In the booming wave of new energy vehicles, the electric drive system serves as the "power heart" of the vehicle, directly determining the overall power, efficiency, and reliability.

Founded in 2010, GLB is an early entrant and technological leader in this core field. As a national high-tech enterprise specializing in high-performance electric motors and control equipment, GLB has gathered experienced professionals from home and abroad to build a full industrial chain covering product design, software development, product testing, and mass production.

GLB was jointly founded by a team of overseas returnee experts and a domestic listed company, perfectly combining international R&D vision with Chinese manufacturing expertise. This fusion has shaped its unique technological advantages and development path.

Leveraging extensive industry experience, the GLB R&D team has successfully developed AC motors, motor controllers, and power electronic devices characterized by the “Three Highs”: high performance, high efficiency, and high power density.

The company’s product technologies cover pure electric integrated drive systems, plug-in hybrid oil-cooled powertrain systems, and 48V mild hybrid systems, achieving performance levels comparable to leading international Tier 1 suppliers.

As of October 2025, GLB has received recognition and official designations from several top domestic automakers and began mass production in 2020.

In the field of electric drive technology for NEVs, GLB continues to lead the industry.

GLB’s product technologies span three major areas:

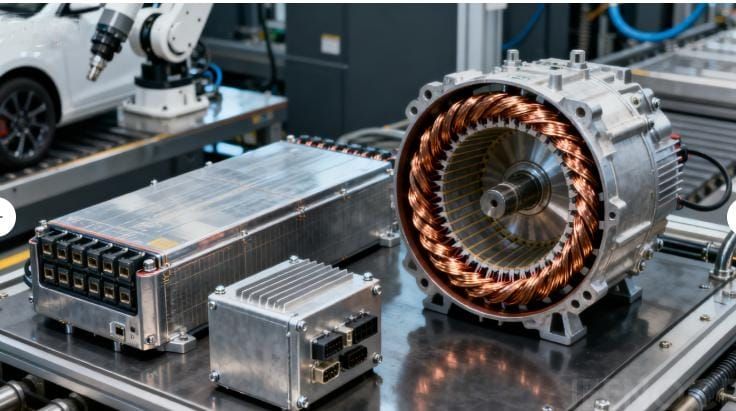

Pure electric integrated drive systems: Highly integrated key components to enhance efficiency and power density.

Plug-in hybrid oil-cooled powertrain systems: Optimized thermal management ensures stable operation under high load.

48V mild hybrid systems: Provide transition solutions for traditional fuel vehicles moving toward electrification.

In August 2025, the company’s “All-in-One Intelligent Power Drive System” was selected as one of the “2025 Excellent Cases of Automotive New Productivity-Driven Technologies.”

This system achieves unprecedented integration—combining permanent magnet synchronous motors, motor controllers, reducers, vehicle controllers, body control modules, onboard chargers, DC/DC converters, high-voltage distribution units, gateways, intelligent anti-slip control systems, and thermal management systems into one compact housing.

GLB’s technical strength in the core components of NEVs has been widely recognized by industry authorities.

Case Recognition: GLB’s “All-in-One Intelligent Power Drive System” was selected as a 2025 Excellent Case of Automotive New Productivity, demonstrating high recognition of its innovation.

Patents: The company holds 15 patented technologies, covering key processes such as motor production and inspection.

Quality Certification: GLB has obtained automotive industry quality management system certification, ensuring products meet international standards throughout their lifecycle.

Financing Progress: Completed Series D financing totaling 165 million RMB, highlighting strong market confidence in its growth.

Customer Success: GLB’s products have been successfully installed in Geely’s hit model “Starwish,” providing robust technical support for Geely’s expansion in the NEV market.

With the explosive global growth of the NEV market, electric drive systems are evolving toward high integration and intelligence. Traditional discrete architectures are being replaced by holistic solutions, and cost pressures are pushing enterprises toward more efficient and economical production methods.

GLB faces dual challenges:

Technical Challenge: How to further enhance system integration while ensuring inter-component synergy?

Production Challenge: How to simplify assembly processes, reduce line complexity, and cut manufacturing costs while maintaining quality?

To meet increasing market demand, GLB has established a Shanghai R&D center and production bases in Xuzhou, Jiangsu (annual capacity 800.000 sets) and Ningbo, Zhejiang (under construction, 500.000 sets). The company urgently needs solutions that ensure quality while greatly improving production efficiency.

During its search for solutions, GLB evaluated multiple domestic and international equipment suppliers and technology partners. After rigorous technical and capability assessments, GLB ultimately chose to partner with Jeenoce.

Three key reasons Jeenoce was selected:

End-to-End Service Capability: Providing full-process solutions to meet GLB’s needs from equipment to system integration.

Fast Response and Customization: Jeenoce demonstrated a deep understanding of GLB’s requirements and offered bespoke solutions aligned with future Industry 5.0 intelligent factory upgrades.

Optimal Cost-to-Performance Ratio: Jeenoce maintained technological leadership while offering a highly competitive cost advantage.

Joann Yang, GLB’s procurement director, commented:

“In our technical exchanges with Jeenoce, their professionalism and understanding of our needs were impressive. Their solution achieves the perfect balance between technological advancement and economic feasibility.”

To address GLB’s production needs, Jeenoce provided a complete intelligent production solution, incorporating Panasonic NPM-W2 placement machines, NPM-GP/L printers, and Rehm reflow soldering equipment to build a highly efficient, flexible, and traceable motor assembly line.

Key features include:

High-speed placement with visual positioning ensures accuracy, while intelligent material management reduces human error and ensures stable production rhythms.

Modular structure allows quick reconfiguration for multiple models, with standardized interfaces enabling rapid switching and increased uptime.

Multi-zone temperature control with nitrogen atmosphere regulation ensures welding consistency, oxidation prevention, and energy efficiency optimization.

Integrated with Panasonic’s PanaCIM platform, enabling real-time recording of process parameters, energy curves, and predictive quality analysis.

Enables full-process digital control from order to delivery, providing data-driven insights for production scheduling and quality decisions.

Barcode and RFID-based systems ensure every motor’s production history is traceable, meeting automotive zero-defect standards.

Jeenoce’s service team managed transportation, customs clearance, installation, debugging, and training, ensuring rapid commissioning and seamless mass production—helping GLB transition from smart equipment to a digital factory.

Production efficiency improved by 32.5%

Product yield reached 99.2%, leading industry standards

Automation significantly increased, achieving two-person per line operation

Overall Equipment Effectiveness (OEE) exceeded 85.6%

GLB’s technical director praised the collaboration:

“The Jeenoce team not only delivered advanced technical solutions but also deeply understood our project needs, providing comprehensive support throughout delivery.”

“Their quick response and professionalism allowed us to complete commissioning on a tight schedule, ensuring timely market launch.”

Following this successful cooperation, GLB has included Jeenoce as a long-term strategic partner, with plans to co-develop the next-generation electric drive platform for higher efficiency and lower cost integrated solutions.

GLB’s founder Dr. Guan Bo once said:

“We are committed to driving a smarter, safer, and cleaner world.”

Today, GLB Intelligent Power Technology Co., Ltd. is steadily advancing toward this vision—through continuous technological innovation, creating smarter, more efficient, and more reliable “electronic hearts” for new energy vehicles, leaving its mark on China’s and the world’s green automotive transformation.

Message