intelligent Production Line" ,a state-of-the-art solution leveraging smart technology and customized equipment.

This automated assembly line not only resolved the large new energy vehicle group’s production challenges but also set a new standard for efficiency and adaptability in automotive manufacturing.

This case study explores how we designed and implemented this innovative system, delivering measurable results that strengthened the large new energy vehicle group’s position in a competitive landscape.

Jeenoce’s intelligent production line integrates advanced automation and smart controls, offering significant benefits for modern automotive manufacturing:

Real-time data monitoring and dynamic adjustments minimize downtime.

In mixed-model production where multiple vehicle models are manufactured on the same line, changing models requires adjusting the way equipment clamps and positions workpieces.

This set of customized equipment, through its high-precision mechanical structure combined with laser scanning recognition, achieves rapid adaptation to different vehicle models, reducing the lengthy model changeover waiting time in traditional production.

This enhances throughput by 35%. According to McKinsey’s 2023 report, smart manufacturing can improve efficiency by 20-30% (McKinsey & Company).

Jeenoce’s solution surpasses this benchmark, optimizing the automated assembly line for maximum productivity.

By improving the use of available resources and reducing the need for manual work, this method significantly lowers overall operating costs.

This approach not only streamlines operations but also ensures that resources are deployed more efficiently, allowing for savings that can have a positive impact on the financial bottom line.

Therefore, enterprises can devote more energy to strategically significant activities rather than getting stuck in time-consuming trivial tasks.

The magnetic levitation transport system, a key feature of our customized equipment, cuts energy consumption by 40%. On the automated assembly line, after robots perform precise operations, the defective rate of products has dropped from the original 15% to below 5%.

This improvement has reduced the large new energy vehicle group's annual losses caused by waste products by more than 2 million yuan. Deloitte’s 2024 report highlights that smart manufacturing can reduce costs by 20% (Deloitte), a target our solution exceeds.

Smart quality control systems ensure consistent, high-quality output.

Visual inspections paired with AR-assisted checks detect defects early.

At station BS0085, AR glasses and automated defect marking, integrated into the assembly line, reduce misses to 0.02%.

The system adheres to the IATF 16949 standard (IATF Global Oversight), guaranteeing that every side panel meets the automotive industry’s stringent requirements.

These advantages create an efficient, cost-effective production system tailored to the complexities of modern car manufacturing.

Designed specifically for side panel outer plate production, this intelligent automated assembly line excels in diverse scenarios:

The line supports mixed production for models A and B, accommodating 273 structural variations, such as 18 weld points for model A versus 16 for model B.

Customized equipment, like the RFID-driven quick-change clamping system, reduces switchover time to 15 seconds, ensuring flexibility for varied production needs.

The automated assembly line integrates effortlessly with welding, coating, and assembly stages.

At station BS0060, robotic coating pre-stations and quick-change grippers, part of our customized equipment, achieve ±0.3mm part placement accuracy.

Automated Guided Vehicles (AGVs) enhance material flow between stations BS00111 and BS01990, streamlining downstream processes.

For premium vehicle models with strict tolerances, the line delivers exceptional precision.

Welding robots offer ±0.02mm repeatability, while servo-driven coating guns, a customized component, provide ±0.1mm accuracy.

These features ensure flawless execution for tasks like 2486mm-long coatings.

These capabilities position the line as a vital tool for manufacturers navigating diverse market demands.

Jeenoce’s intelligent production line has proven its value across multiple clients:

The large new energy vehicle group faced challenges with multi-model efficiency and defect rates.

Our automated assembly line, equipped with customized equipment, increased output from 500 to 675 units per shift.

The defect rate dropped from 15% to below 5%, and model switchovers fell to 15 seconds.

New model launches accelerated by 30%.

With a 36 million RMB investment, the large new energy vehicle group achieved ROI in 12 months.

Their process director noted, “Jeenoce’s line transformed our production, making us a market leader.”

A leading supplier adopted the line for small-batch custom orders.

The automated assembly line met diverse demands, raising customer satisfaction to 95%.

Manual labor decreased by 70% (e.g., at station BS0011), cutting costs by 20% and shortening delivery times.

A global OEM enhanced its NEV production with our line. Magnetic levitation transport and optimized robot scheduling reduced energy use by 28%.

In 2024, it received a“Lighthouse Factory Best Practice”award from the China Association of Automobile Manufacturers.

These cases demonstrate Jeenoce’s ability to elevate efficiency and quality throughout the automotive supply chain.

The intelligent production line requires an initial investment but yields significant returns:

Clients typically recover their investment in 18-24 months. The large new energy vehicle group recouped its 36 million RMB in just 12 months, driven by a 35% throughput increase and 25% cost reduction. Lower defect rates saved over 2 million RMB yearly in scrap costs.

The modular design allows for future expansions, including interfaces for three more models, which helps reduce retrofit costs. Energy-efficient customized equipment, like magnetic levitation transport, reduces consumption by 40%, enhancing market competitiveness.

The line delivers 30-35% efficiency gains, 20-25% cost savings, and 10-15% quality improvements. The large new energy vehicle group’s daily output rose from 500 to 1,200 units, meeting their 35,000-unit monthly target.

Jeenoce provides comprehensive lifecycle support:

Our engineers oversee installation, calibration, and integration.

For the large new energy vehicle group, we fine-tuned robots for models A and B geometries and trained operators, completing deployment in three months.

24/7 remote support and regular maintenance ensure uptime.

The MES-integrated monitoring system predicts issues, reducing downtime from 4 hours to 8 minutes (e.g., at station BS0215).

With 127 standard automation units, the modular design allows rapid upgrades for new models or technologies at minimal cost.

The success of this production line hinges on the seamless integration of customized equipment and an automated assembly line.

Customized equipment, such as high-precision clamping systems and servo-driven coating guns, addresses the unique needs of side panel production.

These customized solutions allow for quick adjustments to the structural variations between models A and B, ensuring flexibility while maintaining accuracy.

Meanwhile, the automated assembly line ties these components together into a cohesive system.

By automating tasks like moving materials using AGVs and spotting defects with AR tech, we reduce human mistakes and speed up production times.

This synergy between customization and automation allows manufacturers to scale operations efficiently while maintaining quality, a critical advantage in today’s fast-paced market.

Beyond the large new energy vehicle group, this production line sets a blueprint for the future of automotive manufacturing.

As NEV adoption rises, manufacturers will need flexible, efficient systems to keep pace with innovation.

Our solution is designed to significantly lower energy consumption, which can lead to cost savings and environmental benefits.

Additionally, it improves the overall quality of products and services, ensuring that they meet high standards. Furthermore, it helps to reduce lead times, meaning that we can deliver products to customers faster.

This approach not only helps meet key global sustainability goals but also strengthens our capacity to compete successfully in the market.

By adopting such practices, we can demonstrate our commitment to environmentally friendly initiatives while simultaneously improving our overall standing among other businesses in our industry.

Focusing on both the environment and our organization's growth helps our planet and benefits us.

By prioritizing these areas, we stay relevant in a changing market. This approach also supports our success as we face future challenges and opportunities, helping us do well in business.

The recognition from industry bodies, such as the“Lighthouse Factory”award, underscores its potential to redefine manufacturing standards.

Jeenoce’s Flexible Side Panel Outer Plate Intelligent Production Line tackles multi-model production challenges with precision and innovation.

For the large new energy vehicle group, it boosted throughput by 35%, reduced defect rates to below 5%, and cut costs by 25%.

Peter Drucker famously said,“The greatest danger in times of turbulence is not the turbulence itself, but to act with yesterday’s logic.”

With two decades of expertise in custom automation, Jeenoce empowers clients to embrace the future of smart manufacturing.

Message