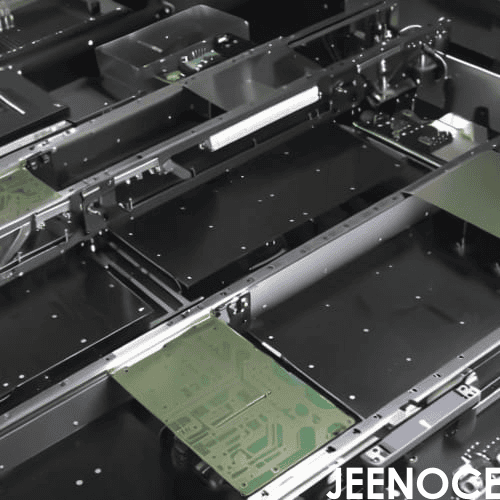

In the overall SMT process, the placement stage occurs after solder paste printing. Its main function is to accurately place surface-mount devices (SMDs) onto designated positions on the circuit board. The quality of placement largely determines the outcome of the subsequent soldering process and the final product. To ensure a high yield rate, Jeenoce integrates well-known machines into the complete SMT line, addressing key process challenges. This approach aims to maintain high production throughput while ensuring product quality, thereby helping customers secure more profitable orders.

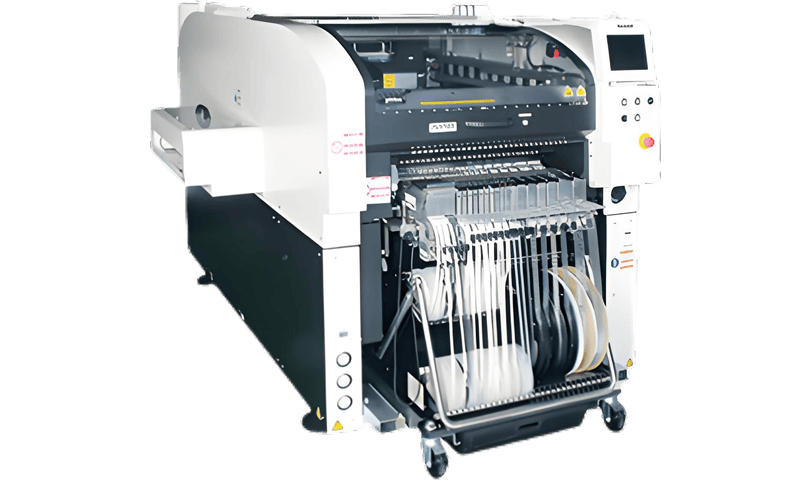

A placement machine is a compact automated system composed of a main control system (whose algorithms coordinate feeding, pickup, identification, and mounting) and various mechanical arms, suction nozzles, and other execution units. Using an intelligent vision system (CCD camera and image processing algorithms), it captures components and accurately places SMDs onto predefined locations on the PCB along a preset path.

The main purpose of the placement machine is to place the components accurately according to the fixed point, which is basically two parts:control and execution.

Control section

Visual recognition system: It compares images from the HD camera, quickly analyzes component positions, calculates offsets, and sends correction commands to the executing manipulator.

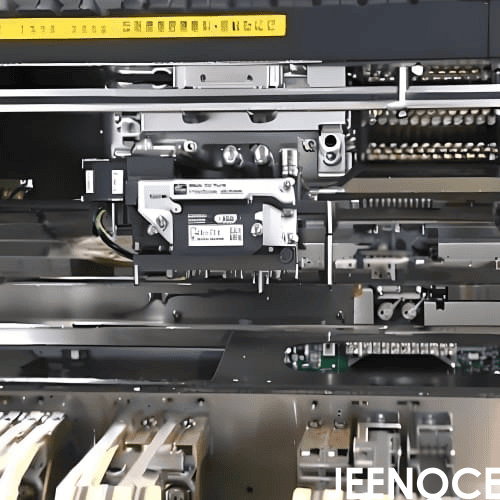

Main control system: preset procedures and steps to coordinate each component, set the mounting coordinates, sequence and other parameters, the system receives the information to automatically control the feeding, taking, identification and mounting, and realize the automation of the whole process.

Executable section

Servo robotic arm: Driven by a servo motor, it moves flexibly along the XYZ axes and delivers components along a preset path during operation.

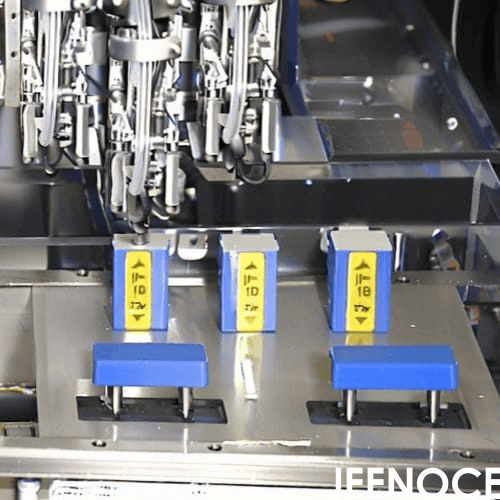

Nozzle: Can be replaced according to the size, type and shape of components. It can safely absorb components by making the air pressure inside the nozzle lower than the pressure difference of the external atmosphere.

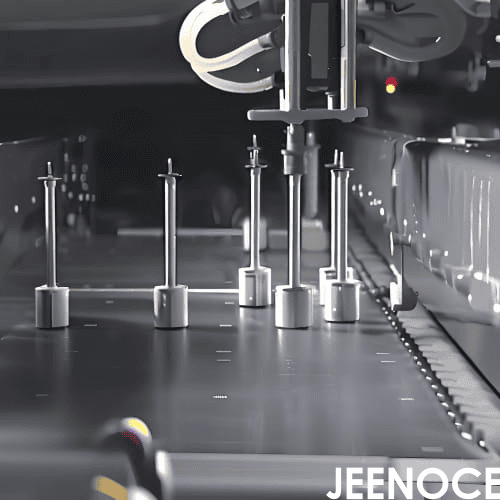

Workbench: Used to fix the PCB board, the workbench can move along the XY axis, with the mechanical arm to complete the mounting of the whole board.

Consumer electronics | Miniaturized components (e.g., 01005 capacitors), high-density circuit boards (HDI), high-speed placement accuracy (±25μm), such as Apple iPhones, computers, etc. |

Automotive electronics

| Automotive-grade reliability (-40°C to 125°C operating temperature), vibration-resistant design, zero defect rate (<10 DPPM), applied to ADAS systems. |

Medical Electronics

| Cleanroom environments (ISO Class 8 cleanroom), biocompatible materials, and micro-pitch component placement (<0.3mm), used in high-precision devices such as heart rate monitors |

Communications Electronics

| High-frequency materials (PTFE circuit boards), high-speed signal integrity, and multi-chip heterogeneous integration (SiP), applied in 5G base station modules |

Aerospace electronics

| Extreme environment tolerance (-55°C to150°C), radiation-hardened (RHBD), military standard certification (MIL-STD-883), suitable for radiation-hardened circuit boards, etc. |

Industrial electronics

| High durability (MTBF >100,000 hours), wide temperature range support, electromagnetic interference (EMI) design, suitable for industrial PLCs and sensor modules |

As a core equipment in electronic manufacturing, placement machines are used in nearly all fields involving circuit assembly. However, requirements vary by industry. Jeenoce’s placement machines focus on cutting-edge applications, delivering high-precision and high-reliability chip-level mounting.

Is it compatible with SMT whole line and multiple devices?

Since placement machines do not operate in isolation, they are often used alongside printers, solder paste inspectors, reflow ovens, or AOI equipment. With many brands available on the market, compatibility with various equipment is critical.

Does it have the production capacity to adapt to the entire SMT line?

The machine’s capacity must align with the production line’s throughput, and its placement accuracy should match the component types—especially for high-end sectors like semiconductor, automotive, and medical electronics.

Does it have flexible production capabilities?

The machine must support flexible production—such as quick changeovers and compatibility with multi-specification components—to adapt to evolving line requirements.

Does it support long-term operation?

To figure out how much the equipment will cost to maintain, how much power it will consume (say, less than 5 kWh per hour), and whether it can be upgraded in the future, the equipment integrator needs to ensure that the overall cost is controllable and cost-effective over the long term.

It stably handles 01005 micro components and high-density ICs, meeting precision requirements for HDI boards and SiP modules.

With micron-level precision and a very low defect rate, it ensures long-term reliability for automotive, medical, and aerospace products.

High-precision visual recognition and powerful master control algorithm cooperate to ensure that the effect of large quantities of PCB is unified and controllable.

The dual-track design achieves a mounting speed of up to 92,000 CPH, increasing production throughput by 25%.

It supports small-batch, high-mix production with quick changeover times under 30 minutes.

High-speed mounting supports large-scale production scenarios and directly brings about a leap in efficiency of the whole line.

It supports efficient SMT lines by seamlessly integrating with printers, reflow ovens, AOI, and other equipment, ensuring consistent product control.

The whole patch workflow from feeding to mounting and welding is automated to avoid errors caused by manual errors.

It integrates with MES systems to simplify production line management, trace issues, and guide upgrades for cost reduction and efficiency improvement.

Through modular design and intelligent control system to achieve multi-equipment collaborative operation suitable for large-scale electronic automation production line.

Support for mounting from 01005 micro components to 120x90mm large components.

Covering chips, capacitors, connectors and other types of products to easily meet the diversified needs of consumer electronics, automotive electronics and so on.

The large size (industrial control-CM402) and high-density circuit boards (aerospace electronics) can meet a variety of production scenarios.

Equipped with multiple types of nozzles and switchable mounting heads to seamlessly adapt to different component shapes and sizes.

Message