The automatic dispensing system is a set of integrated automatic equipment designed for accurately controlling the dispensing, coating, and potting of fluids (such as glue used in various SMT patch processing) on the surface or within the structure of electronic products.Jeenoce introduced this system, leveraging 60 years of experience from the original U.S. factory, with the goal of improving production efficiency, reducing manual errors, lowering glue consumption, and ensuring product quality for our customers in industries such as automotive, aerospace, medical, pharmaceutical, and high-end electronics manufacturing.

To address the transition from military laboratory to mass production, Jeenoce introduces a complete SMT line solution for the automatic dispensing system, offering the following three modes:

S-LINE: It is mainly for small production scenarios with limited space, such as laboratories and other usage scenarios.

R-LINE: Design solutions for medium scale electronics production with partial flexibility and certain production capacity.

C-LINE: Specially designed for large-scale electronic production lines equipped with digital intelligence capabilities and mass volume production capabilities.

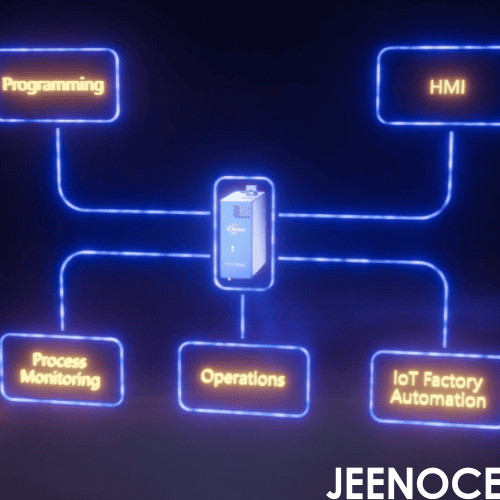

A well-designed automatic dispensing system should balance considerations such as dispensing accuracy, flexible configuration, automation, detection settings, operational safety, human-computer interaction, personalized design, durability, and cost control.

Dispensing Accuracy:the ability to accurately control the amount of fluid droplets, position and coating thickness, including errors, is the key to determine whether the product is reliable!

Flexible Configuration:that is, modular design,whether it can flexibly adjust the combination of coating,curing and testing modules according to different production needs,and adapt to the dispensing system of various scales and different processes.

Additionally, if the current customer demand is for small-scale production, and there may be a need to upgrade the automatic dispensing system in the next phase, can it support such an upgrade?The customer wants to turn the factory into an intelligent factory、control production data,whether can it be transmitted?

Automation Level: High automation improves both output and yield, and also influences production capacity in various ways.

Inspection Setup:Equipped with visual detection module,and real-time monitoring of coating coverage and bubble、fracture and other defects, in the production to solve the problem to reduce the rework rate.

Operational Safety:Does the entire system comply with environmental regulations? Whether a residue exhaust gas collection system is designed to ensure personal safety and the life of the equipment when dealing with volatile compounds and different materials.

Human-Machine Interaction:Is the HMI setup simple?Support for external excuses( such as MES system),on the one hand,and can reduce the difficulty of using to avoid operational errors, on the other hand, can reduce training costs.

Customization design:Can the design be optimized according to the actual situation of the current customer,such as dispensing system in a narrow space or customized design in a narrow space.

Durability:such as dispensing nozzle、positioning probe and other long time high strength use of parts quality pass,after all,for large SMT patch production line,and downtime for a day is hundreds of thousands to millions of economic losses.

Cost Control:Lean management is one of the core concepts that Jeenoce can run through all solutions.Our non-standard automation solutions are designed in strict accordance with the principle of taking the interests of customers as the first. Therefore, whether we can achieve more powerful capabilities for customers within a reasonable cost space is something that every solution integrator should consider.

From the production process,and the automation replacement is an unstoppable trend, manual because of a variety of objective and physiological reasons will always lead to a variety of problems,as the execution unit,first of all,whether the execution ability can be achieved,whether the accuracy is in place is an unstandardized problem.

In terms of the quality of the products produced, there are great errors in human visual identification and visual operation.If it is a simple product,such as sports headphones and the circuit board of a calculator,which can be satisfied,but as long as it involves the core components of automobiles、military industry、aerospace、medical medicine and other human lives,whose simple short circuit problems may bring immeasurable consequences and losses.

Overall production efficiency and productivity improvements are largely determined by how effectively humans use tools. From the steam engine in the second industrial revolution to the modern use of sensors and control modules, these innovations have led to exponential productivity growth.

Therefore, the automated dispensing system is the final solution for the dispensing process in the current scientific and technological means.

The automatic dispensing system introduced by Jeenoce from the original factory in the United States is precisely a series of European and American industrial standards of various module combination scheme configuration,and the main purpose is to customize to solve the various needs of customers in order to customize the problem.

Module Type | Key Features | Suitable for Industries and Applications |

Core Coating Module | The module uses precision spraying to deliver uniform coatings, enabling accurate dispensing of adhesives with varying viscosities | PCB products for SMT assembly, automotive electronics, medical electronics, semiconductor packaging, and LED manufacturing |

Curing Module | Top and bottom material curing processes prevent issues like coating migration, pinholes, solvent residue, and bubbles | Medium to high-volume production lines (mid-to-high-end electronics) |

Removes solvents and bubbles from coatings to enhance coating quality | Compatible with S-LINE compact production lines | |

Inspection Module | Real-time detection of coating uniformity, supporting SMT/THT applications | High-quality PCB assembly and semiconductor packaging |

Inspects coating results after flash-off or curing | Compatible with S-LINE compact production lines | |

Integrated IR curing function for manual coating quality inspection | Suitable for low-volume or customized production lines | |

Panel Processing Module | Reversible PCB handling for products requiring double-sided coating | PCBs requiring double-sided coating, SMT assemblies |

Customizable modules for specific coating or inspection requirements | Custom solutions for complex boards or specialized coating needs | |

Automated loading/unloading process management Residue cleanup (e.g., exhaust fumes, residue) | Suitable for C-LINE high-capacity production environments | |

Auxiliary Module | Residue cleanup (e.g., exhaust fumes, residue) | Production environments with safety standard requirements (generally applicable) |

Dynamic probe height adjustment for balanced detection across varying dispensing heights | High-precision dispensing scenarios like semiconductor packaging and microelectronics | |

Software and Control Module | High-precision flow control with automatic viscosity compensation ensures coating consistency (NPI Award Winner) | High-precision coating production lines |

Centralized process control and data management supporting Industry 4.0 traceability requirements | Highly automated, data-driven production lines |

The above is the configuration module of part of the automatic dispensing system,and Jeenoce and hundreds of engineers from Nordson original factory in the United States are constantly developing breakthrough and updated technology,including making new adjustments to respond to customer feedback.

For more detailed specifications or customized configurations,and please contact the Jeenoce technical team directly for the latest technical documentation or customized solutions.

Dispensing as a crucial link in the SMT process,in fact,all products in the electronic industry need this process, but considering the cost performance and different requirements and standards.

The dispensing system introduced by Jeenoce is more suitable for those with a certain scale and certain requirements for accuracy and technology,such as military electronics、automotive electronics、avionics、medical electronics、new energy and other electronic processing industries.

Nordson American has more than 60 years of experience in the design and production of automated dispensing systems

Ability and strength to implement customer ideas and ideas

More than 35 national experts stationed offices are ready to respond to your needs

Focus on analyzing problem iterative techniques through feedback from global customers

Meet the complex process production scenarios from compact smt production lines to mass automation

Support all kinds of spraying methods、spraying substrate materials、glue viscosity treatment

The reserved intelligent interface can upgrade the intelligent production mode at any time

Modular assembly allows customers to achieve their desired goals within a limited budget

High-precision dispensing ensures that the coating remains highly consistent

Fully automated production maximizes production efficiency

The real-time detection module directly solves production defects and defective products in the production process

Compatible with industry 5.0 intelligent manufacturing standard second digital factory

Message