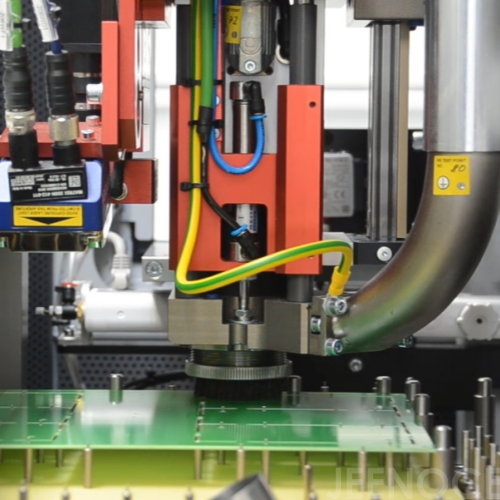

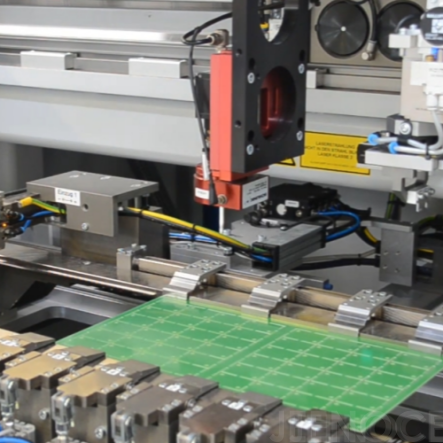

Meet the Jeenoce PCB Depaneling Machine — your ultimate solution for fast, accurate, and stress-free PCB singulation. Designed specifically for high-volume Surface Mount Technology (SMT) production lines, this advanced milling and sawing system delivers flawless separation of FR4 boards and complex PCB panels every time.

Key Benefits at a Glance:

Integrated milling & sawing for versatile depaneling needs

Servo-controlled precision ensuring clean edges and zero damage

High throughput suitable for mass production environments

Compact footprint and user-friendly touchscreen controls

Looking to cut down on manual labor and boost your factory’s efficiency? The Jeenoce PCB depaneling machine is engineered to fit seamlessly into your SMT line, providing consistent, reliable singulation speed that scales with your business.

Ready to transform your PCB depaneling process?

Jeenoce stands out as a leader in PCB singulation equipment, offering an integrated milling and sawing PCB depaneling machine designed for precision and speed. Our solution fits perfectly into high-volume SMT production lines, ensuring smooth, stress-free PCB divider operations.

Core Features and Innovations

| Feature | Benefit |

|---|---|

| Servo-Controlled Movement | Ultra-precise positioning for clean, accurate cuts |

| Dust Extraction System | Keeps workspace clean, improving safety and machine life |

| Programmable Touchscreen | Easy-to-use interface for fast programming and adjustments |

| Modular Design | Allows flexible upgrades and quick maintenance |

These elements combine to create a robust milling router depaneler that handles a wide range of FR4 board depaneling tasks with minimal stress on the PCB. Our built-in dust extraction keeps your work environment clean, while the servo-controlled precision reduces defects and rework – a must-have for any automated PCB panelizer.

Jeenoce’s PCB depaneling machine supports various cutting requirements, including milling, sawing, and tab routing. The intuitive touchscreen lets operators program complex cuts easily, boosting throughput without sacrificing quality.

Discover more about our smart manufacturing solutions and see how Jeenoce integrates with your SMT line at our industry solutions page. For technical insights on depaneling and automation, check out our detailed resources on the technical insights page.

Our Jeenoce Integrated Milling and Sawing PCB Depaneling Machine delivers consistent, reliable performance tailored to demanding SMT production lines. Here’s a clear breakdown of its core specs to help you choose the right fit:

Equipment dimensions(mm) | |

Width | 1300 |

Height | 1850 |

Operator height | 950 |

Weight(kg) | 1500 |

Speed of axes(mm/s) | |

Speed X-axis and Y-axis | 2000 |

Speed of Z-axis | 1000 |

Accuracy(mm) | |

Repeat accuracy | ±0.02 |

Positioning accuracy | ±0.02 |

Work space(mm) | |

Maximum acceptable PCB motherboard size | 430×350 |

PCB thickness | Generally,0.5-3.2 |

Maximum product height | 10-20 |

PCB materials | EM1、FR2、FR3、FR4、FR5 and MI-660 4.1-1984 |

Technical availability | ≥98% |

Noise level | ≤72db(A)within 1.2m |

Designed to support both high-precision milling router depaneler tasks and quick sawing operations, this unit ensures low-stress PCB singulation with minimal board damage.

For a detailed look at the integrated features and operational benefits, check out our full product overview.

This reliable, fully automated machine fits seamlessly into your manufacturing setup, reinforcing quality and throughput without compromise.

The Jeenoce Integrated Milling and Sawing PCB Depaneling Machine is designed to boost your manufacturing efficiency and increase yield significantly. Here’s how it stands out:

Higher Throughput: Servo-controlled precision reduces cycle time by up to 30%, speeding up your SMT line without sacrificing accuracy.

Reduced Material Waste: Precise milling and sawing minimize board damage and scrap rates, saving up to 15% on raw materials.

Lower Labor Costs: Automation and user-friendly touchscreen controls cut operator intervention by 40%, freeing staff for other tasks.

Cleaner Work Environment: Built-in dust extraction reduces airborne particles by 80%, improving workplace safety and reducing cleanup time.

Consistent Quality: Programmable settings ensure uniform cutting every time, reducing rework and enhancing product reliability.

| Benefit | Impact | Result |

|---|---|---|

| Cycle Time Reduction | Up to 30% faster processing | Higher output capacity |

| Material Savings | Up to 15% less scrap | Lower production costs |

| Labor Efficiency | 40% less manual intervention | Reduced operating expenses |

| Dust Extraction | 80% reduction in debris | Cleaner and safer environment |

| Cutting Accuracy | Consistent edge quality | Improved product reliability |

Integrating this milling router depaneler into your manufacturing process also translates to measurable cost savings and better ROI. Many customers report noticeable improvements in SMT line uptime and overall throughput within weeks of deployment.

For insight into how other manufacturers have optimized their PCB singulation with Jeenoce, check out our customer success stories and see how industry leaders maintain uptime and quality.

The Jeenoce Integrated Milling and Sawing PCB Depaneling Machine fits perfectly across a wide range of PCB production environments. Whether you’re working with FR4 boards, flexible PCBs, or multilayer panels, this stress-free PCB divider handles them all with precision, reducing board stress and improving yield.

Industry-Specific Scenarios

SMT Production Lines: Seamlessly integrates into automated SMT lines, providing smooth depaneling without slowing your workflow.

Electronics Manufacturing: Ideal for consumer electronics, automotive, medical devices, and telecommunications where clean, damage-free singulation is crucial.

High-Volume PCB Assembly: Designed for fast, repeatable cutting supporting mass production without compromising accuracy.

Case Study Teaser

One of our clients in automotive PCB manufacturing saw a 20% increase in throughput and a 15% reduction in material waste after switching to our combined milling router depaneler, highlighting cost savings and efficiency gains.

Compatibility Matrix Highlights

This machine supports a broad range of PCB panel sizes and thicknesses, compatible with various V-cut PCB cutting machines and tab routing setups. It works flawlessly with inline depaneling systems and automated panelizers.

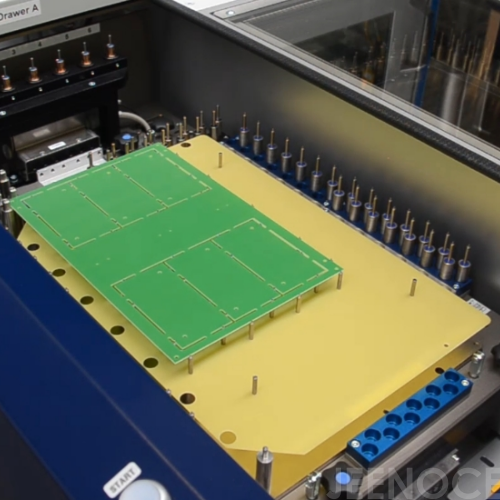

Getting started with the Jeenoce Integrated Milling and Sawing PCB Depaneling Machine is simple and designed for smooth, stress-free operation. Here’s how the whole process flows from setup to final singulation:

Load the PCB Panel

Place your FR4 board or other PCB panels securely onto the machine’s worktable. Our modular design ensures quick setup and firm holding without damage.

Program Your Cutting Parameters

Use the easy-to-navigate touchscreen interface to input the depaneling pattern. Whether it’s V-cut PCB cutting, milling routing, or tab routing, the servo-controlled movement adapts precisely.

Initiate the Automatic Depaneling

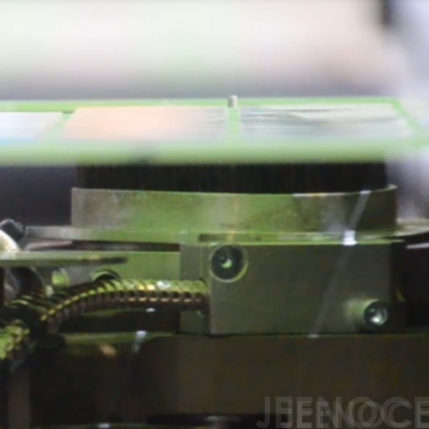

Start the machine to begin automated PCB singulation. The integrated milling router and saw system work simultaneously for clean, consistent separation with minimal stress on components.

Dust Extraction in Action

Built-in dust extraction kicks in to keep the workspace clean and extend tool life, ensuring safer, cleaner cuts throughout your production run.

Unload and Inspect

Once depaneling finishes, remove your separated PCBs. Quick inspection confirms the quality and precision of every cut.

Ready for Next Batch

Reset or adjust parameters instantly for the next panel batch, supporting high-volume SMT production with minimal downtime.

This smooth process fits seamlessly into your SMT line and supports inline depaneling workflows for maximum throughput and reliability.

The Jeenoce Integrated Milling and Sawing PCB Depaneling Machine fits seamlessly into your smart manufacturing setup. It’s designed to work smoothly alongside your SMT line, helping you maintain a steady, automated workflow without disruption.

Key Integration Features:

SMT Line Compatibility: Easily connects with existing automated placement and inspection systems.

Modular Add-Ons: Choose from dust extraction units, barcode scanners, and extra tool heads to suit your specific needs.

Software Upgrades: Keep your machine up-to-date with remote firmware updates and new cutting profiles.

Custom Settings: Program and save multiple cutting recipes via the intuitive touchscreen for diverse PCB panel types.

| Integration Aspect | Detail |

|---|---|

| Automation Interface | Supports standard protocols for SMT lines |

| Add-Ons | Dust extractor, barcode reader, tool changer |

| Software Updates | Remote & manual, with new cutting modes |

| Customizable Parameters | Cut speed, depth, pattern memory |

Ready to see how this SMT depaneling router can fit your production line? Request a personalized demo or talk to our specialists to explore upgrade options tailored for your factory.

Product type | Product output | Segmentation system |

High | Low | Offline |

Low | Low | Offline |

High | Low/Medium | Offline |

Low | High | Inline |

High | Medium/High | Inline |

To choose a suitable depaneling machine,firstly,determine whether you need an inline or offline equipment according to the above table.

And then then based on factors such as your accuracy, efficiency, dust suction, material of PCB circuit board, etc,as well as the requirements of the Party A, determine the type of depaneling machine.

Our Jeenoce Integrated Milling and Sawing PCB Depaneling Machine is trusted by industry leaders who demand precision and reliability. Customers consistently highlight its stress-free PCB divider performance and seamless integration with their SMT lines. Here’s what some of them say:

“The servo-controlled movement and dust extraction make our production smoother and cleaner – uptime has never been better.” – Electronics Manufacturing Manager

“Switching to Jeenoce’s depaneling router significantly cut our rework rates and boosted yield.” – Production Supervisor, PCB Fabrication Plant

“The modular design allowed easy adaptation to our existing automation setup, saving costs and time.” – Smart Factory Lead

Jeenoce’s commitment to quality is backed by international certifications ensuring safe and consistent operation. Our machines comply with industry safety standards, offering reliable protection and enhancing operational uptime.

With proven uptime stats averaging over 98%, our depaneling machines deliver consistent, high-volume output without compromising on precision or speed.

For deeper insights into our company values and standards behind these achievements, explore our company culture and quality commitment pages.

Investing in the Jeenoce Integrated Milling and Sawing PCB Depaneling Machine means bringing precision and efficiency to your production line without breaking the bank. We offer flexible financing options tailored to fit your budget, making it easier to upgrade your PCB singulation equipment.

Tiered Pricing Options

Basic Package: Essential features for standard SMT depaneling needs.

Advanced Package: Includes additional automation and integration capabilities.

Custom Package: Fully modular setup customized for your specific manufacturing environment.

Stock and Availability

Our machines are readily available for quick delivery to keep your production on schedule. We maintain sufficient stock to meet demand but recommend early booking for custom configurations.

Purchase Options

Direct purchase with warranty and full support

Leasing plans for short-term project needs

Trade-in offers to upgrade existing milling router depanelers

Ready to optimize your SMT line? Explore financing and ordering details or schedule a demo through our smart manufacturing solutions page to see how this inline depaneling system fits into your workflow.

Check out our versatile case studies and application examples to understand real-world benefits and explore more on our semi-automated PCB solutions.

Got questions? Our Jeenoce support team is here to help with everything about the PCB depaneling machine. From setup guidance to troubleshooting, we provide expert advice via hotline and email to keep your SMT line running smoothly.

We offer comprehensive training programs to ensure your operators get comfortable and confident with the milling router depaneler and all its functions. Plus, our warranty covers parts and service to protect your investment.

Looking for related PCB singulation equipment or upgrades? Explore our range of semi-automation solutions tailored for efficient and stress-free PCB division.

Need personalized support or want to discuss your project? Reach out anytime — we’re committed to helping you maximize efficiency and uptime with Jeenoce’s reliable depaneling technologies.

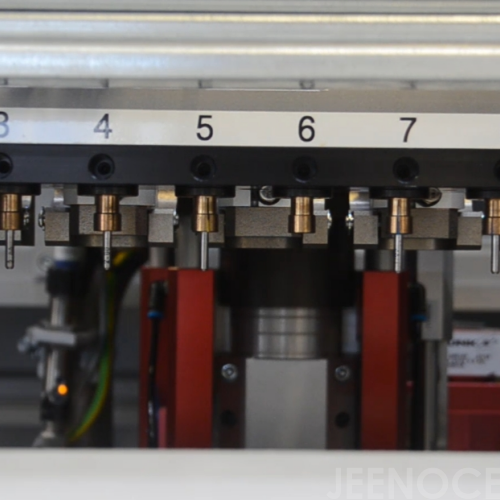

The X, Y, Z-axes magnetic levitation high-speed linear motors work along with a high-speed and precise motion control system.

The integrated dual mode of milling and sawing types of depanelization can realize smooth switching to each other and flexibly adaptation to different depaneling needs.

The dual-shuttle system greatly compresses the overall operation to increase production efficiency maximally.

The powerful software system algorithm can precisely control the segmentation force to adapt to materials of different hardness and thickness.

Ensure stable cutting of the complicated and delicate segmentation path by precisely controlling them.

Cutting precision can limit a ±0.02mm margin of error, ensuring the dimensional accuracy of precision electronic components after cutting.

Repeat precision can limit a ±0.02mm margin of error, ensuring the consistency of cutting precision of each PCB substrate during mass production.

Suitable for the fields with high requirements such as aerospace, medical electronics, automobile industry, medical pharmacy and so on.

Maintenance for the main axes of core components is easily enough to take only several minutes, requiring no professional personnel and possessing low operation threshold.

It can work stably for an extended period of time,and reducing the risk of downtime to guarantee normal production.

High stability of equipment is ensured with time-honored quality of the German engineering team.

Dynamically adjust the brush and interface to construct a relative vacuum space for actively absorbing dust.

The powerful industrial dust suction device can collect most remaining dust after PCB cutting.

Its excellent specification exceeds the standard of VDA19-1 of the German Automotive Industry Association, suitable for industries with high requirement of cleanliness such as the automotive electronics.

Simultaneously cut flexible printed circuits (FPC) and aluminum-based circuit boards (MCPCB) without replacing instruments.

With multiple functions, the single device is a mixture of a milling depaneling equipment (for high-precision curving cutting), a sawing depaneling equipment (for efficient straight cutting) and a customized depaneling device with special materials.

Accurately respond to the special circuit board production needs with the new energy vehicles’ growth, seizing the opportunity of incremental market.

It covers many fields such as consumer electronics, automotive electronics and industrial control, etc., improving order coverage and customer stickiness.

Shorten the traditional several-week cycle of “designing fixture to open-mold manufacturing” to the minute level.

A set of magnetic fixture can adapt to dozens to hundreds of PCB boards with various dimensions and shapes through digital step pins.

It can replace the traditional mode of “one product, one fixture” to avoid the high cost of endless customized special fixtures.

It is especially suitable for scenarios where with frequent iterations during the R&D stage, saving fixture purchase and inventory management costs.

The modular structure of the whole machine can make parts freely be combined like “Lego”.

Customize on the basis of special needs of clients from different businesses (customer electronics, automotive electronics and semiconductors).

The flexible investment with controllable costs does not require the one-time purchase of full-function equipment.

When a single module breaks down, it can be disassembled and replaced independently, avoiding downtime of the entire machine for maintenance.

During technology renovation, single modular parts can be upgraded independently to extend the service life of the equipment.

Message