Jeenoce reflow ovens deliver unmatched uniformity, efficiency, and scalability to optimize your surface mount technology (SMT) production. Designed for precision and reliability, these ovens ensure consistent solder joints across a broad range of PCB types and sizes, reducing defect rates and improving yield.

Key Advantages

| Feature | Benefit |

|---|---|

| Uniform Temperature Control | Guarantees even heat distribution for consistent soldering results |

| Advanced Reflow Profile Setup | Supports precise adjustments, including lead-free reflow profiles, to meet diverse PCB requirements |

| Energy-Efficient Design | Lowers operational costs while maintaining optimal thermal performance |

| Scalable Throughput Options | Flexible for small batch production or high-volume lines without sacrificing quality |

| Multi-Zone Heating System | Allows fine-tuned control over each reflow stage for maximum process stability |

Ideal for High-Mix Low-Volume to High-Throughput Production

Whether your line handles frequent product changes or mass manufacturing runs, Jeenoce ovens adapt seamlessly. Their modular design combined with intuitive controls supports:

Rapid product changeovers with minimal downtime

Consistent quality across varied PCB designs

Integration with nitrogen reflow soldering systems for lead-free and special applications

Choosing Jeenoce reflow soldering machines means investing in a proven industrial SMT soldering tunnel that balances precision, flexibility, and long-term ROI for today’s fast-evolving smart manufacturing environments.

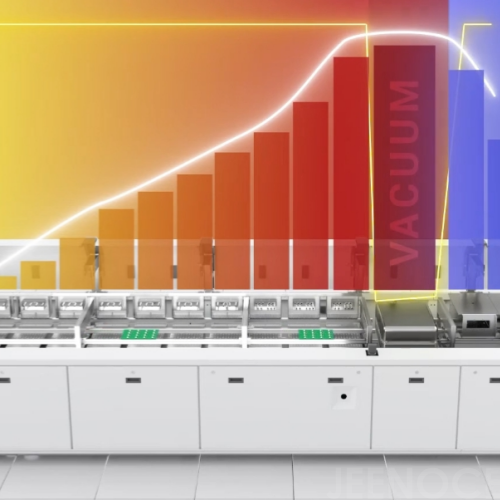

Reflow soldering is the heart of the SMT assembly process, turning solder paste into strong electrical and mechanical connections on your PCBs. Here’s how it works in simple steps:

Preheating: The board gently warms up to avoid thermal shock and prepare the solder paste for melting.

Soaking: Temperature stabilizes to activate flux and reduce oxidation.

Reflow: Heat peaks, melting the solder to bond components firmly.

Cooling: The board cools gradually, solidifying the solder joints.

This four-stage thermal profile is crucial to avoid defects and ensure reliable connections.

Lead-Free vs Leaded Profiles

With environmental rules tightening, lead-free solder profiles are more common in the U.S. They require slightly higher and longer peak temperatures compared to traditional leaded profiles. Jeenoce smartly adapts to these differences with precise temperature controls, ensuring perfect results whether you’re running lead-free or leaded soldering processes.

Jeenoce Adaptive Controls

Jeenoce’s reflow ovens feature intelligent controls that monitor and adjust the thermal profile in real-time. This means consistent heat distribution even for mixed batches, preventing cold joints or overheating. Their adaptive system is great for managing different solder types, complex PCB designs, and varying throughput needs while keeping quality top-notch.

Jeenoce Reflow Soldering Ovens are designed to meet the demanding needs of industrial SMT lines in the United States. Built for consistent performance, these ovens handle high volumes without compromising on quality or uptime.

Key Technical Features

| Feature | Description |

|---|---|

| Temperature Zones | Multi-zone heating for precise reflow control |

| Maximum Conveyor Speed | Up to 1500 mm/min for fast throughput |

| Temperature Range | 50°C to 300°C, supporting lead-free and leaded profiles |

| Heating Method | Convection and infrared options available |

| PCB Size Capacity | Supports boards from 50mm x 50mm up to 510mm x 460mm |

| Nitrogen Injection System | Optional for oxidation-free lead-free soldering |

| Control System | Adaptive digital controllers with real-time feedback |

| IoT Monitoring | Available for remote status, alerts, and data logging |

Customization Options From Nitrogen Injection to IoT Monitoring

We understand manufacturers often require tailored solutions. That’s why Jeenoce offers:

Nitrogen Reflow Soldering System: Reduces oxidation and improves solder joint quality, essential for lead-free reflow profiles.

IoT Integration: Connect ovens to your factory network for live monitoring, predictive maintenance, and historical data access.

Flexible Zone Settings: Adjust heating zones independently to fit your unique PCB designs or new solder types.

Batch or Inline Configurations: Choose between batch reflow soldering equipment for smaller runs or continuous multi-zone reflow ovens for high throughput.

Energy-Efficient Components: Save on power consumption with optimized heaters and smart temperature control.

With these specs and options, Jeenoce reflow ovens offer reliability and flexibility tailored for SMT production environments.

Jeenoce reflow soldering ovens are designed to fit perfectly into your existing SMT line. Whether you use pick-and-place machines, automated inspection stations, or advanced conveyor systems, our ovens work smoothly alongside all of them. This seamless compatibility means less downtime, fewer adjustments, and a more streamlined production flow.

Compatible with Pick-and-Place Inspection and Conveyor Systems

Our reflow ovens sync effortlessly with popular pick-and-place equipment, ensuring precise timing and accurate placement before soldering. They also integrate with inspection systems, helping catch defects right after soldering, which boosts overall quality control. Plus, the ovens coordinate with conveyor lines, supporting continuous, high-speed manufacturing without bottlenecks.

Real-World Applications in Smart Manufacturing

Many U.S.-based manufacturers already trust Jeenoce for their smart factories. Our industrial SMT soldering tunnels and convection reflow ovens optimize throughput while maintaining tight control over temperature profiles – critical for consistent results in lead-free and leaded solder processes. Whether you run small batch reflow soldering equipment or high-volume PCB soldering furnace setups, Jeenoce helps you automate smarter, reduce waste, and improve product reliability.

Keeping your Jeenoce reflow soldering oven running smoothly means regular upkeep and smart operation. Here’s how to stay on top of maintenance while keeping safety and efficiency front and center.

Daily Profiling Best Practices

Run daily thermal profiles to verify consistent reflow temperatures on your PCBs. This helps catch any shifts early before product quality is affected.

Use Jeenoce’s adaptive controls to fine-tune settings, ensuring your lead-free or leaded reflow profiles hit the right temperature curve every time.

Inspect conveyor belts and zone heating elements daily to prevent downtime caused by wear or malfunction.

Safety Tips for Reflow Oven Maintenance

Always power down the oven and unplug before performing any cleaning or maintenance tasks.

Use personal protective equipment (PPE) like heat-resistant gloves and safety glasses, especially when dealing with hot surfaces or nitrogen injection systems.

Follow Jeenoce’s manufacturer guidelines strictly to avoid accidents during maintenance or troubleshooting.

Energy-Efficient Design for Sustainable Operations

Jeenoce’s reflow ovens are built with energy-saving features that reduce power consumption without compromising performance:

Multi-zone temperature control lets you apply heat only where needed, lowering overall energy use.

Insulated chambers minimize heat loss for better thermal efficiency.

Optional nitrogen reflow soldering systems not only improve solder quality but reduce oxidation and can save energy by optimizing gas usage.

By following these maintenance and safety tips along with regular profiling, you’ll keep your SMT reflow oven reliable and cost-effective, supporting a greener, more sustainable manufacturing process.

What is a reflow soldering oven?

A reflow soldering oven is a machine used in the SMT process to melt solder paste and join electronic components to PCBs. It heats the board through controlled temperature zones to ensure reliable solder joints.

How does Jeenoce’s convection reflow soldering machine improve production?

Jeenoce ovens provide uniform heat distribution, precise reflow temperature control, and customizable profiles, making them ideal for both lead-free and leaded soldering. This boosts efficiency and product quality.

Can Jeenoce reflow ovens handle different production volumes?

Yes, they’re scalable for high-mix low-volume runs and can also manage high-throughput production lines, adapting to your business needs.

What is the difference between lead-free and leaded reflow profiles?

Lead-free profiles require higher peak temperatures and longer dwell times. Jeenoce’s adaptive controls allow quick profile changes to suit either type, ensuring optimal soldering results.

Do you offer customization for reflow ovens?

Yes, options include nitrogen reflow soldering systems, multi-zone temperature control, and IoT monitoring for real-time data, helping improve your process control and quality.

How do I maintain the reflow oven for best performance?

Daily profiling, regular cleaning, and timely calibration keep the oven working efficiently. Jeenoce ovens include energy-efficient designs, which help reduce operational costs.

Is Jeenoce compatible with other SMT equipment?

Absolutely. Our reflow ovens integrate seamlessly with pick-and-place machines, inspection systems, and conveyor setups, creating a smooth production flow.

What safety features are included?

Our ovens come with multiple safety measures like automatic shutdowns, over-temperature protection, and easy access for maintenance to keep your team safe.

If you’re looking to boost your SMT line’s efficiency and quality, investing in a Jeenoce reflow soldering oven is a smart move. Our ovens deliver consistent reflow temperature control and reliable solder reflow machine performance, whether you’re running a high-mix low-volume setup or a high-throughput production line.

You’ll benefit from features like multi-zone convection reflow soldering, adaptable lead-free reflow profiles, and seamless integration with your existing PCB soldering furnace and automation systems. Plus, options like nitrogen reflow soldering systems and IoT monitoring make it easy to stay ahead in today’s competitive market.

Upgrading to a Jeenoce SMT reflow oven means less downtime, better solder joints, and smoother production. Ready to make the switch? Contact us today to find the right convection reflow soldering machine built for your industrial SMT soldering tunnel needs.

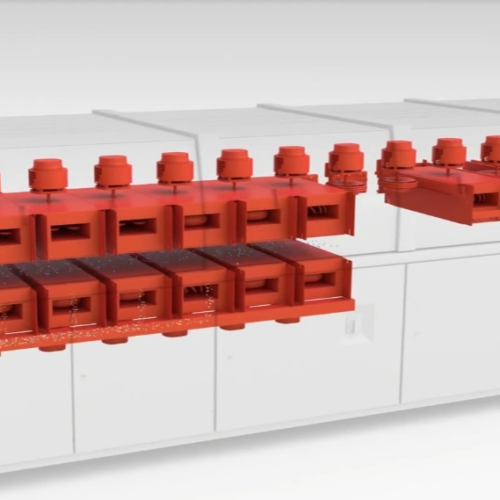

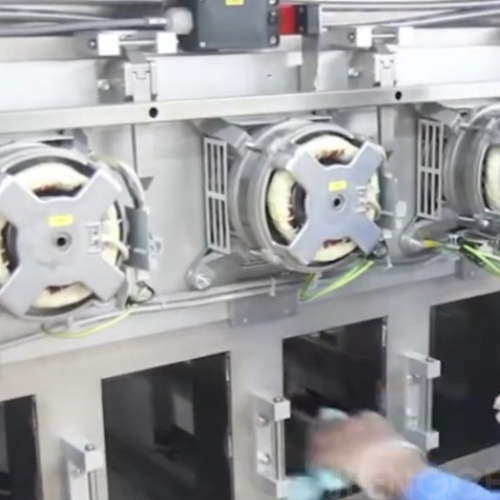

Jeenoce's reflow soldering system enables individual fan frequency adjustment for each temperature zone via special customized nozzles, realizing precise control.

Its special rectifier plate ensures uniform hot air distribution on the PCB board to achieve optimal heat conduction.

A rigorous heat insulation scheme helps the system match the optimal temperature curve with product parameters like size and material.

This highly product-adapted process ultimately produces excellent products.

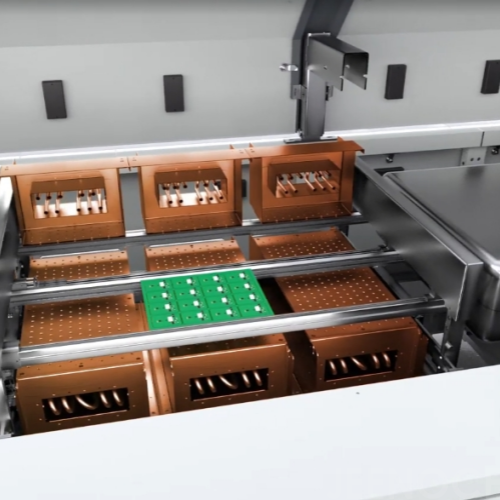

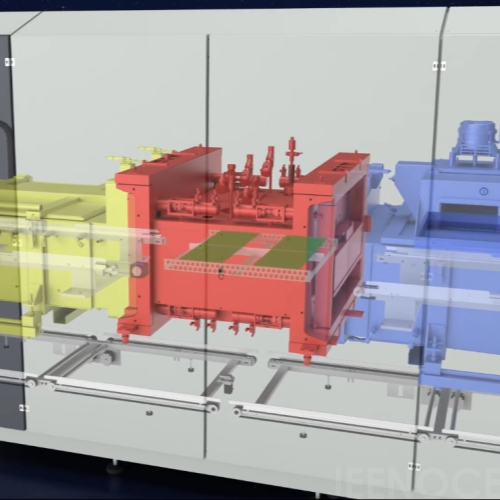

Jeenoce's reflow soldering system can accurately adjust key parameters (number of temperature zones, residence time length) and modify the transmission system based on different needs.

These adjustments cover scenarios like matching temperature zone process length, temperature curve speed, and adapting to the number or size of products being produced simultaneously.

The system supports both simultaneous production of multiple products and processing of larger-sized products.

Its flexible welding module design provides customers with more options.

This flexibility ultimately delivers higher cost performance for customers.

The Jeenoce reflow soldering system maintains low energy consumption during non-working periods.

It keeps equipment active with the minimum energy required when not in production.

The system can directly resume production status when needed.

Compared with shutdown and restart, it consumes fewer resources over the entire production cycle.

This mode also makes the overall production cycle more efficient.

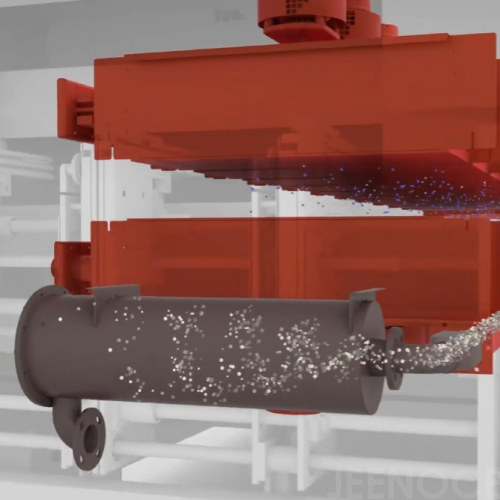

The Jeenoce reflow soldering equipment is equipped with a residue waste recovery system designed by German engineers.

This system maximizes the collection, treatment and secondary utilization of waste.

The equipment features very low carbon dioxide emissions and minimal nitrogen waste.

It also delivers an external effect of clean and simple internal furnace cavity.

Thanks to its powerful recycling system, maintaining the Jeenoce reflow soldering equipment’s basic cavity only requires regular replacement of the waste collection device.

Unlike similar products, the equipment’s transmission system is placed outside the furnace.

This external placement saves significant manpower and material resources.

It also exempts the transmission system from the impact of high temperature and residue.

As a result, the transmission system has a longer service life.

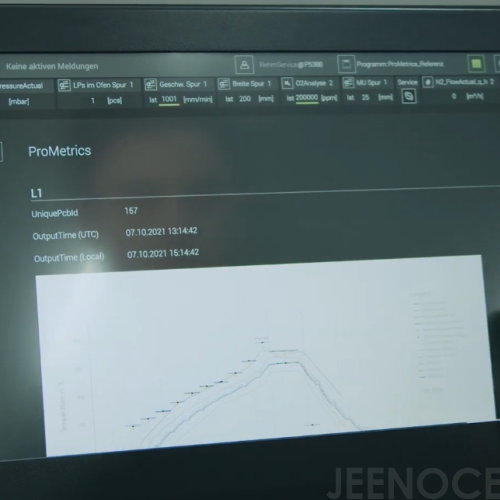

The Jeenoce system generates corresponding data files for each component in the welding process.

Scanning the barcode, transmission or directory on a component enables dynamic tracking of the entire welding process flow.

When issues arise, results can be compared with database files.

This comparison allows quick problem identification.

The process avoids disrupting ongoing production.

Jeenoce reflow soldering system targets the welding of large PCB circuit boards.

It is equipped with a specially added central support module.

This module prevents product deformation caused by uneven stress during welding (when the product is affected by heat).

Ultimately, it solves the stress tearing issue in the welding of large-sized products.

Three-stage energy-saving mode is not fixed; it intelligently adjusts energy consumption in heating, insulation, and cooling links based on different production scenarios and process requirements.

This adjustment saves significant energy while ensuring the welding effect.

The reflow soldering system includes a "electric shutter door" module designed by German engineers (a well-known industry design).

This single module reduces nitrogen consumption by 20%.

Overall, the system achieves up to 60% energy saving, 40% nitrogen saving, and 50% cooling water saving.

Message