As electronic gadgets become more complex, especially in automotive electronics and mixed circuit boards, traditional methods like surface mount technology (SMT) face major challenges. In this evolving landscape, the right tools are critical for ensuring smooth operation.

One such tool is the reflow machine for lead soldering, which plays a key role in achieving high-quality solder joints. This guide will help you select the best reflow machine for your needs, particularly in industries where precision is paramount.

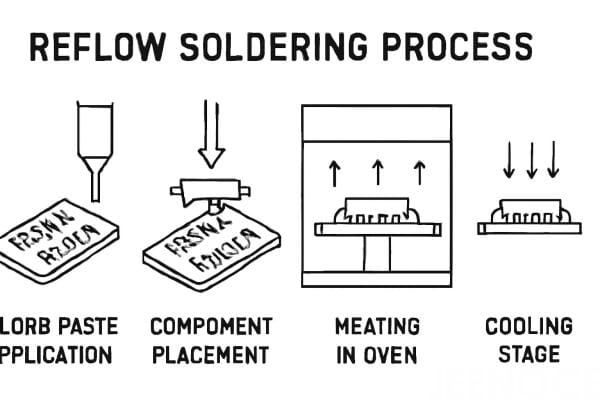

Reflow soldering involves applying solder paste to a PCB, placing components, and then heating the assembly to melt the solder. This process creates permanent electrical connections. For leaded components, maintaining precise temperature control is crucial to avoid thermal damage and ensure durable solder joints.

Reliable Connections: Ensures permanent, high-quality solder joints.

Precision: Prevents damage to sensitive components.

Efficiency: Reduces errors and improves productivity.

Reflow soldering excels in hybrid PCB assembly, where boards combine flat-mounted and through-hole components. It ensures even heat distribution, even in complex, multi-layered boards.

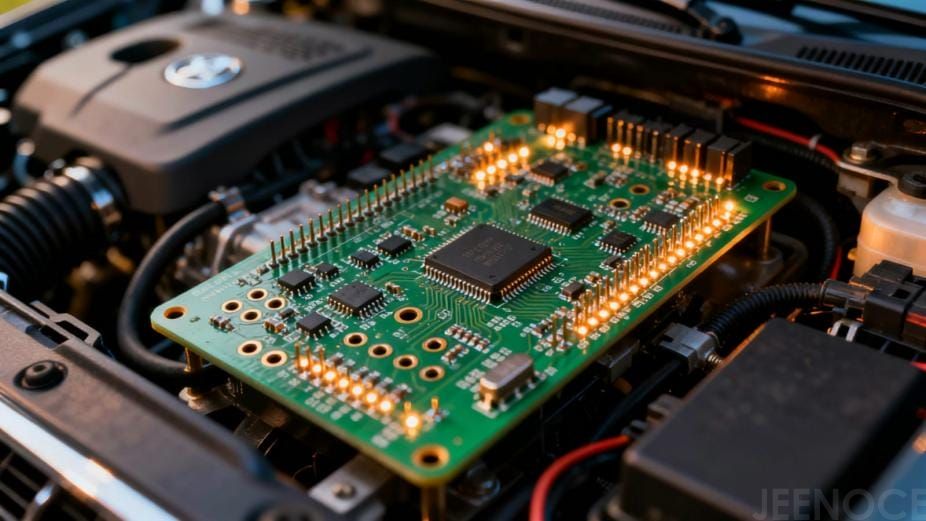

Automotive electronics operate in extreme conditions, with PCBs exposed to heat from engines and prolonged operation. A robust reflow machine with precise temperature control is essential for reliability. Defects like solder balls or cold joints can lead to safety failures, making uniform heating critical.

When selecting reflow soldering equipment for leaded components, consider the following factors:

Convection Ovens: Provide excellent heat uniformity, making them ideal for components with varying thermal mass.

Infrared Ovens: Offer rapid heating but require precise profiling to prevent localized overheating.

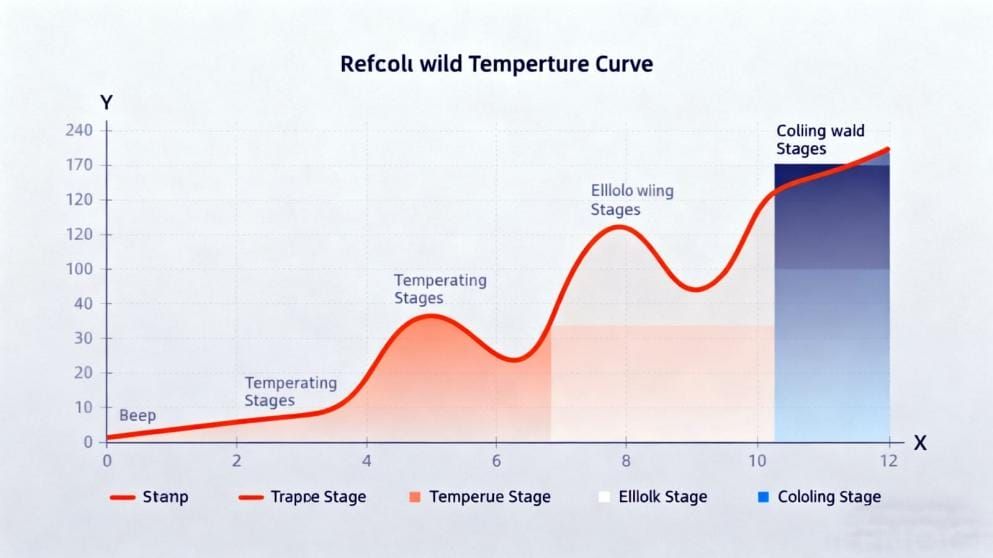

A well-defined temperature profile is essential for accommodating the thermal characteristics of leaded components. This helps prevent issues like cold solder joints and component damage.

In a project with a major car parts manufacturer, we faced challenges with lead soldering on dashboard boards. By using a convection reflow machine, we achieved consistent heat distribution, resolving the previous issue of flaky joints. This improvement boosted output by 20%, and the client reported a significant reduction in rework.

"This changed our game—no more rework headaches."

Tip: For high-volume automotive projects, convection reflow machines are recommended. Infrared machines are better for quick, precise heating of complex components.

Unlike standard SMT, which uses rapid heating cycles, reflow soldering offers more controlled heat distribution. This is crucial for through-hole leads, which may shift during the process.

In contrast to wave soldering, reflow machines provide a more controlled oven profile, ensuring precision. This consistency can reduce defects by up to 30%, especially in tight, complex builds like car sensors.

To keep your reflow machine running at peak performance, follow these maintenance tips:

Regular Cleaning: Clean heating elements and conveyor belts to prevent flux buildup.

Calibration: Calibrate temperature sensors regularly to ensure accurate profiles.

Component Inspection: Inspect and replace worn parts, such as fans and heaters.

Quick Tip: Set a calendar reminder for regular cleanings using lint-free cloths and mild cleaners. Avoid harsh chemicals to protect your equipment.

Note: A well-maintained reflow machine can last over 10 years, while neglecting maintenance can lead to a 15% increase in defects.

At Jeenoce, we specialize in smart manufacturing and customized automation solutions. Our reflow systems, built with AI, adapt heat profiles in real-time. This helps solve complex issues like vibration-proof solder joints in automotive electronics.

We recently deployed a convection reflow system for a car electronics manufacturer. Their lead technician said, "The consistent temperature and fast welds improved our reliability tremendously."

This feedback confirms that reflow machines not only save time but also reduce production headaches.

Reflow machines are essential for lead soldering in hybrid PCB assemblies and automotive electronics. They improve both efficiency and quality, ensuring that even the most challenging jobs are completed flawlessly.

Looking for the best reflow soldering machine for lead soldering in PCBs? Contact our team for expert recommendations and custom solutions tailored to your needs.

For more on reflow soldering techniques and equipment, explore these resources:

[Reflow Soldering Process Overview]

Message