In today’s world, nearly every gadget relies on perfect connections. Think of smartphones, cars, and even medical devices.To ensure quick and reliable connections in modern electronics, factories employ convection reflow soldering systems, an essential technology for efficient manufacturing.

JEENOCE is a global leader in Surface Mount Technology (SMT), providing specialized solutions for efficient manufacturing. We help factories use these systems to build smarter, more efficient production lines around the world.

These systems are fundamental to SMT production, the process of attaching tiny electronic components to printed circuit boards (PCBs).

Many manufacturers, however, face challenges with older methods, where uneven heating often leads to costly defects such as:

Voids: Air bubbles that weaken solder joints.

Tombstoning: Components standing up instead of lying flat.

These seemingly minor issues, such as voids and tombstoning, can ruin entire batches of PCBs, leading to significant time and financial losses.This is where convection reflow systems become a game-changer. They heat PCBs with remarkable consistency, making them ideal for industries where mistakes are not an option, such as automotive, telecom, and medical devices.

To learn more about welding defects, you can refer to this article:The Ultimate Guide to Common Reflow Soldering Faults and Solutions in PCB Assembly

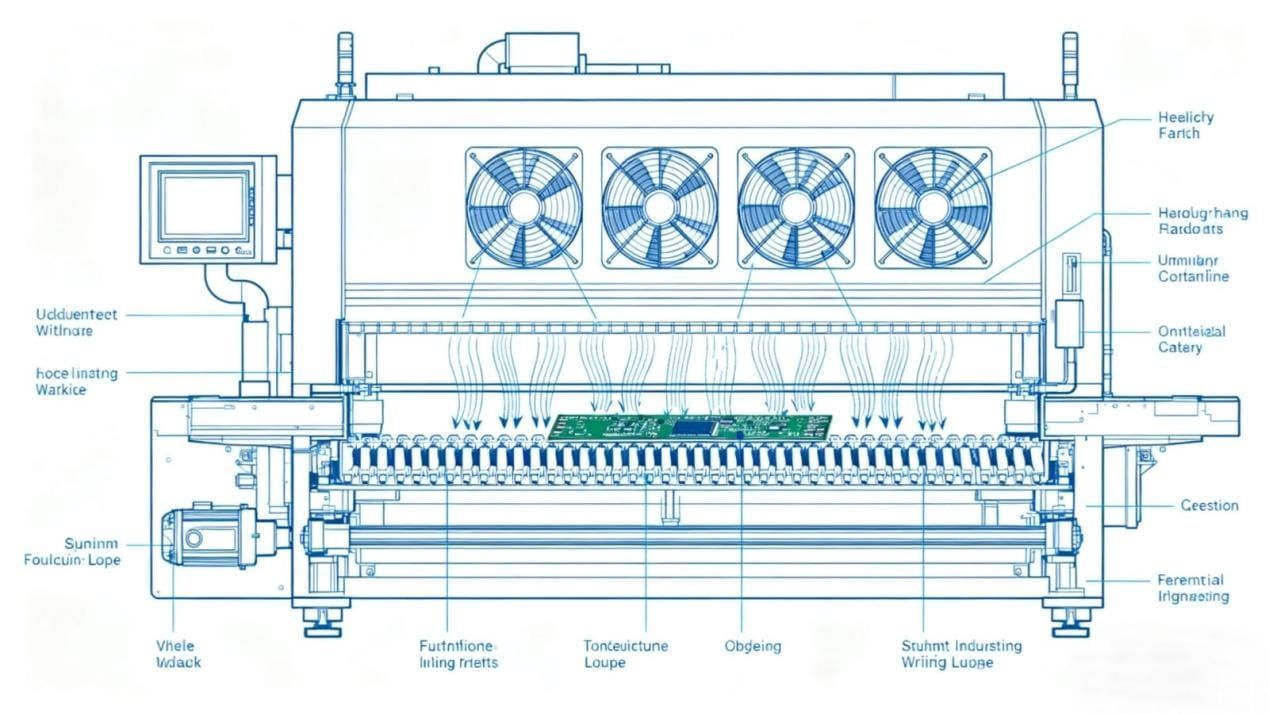

Think of a convection reflow soldering system as a "smart oven" for circuit boards. Instead of heating unevenly, it uses fans to blow hot air across the entire board. This ensures every spot reaches the same temperature at the same time.

This process is critical for SMT production. It perfectly melts the solder paste (a mix of tiny metal balls and a cleaning agent called flux) to create strong, reliable connections.

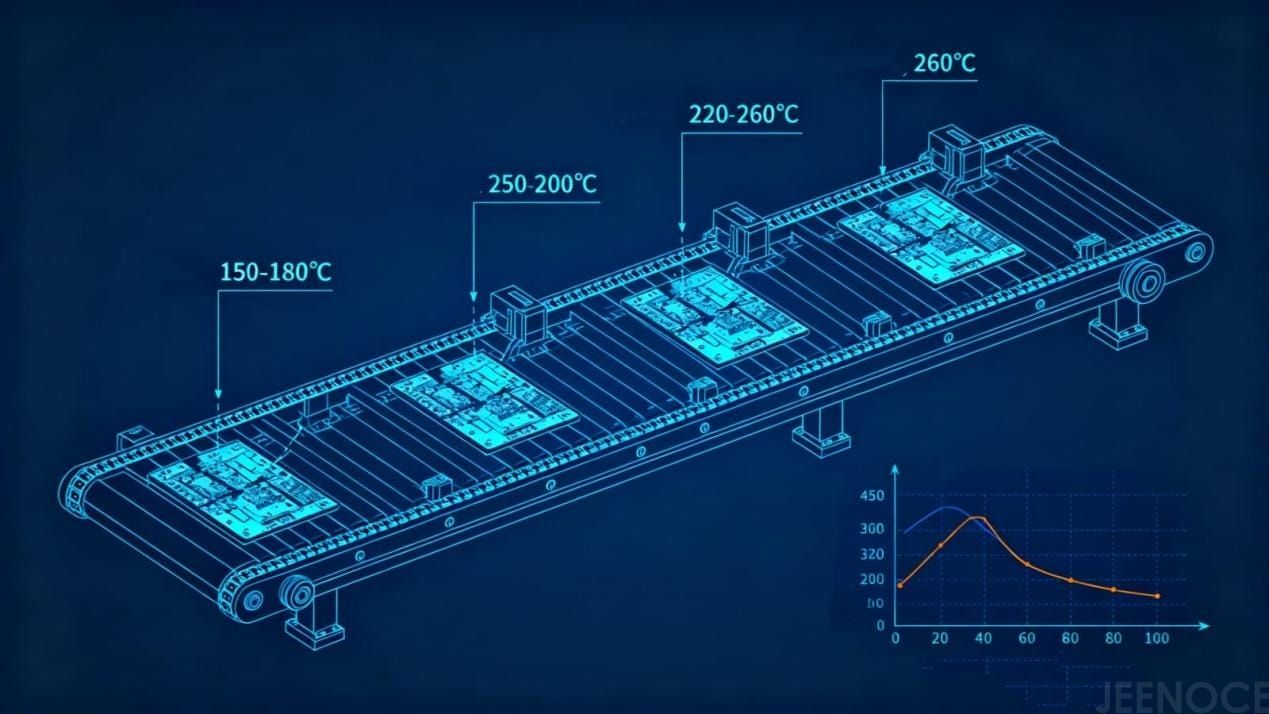

The system uses a conveyor belt to move PCBs through four distinct heating and cooling zones.

Each zone has a specific job:Preheat Zone、Soak Zone、Reflow Zone、Cooling Zone.

Many modern systems, including those from JEENOCE, also use nitrogen gas. Nitrogen is an inert gas, meaning it prevents reactions like oxidation (rust) during heating. The result is cleaner, stronger solder joints—a must for high-volume production.

To learn about the role of temperature curves in welding, please refer to this article:How Temperature Zones Make or Break Soldering Quality?

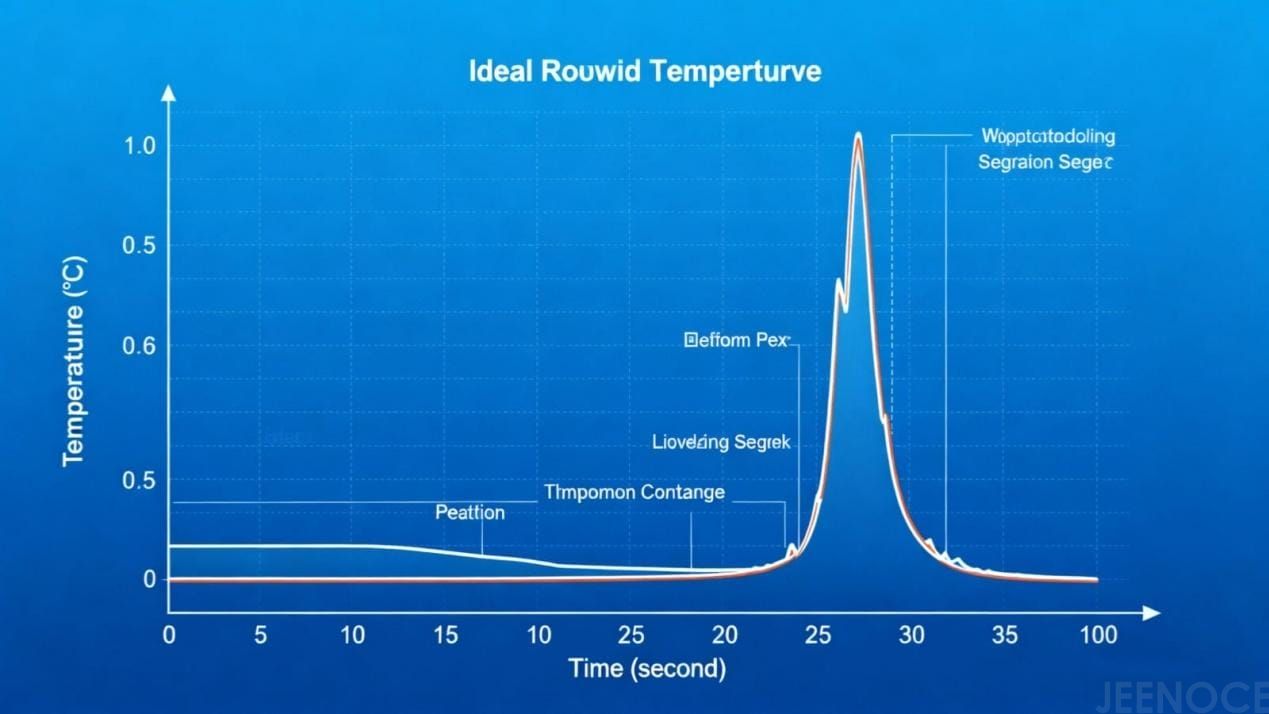

Optimizing Your Temperature Profile

Achieving the correct temperature profile is crucial for ensuring high-quality solder joints in the reflow process.

Use a thermal profiler—a device that travels through the oven with your PCB—to measure the exact temperature in each zone.

Aim for a "ramp-soak-spike" curve that matches your solder paste manufacturer's recommendations. This simple step can dramatically reduce defects.

Upgrading to a convection reflow system solves common production headaches and boosts your bottom line.

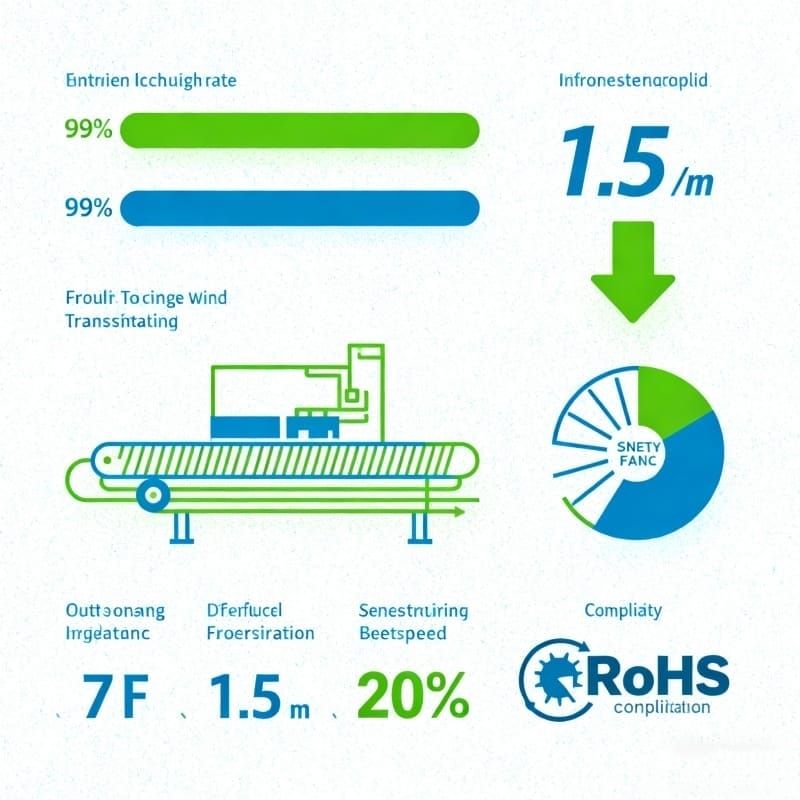

Virtually Defect-Free Production: Uniform heating reduces issues like voids and tombstoning to less than 1%. Our systems help factories achieve a "yield rate" (the percentage of good boards) of over 99%.

Increased Production Speed: Conveyor belts can move up to 1.5 meters per minute. This allows you to produce thousands of PCBs every hour, meeting tight deadlines with ease.

Significant Energy Savings: Modern systems with intelligent air circulation can cut energy consumption by up to 20% compared to older models. This directly lowers your factory's operational costs.

Versatility for Modern Electronics: These systems are perfect for lead-free solder, which is required by global standards like RoHS. They also handle complex boards with a mix of large and small components.

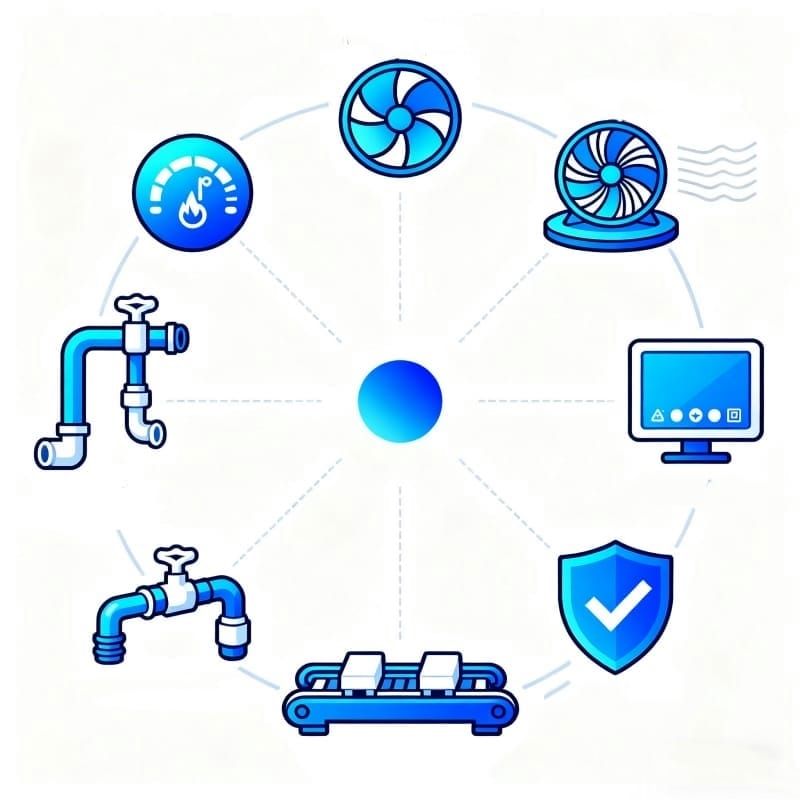

Not all convection ovens are created equal. The best systems, like those from JEENOCE, include these essential features:

Multi-Zone Heating Control: Opt for systems with 8 to 16 heating zones, as more zones provide enhanced precision and help maintain consistent temperature control. More zones allow for precise temperature control (within ±1°C), protecting sensitive components from damage.

Powerful and Uniform Air Flow: High-speed fans create what’s known as "laminar flow"—a smooth, even stream of air that eliminates hot and cold spots on the board.

Nitrogen-Ready Design: A system with built-in nitrogen capabilities gives you the flexibility to improve solder quality for high-reliability applications.

Intuitive, User-Friendly Interface: Modern systems feature touchscreen panels and IoT connectivity. This allows your team to monitor performance remotely from a computer or even a phone.

Modular and Flexible Construction: A modular design means you can add heating zones or widen the conveyor as your production needs grow.

Certified for Safety and Compliance: Ensure the machine has auto-shutoff features, alarms, and key safety certifications (like CE or UL) to meet international standards.

On top of this, JEENOCE provides its own stable, feature-rich software. Plus, our team includes 10+ R&D engineers and 20+ after-sales experts to ensure your system runs perfectly.

Read this article to find out which type of reflow soldering equipment suits you:The Ultimate Guide to Choosing the Right Reflow Soldering Machine for Your Needs

While air is fine for many applications, Consider using nitrogen for applications that require the highest reliability, such as producing:

High-Reliability Products: Such as medical, automotive, or aerospace electronics where joint failure is not an option.

Fine-Pitch Components: For PCBs with very small, tightly packed parts, nitrogen creates a cleaner surface for better soldering.

High-Volume Runs: Nitrogen reduces dross (solder waste) and maintenance, saving money over time.

In comparison to infrared (IR) and vapor phase reflow methods, convection reflow offers superior heat uniformity, making it ideal for high-density and complex boards.

It avoids the "shadow problem" seen with IR systems and provides a faster, more consistent production process compared to the slower vapor phase reflow.

Convection reflow is the go-to technology in industries where reliability is everything.

Automotive: Creates robust joints for engine control units (ECUs) and driver-assistance sensors (ADAS). A single bad joint could lead to a recall.

Telecom & Data Centers: Essential for soldering high-density boards used in 5G base stations and servers, where consistent performance is critical.

Medical Devices: Builds flawless PCBs for pacemakers, patient monitors, and imaging equipment, ensuring they meet strict FDA and safety regulations.

Rail & Aerospace: Produces electronics for signaling systems and avionics that can withstand extreme temperatures and vibrations.

JEENOCE has a proven track record with major clients like Siemens and Continental. Our automated systems have helped them cut labor costs by 30–50%, freeing up workers to focus on quality oversight instead of manual repairs.

Adding a new reflow oven to your factory should be a smooth process.

Here is how to ensure seamless integration:

Align Your Machines: First, connect the reflow oven with your upstream machines (like solder paste printers and pick-and-place robots) and downstream machines (like automated optical inspection). This creates a balanced production line without bottlenecks.

Leverage Data for Traceability: Next, integrate the system with your MES (Manufacturing Execution System) and ERP software. JEENOCE systems are designed for this, allowing you to track every single board from start to finish.

Optimize Your Workflow: Finally, fine-tune the conveyor speed and temperature profiles to match your production targets. JEENOCE offers "turn-key" solutions and expert guidance to make this setup fast and easy.

With 34 after-sales networks and a 24/7 hotline, JEENOCE provides global support to handle all the hard parts for you.

Before installation, map out your SMT line. Ensure at least one meter of conveyor space before and after the reflow oven.

This "buffer zone" prevents PCBs from bumping into each other and allows for smooth transitions between machines, which is key to preventing jams and damage.

JEENOCE offers systems tailored for every factory size and budget.

JEENOCE Customized Series (8–12 zones): Our most popular model for mid-to-high volume production. It is nitrogen-ready, features IoT connectivity, and comes with guaranteed safety stock for fast delivery.

JEENOCE ProLine 10-Zone: Engineered for demanding automotive and telecom applications. It includes advanced flux extraction to keep the oven clean and maintains strict ±1°C temperature accuracy.

Compact Inline Series (6 zones): An excellent choice for smaller factories, R&D labs, or prototyping. Its modular design allows you to add zones as your business grows.

JEENOCE is more than a supplier—we are your partner in smart manufacturing.

Global Reach, Local Support: We operate in over 50 countries across 5 continents. No matter where your factory is, our support is nearby.

Experience You Can Trust: With 10+ R&D engineers and 20+ after-sales staff, we have a proven track record with top-tier clients like Magna and Osram.

Customer-First Service: We offer yearly maintenance, on-site training, and 24/7 support with spare parts delivery in as little as 4 hours.

Digital Integration Experts: We use modern PLM, MES, and ERP software to help you build a truly connected and efficient smart factory.

Ready to boost your production quality and profits? Contact JEENOCE today for a free consultation. Visit JEENOCE’s SMT Product Page or call our 24/7 hotline.

Q1: What’s the main difference between convection and IR reflow?

A1: Convection uses heated air for uniform heating across the entire board. IR uses radiant heat, which can be blocked by tall components, creating cold "shadows."

Q2: Can convection reflow handle lead-free solder?

A2: Absolutely. Convection systems provide the precise temperature control needed for lead-free solder, ensuring you meet global environmental standards like RoHS.

Q3: Do I really need to use nitrogen in my reflow oven?

A3: It is not always required. However, nitrogen prevents oxidation, resulting in stronger and more reliable solder joints. It is highly recommended for high-reliability or high-volume products.

Q4: How does JEENOCE support customers globally?

A4: We provide support through 34 after-sales networks, a 24/7 hotline, rapid spare parts delivery, and local on-site training to ensure your production never stops.

For efficient and high-quality SMT production, convection reflow soldering systems are the superior choice. They deliver even heating, save energy, and provide the versatility needed for today's complex electronics.

JEENOCE systems stand out with their unmatched reliability, customization, and world-class global support. We empower you to produce more, with fewer defects. Don’t let outdated soldering methods hold you back.Contact JEENOCE today to upgrade your production line.

Message