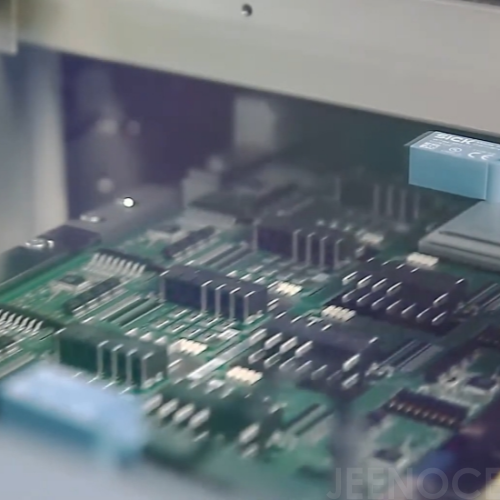

Vacuum reflow soldering stands out as the leading solution for high-reliability electronics manufacturing. It dramatically reduces voids in solder joints, ensuring stronger connections and better thermal and electrical performance. At Jeenoce, our vacuum reflow soldering systems combine advanced technology with user-friendly design, delivering consistent quality for demanding applications.

Core Benefits of Jeenoce Vacuum Reflow Soldering

| Benefit | Description |

|---|---|

| Superior Void Control | Removes air bubbles during soldering to create void-free joints, improving reliability. |

| Process Flexibility | Supports fluxless, eutectic, and lead-free soldering processes adaptable to various boards. |

| Production Efficiency | High throughput with quick ramp rates and precise temperature control reduces cycle times. |

| Sustainability Focus | Optimized nitrogen consumption and energy-efficient heating minimize environmental impact. |

| Easy Integration | Compact footprint and versatile conveyor options fit seamlessly into existing SMT lines. |

Heating and Vacuum System

Our vacuum reflow soldering machine is designed for precise temperature control and vacuum management to ensure low void soldering and high-reliability reflow soldering results.

| Feature | Specification |

|---|---|

| Heating Zones | 6 zones (Preheat, Soak, Reflow, Cooling) |

| Vacuum Range | 100mbar- 10mbar |

| Max Temperature | 500°C |

| Heating Type | Convection with optional fluxless vacuum reflow |

Conveyor and Handling

Efficient board handling is key for inline reflow soldering systems, and our vacuum reflow oven supports different setups for SMT lines with versatility.

| Feature | Specification |

|---|---|

| Conveyor Type | Mesh belt or Pin-chain options |

| Board Width | 3150mm- 4900mm |

| Conveyor Speed | Adjustable 0–1500 mm/min |

| Staging Conveyor | Integrated for smooth entry and exit |

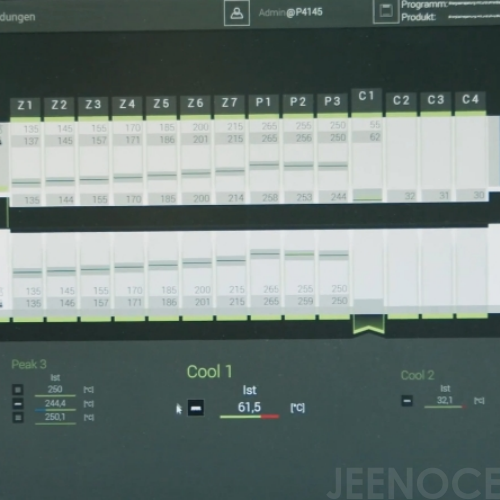

Control and Monitoring

Our reflow soldering system comes with smart controls and monitoring tools for real-time profiling and operational safety.

PLC with user-friendly HMI interface

Real-time temperature and vacuum profile display

Gas Options: Nitrogen vacuum reflow or air reflow operations using Galden®

Safety features include automatic shutdown on vacuum loss and over-temperature

Our vacuum reflow soldering system is built to meet the demands of various industries, delivering reliable, low-void solder joints every time.

Automotive Electronics:

Ideal for advanced driver-assistance systems (ADAS) and battery management modules, where high-reliability soldering is crucial to withstand harsh driving conditions.

Power Semiconductors:

Perfect for IGBT and DBC substrates used in electric vehicle (EV) inverters, ensuring strong, void-free connections that handle high power and temperature.

Consumer and Telecom:

Used extensively in 5G modules and wearable devices, offering precise control and fluxless vacuum reflow options to maximize performance in compact electronics.

Aerospace and Medical:

Supports hermetic sealing processes, essential for aerospace and medical devices that require airtight, high-reliability packaging to survive tough environments.

With this versatility, our vacuum reflow soldering equipment is a go-to solution in global manufacturing for achieving consistent quality and production efficiency.

Preheat Zone: Gradual Heating and Flux Activation

In the preheat zone, the vacuum reflow soldering system gently raises the board temperature. This step activates the flux, preparing the solder paste without shocking the components. It’s all about getting the board ready for a smooth, reliable soldering process.

Soak and Reflow: Convection Heating with Fluxless Option

Next, the system moves into the soak and reflow phases. Here, convection heating evenly melts the solder for strong joints. There’s also a fluxless option for specific applications, reducing residue and improving cleanliness, especially in high-reliability setups.

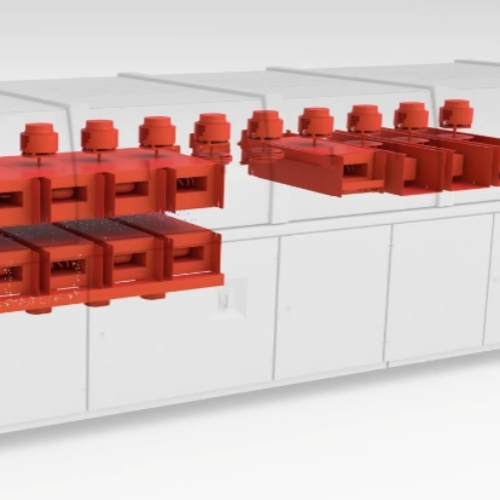

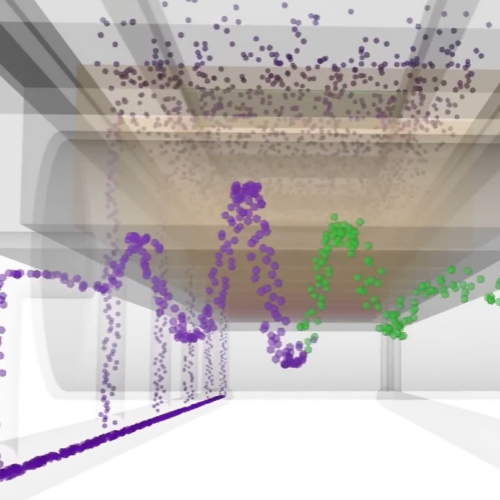

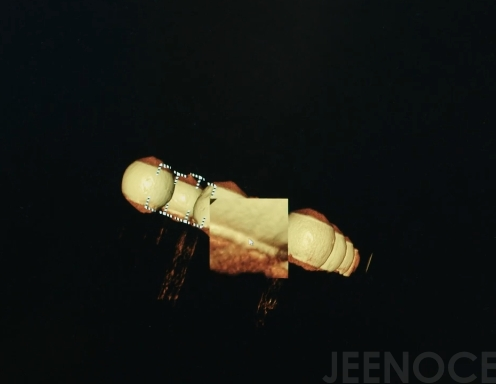

Vacuum Application: Chamber Seal and Void Extraction

Once the solder melts, the vacuum chamber seals tightly. This step actively removes trapped air, dramatically reducing voids and preventing weak points in the solder joints. It’s key to ensuring superior quality, especially for sensitive and power electronics.

Cooling Zone: Forced Air or Nitrogen Cooling

After reflow, the boards move into the cooling zone. Controlled cool-down is done using forced air or nitrogen (N2) to avoid thermal shock and maintain joint integrity. Nitrogen also helps prevent oxidation during cooling.

Exit and Inspection: Inline Data Export for Quality Analytics

Finally, the system exports real-time data for inline quality inspection. This helps operators track soldering performance instantly and make quick adjustments, boosting yield and reliability across production runs.

Case Studies: EV Module Void Defect Reduction

Many of our customers in the electric vehicle (EV) sector have seen a dramatic drop in void defects after switching to our vacuum reflow soldering system. By eliminating air pockets during the soldering process, the reliability and performance of power modules have significantly improved. This leads to longer-lasting EV components and fewer recalls.

Testimonials: Integration and Support

Clients appreciate how easily our SMT vacuum soldering machine integrates into existing production lines. From the initial setup to ongoing support, the Jeenoce team is known for responsive service and practical guidance, helping manufacturers maintain smooth, efficient operations with minimal downtime.

Metrics Highlight: ROI and Yield Improvement

Return on Investment (ROI): Many users report a quick payback period thanks to lower scrap rates and higher throughput.

Yield Improvement: The vacuum reflow system consistently delivers higher first-pass yields by reducing voids and defects, especially in sensitive applications like automotive ADAS sensors and power semiconductors.

Our vacuum reflow soldering equipment is designed not just for today’s production needs but also to support future advancements with reliable, low-void, high-reliability solder joints.

| Question | Answer |

|---|---|

| Standard vs Vacuum Reflow? | Vacuum reflow removes air during soldering, reducing voids and improving joint quality compared to standard ovens. |

| Can it do fluxless soldering? | Yes, the system supports fluxless vacuum reflow, ideal for sensitive applications and clean joints. |

| What board sizes are supported? | Typically fits small to large PCBs; adjustable conveyor options handle various widths and thicknesses. |

| Why choose vacuum for reliability? | Vacuum reflow ensures strong, void-free solder joints, crucial for high-reliability sectors like automotive and aerospace. |

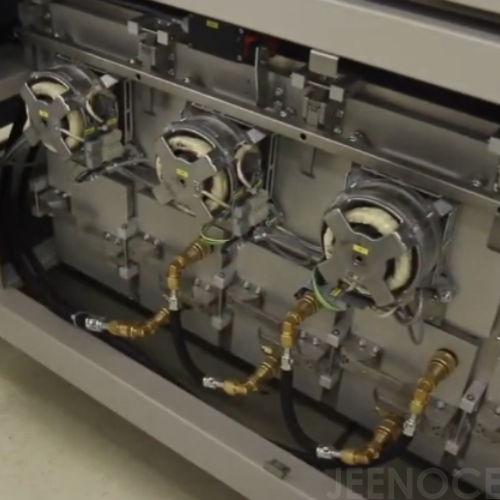

| How to maintain the vacuum module? | Regular filter cleaning, leak checks, and pump maintenance keep the vacuum system running smoothly. |

| Nitrogen vs air operation? | Nitrogen enhances soldering by preventing oxidation and aids void reduction, though air operation is possible with some trade-offs. |

This quick FAQ covers key points to help you understand why vacuum reflow soldering stands out and how it fits your production line needs.

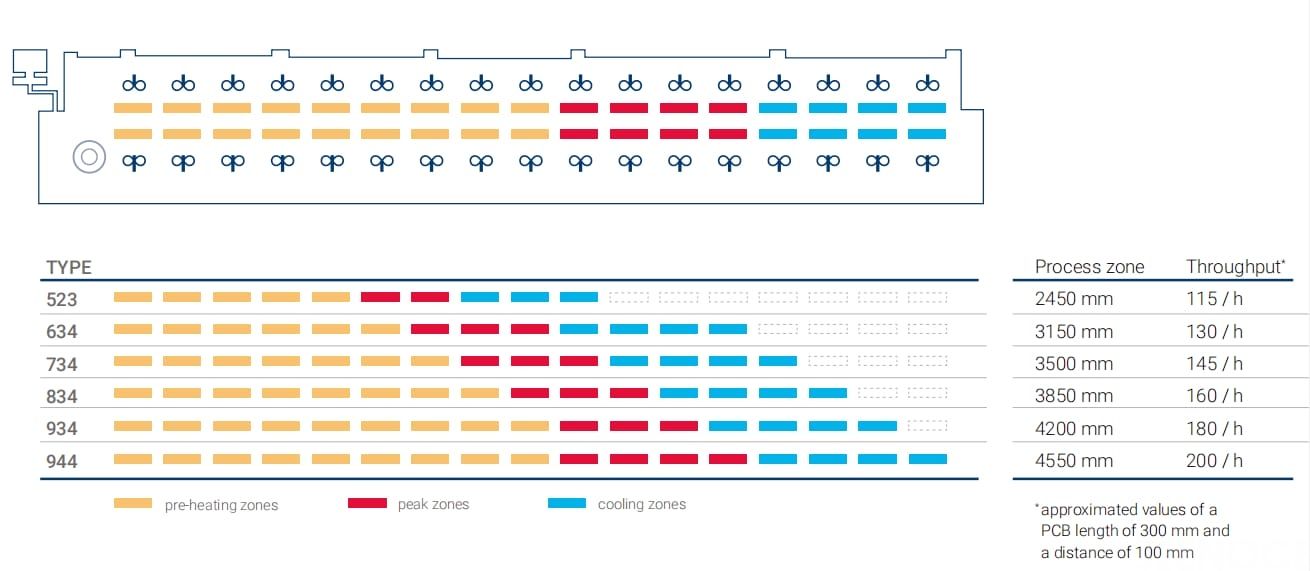

The system supports adjustment of the number and layout of heating zones to meet the requirements of different soldering processes.

The design of conveyor belt support circuit boards of different sizes,ranging from small prototypes to large production line.

Adjust temperate cure according to different types of welding materials and components types to ensure soldering quality and efficiency.

The system adopts modular design to facilitates changes, upgrades or modifications, and extends the device life cycle.

Rducing rework and scraping costs and increase of production efficiency by precise technology control.

Decrease of electrical energy consumption and lower operating costs by the efficient heating and cooling system.

Some decrease of maintenance frequency and cost with firm structure of devices and the small number of movable components.

Ensure long-term and stable usage life of devices with reliable materials to extend its service life.

The vacuum environment can diminish pollution of oxidation, volatile emissions and carbon emissions to nature.

Comply with international environment protection regulations and supporting enterprises in achieving sustainable development.

Decreasing remains after soldering and the demand for chemical cleanser to further decreasing environment impact.

The unique sleeping setting can allow reflow oven to resume production instantly.

The stable low-energy consumption operation state saves a lot of time.

Significant savings in energy consumption and cost expenditure.

The device components can be replaced independently to simplify maintenance process and reduce downtime.

Open design is convenient for inspection and cleaning, reducing maintenance difficulty.

Maintenance process does not require complex tools or professional training, reducing labor cost.

Supporting precise temperature distribution control in multiple heating zones to ensure the uniformity of soldering.

The closed-loop control system can accurately adjust vacuum degree to optimize the welding conditions.

Adjusting transmission speed according to types of circuit boards to ensure process stability.

Supporting multiple process recipes for convenient and rapid switching of production tasks.

Providing functions of data recording and real-time monitoring, and supporting process optimization and quality traceability.

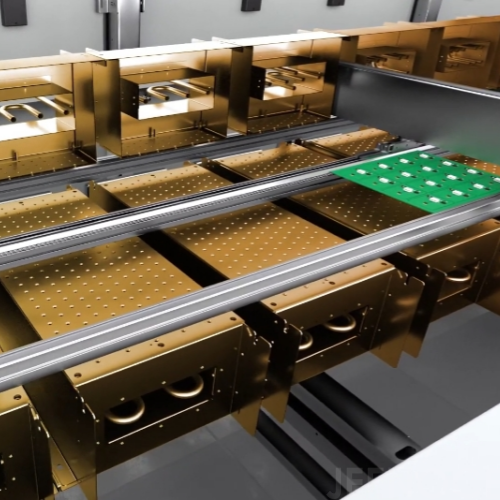

The design of central support can effectively prevent circuit board from deforming or moving during the soldering process.

Suitable for rather large or heavy circuit boards, meeting diverse production requirements.

Reducing the problems of solder bridges or open circuits caused by movement of the circuit boards to ensure high-quality welding joints.

Reducing or eliminating the need for flux to lower the residues on the circuit boards.

Effectively removing smog and particles to reduce the accumulation inside the equipment.

The design of the equipment reduces cleaning need and extends maintenance cycles.

The vacuum environment can completely eliminate soldering voids to enhances connection reliability.

High-quality welding points can extend production usage life and reduce the failure rate.

Meeting the strict requirements of the high-reliability industries such as aerospace, automotive electronics, military and so on.

Message