In today’s electronics manufacturing, reflow soldering machines are essential. They attach components to circuit boards quickly and accurately. As production needs grow, choosing the right machine—like the TSM or EPS RF 300、Rehm—is more important than ever.

This article looks at the specs, performance, and best uses of these machines. By understanding these options, manufacturers can choose wisely and improve their SMT lines.

Reflow soldering machines use hot air or convection to melt solder paste. This creates strong connections betwen parts and circuit boards.

In SMT assembly, these machines are vital. They attach components safely without harming delicate electronics.

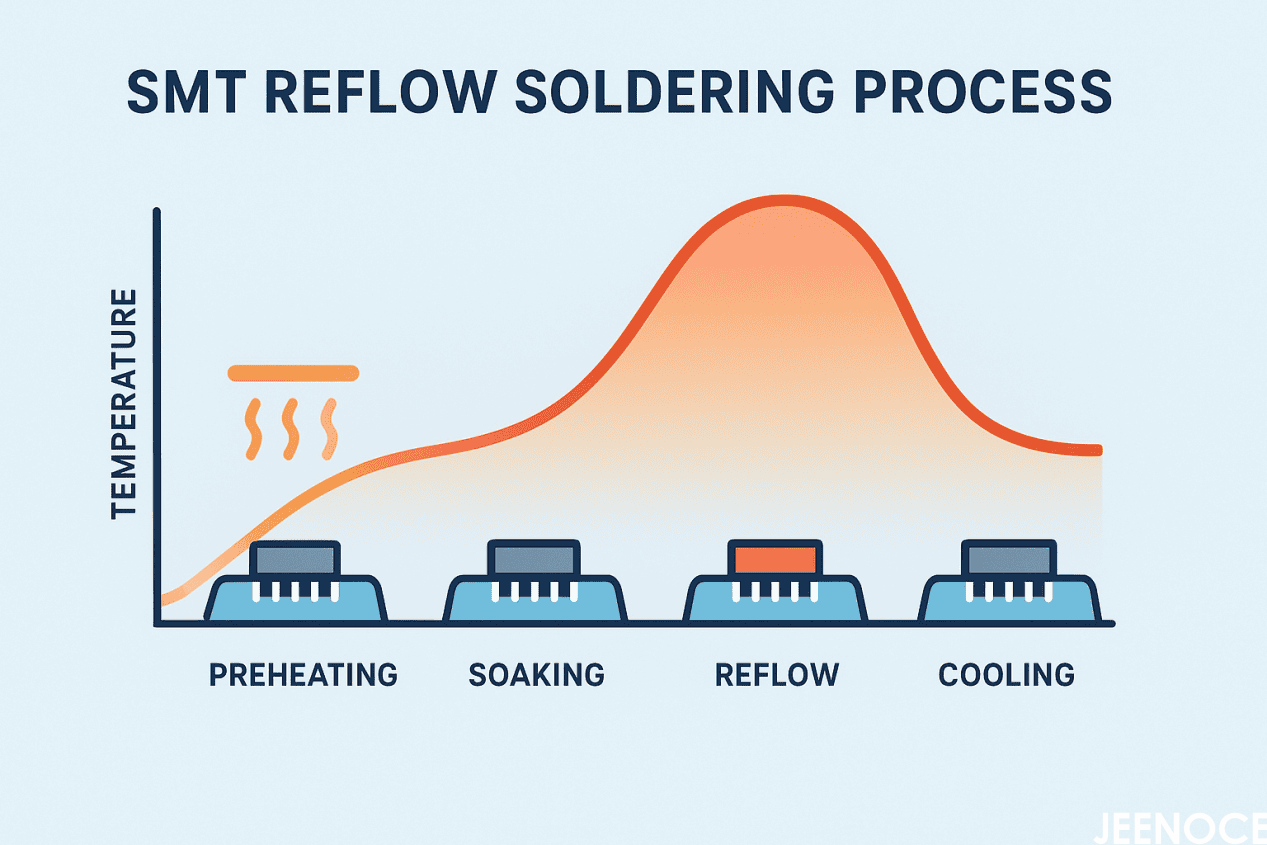

Preheating: activates the flux

Soaking: spreads heat evenly

Reflow: melts the solder

Cooling: solidifies the joints

All steps are controlled by precise temperature settings.

Because of this, reflow soldering machines are crucial in large-scale production. They help keep quality high and defects low.

The TSM reflow soldering machine, manufactured by TSM Technology System Machinery, features precise temperature control for consistent soldering outcomes. This makes it a good fit for mid-sized factories.

Leveraging optimized nitrogen purge systems and modular heating zones, the TSM machine ensures uniform thermal distribution while minimizing gas consumption. That’s why it’s ideal for precise soldering with low waste.

Key benefits include:

Temperature Control: Heats up to 350°C for perfect soldering.

Heating Zones: Multiple zones for even heat spread.

Cooling Zones: Cools solder joints quickly and firmly.

These features make the TSM machine reliable and eco-friendly for many SMT tasks.

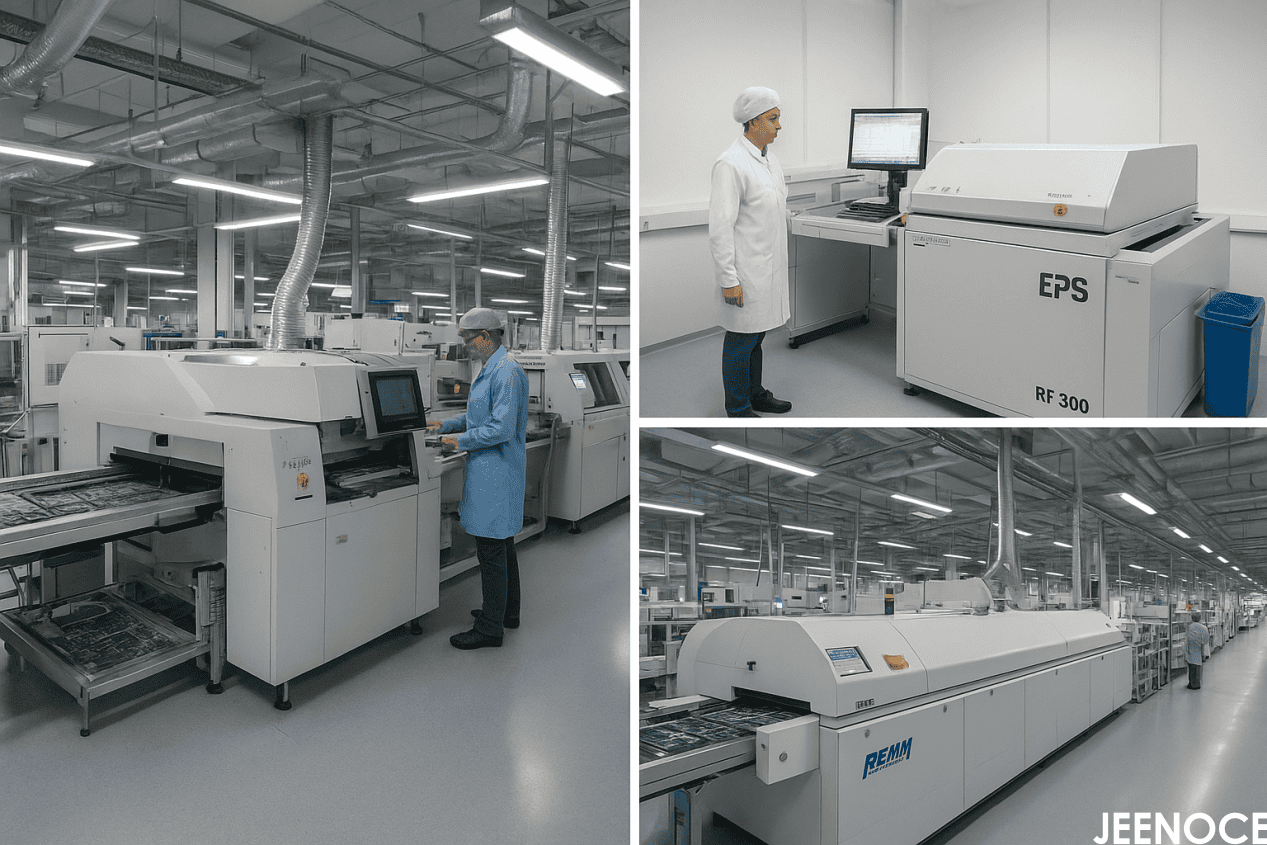

Engineered for small to medium-scale production, the EPS RF 300 leverages plenum convection heating to achieve uniform temperature distribution even at reduced thermal settings.

This compact system can be programmed with up to 100 profiles. That makes it great for labs and trial production.

Notable features:

Heating Capacity: Up to 300°C for various soldering needs.

Heating Zones: 6 zones (3 top, 3 bottom) for fine control.

Conveyor Speed: Adjustable to fit the production line.

Power Needs: Runs on 410 VAC, 3-phase power.

The EPS RF 300 offers a good balance of performance and cost for changing production needs.

Think about:

How many boards you make?

How precise you need to be?

Your budget?

Also consider:

Production scale.

Balance of speed and accuracy.

How it fits with your current line.

Energy use and eco-friendliness.

By comparing these factors, you can choose a machine like the TSM or EPS RF 300 to boost quality and save money.

Learn how to select the perfect reflow soldering solution in our expert article:

The Ultimate Guide to Choosing the Right Reflow Soldering Machine for Your Needs

Rehm Thermal Systems leads the market with its Vision and Condenso series. These machines use vacuum-assisted convection to make perfect, void-free solder joints. They can handle temperatures up to 240°C.

As JEENOCE’s main partner, Rehm provides custom reflow solutions that improve efficiency worldwide.

Main advantages:

Saves Energy: Uses smart insulation and low-nitrogen designs to cut costs.

Smart Controls: The Nexus vacuum system auto-adjusts to reduce errors.

Works for Many Uses: Good for small prototypes and large power modules.

JEENOCE helps clients get the most from Rehm machines with tailored setups.

Feature | TSM | EPS RF 300 | Rehm (Vision/Condenso) |

Heating | Zones | 6 zones | Multiple |

Cooling | Yes | Yes | Yes |

Convection Type | Air | Hot air | Convection/Vapor |

Vacuum Option | Optional | No | Yes (Vision series) |

Energy Efficiency | Standard | Standard | High |

Best For | Medium production | High volume | Precision soldering |

At Jeenoce, we know how important Rehm reflow machines are for electronics making. We supply top-quality Rehm equipment to help clients work faster, save money, and solder better.

Here are two success stories:

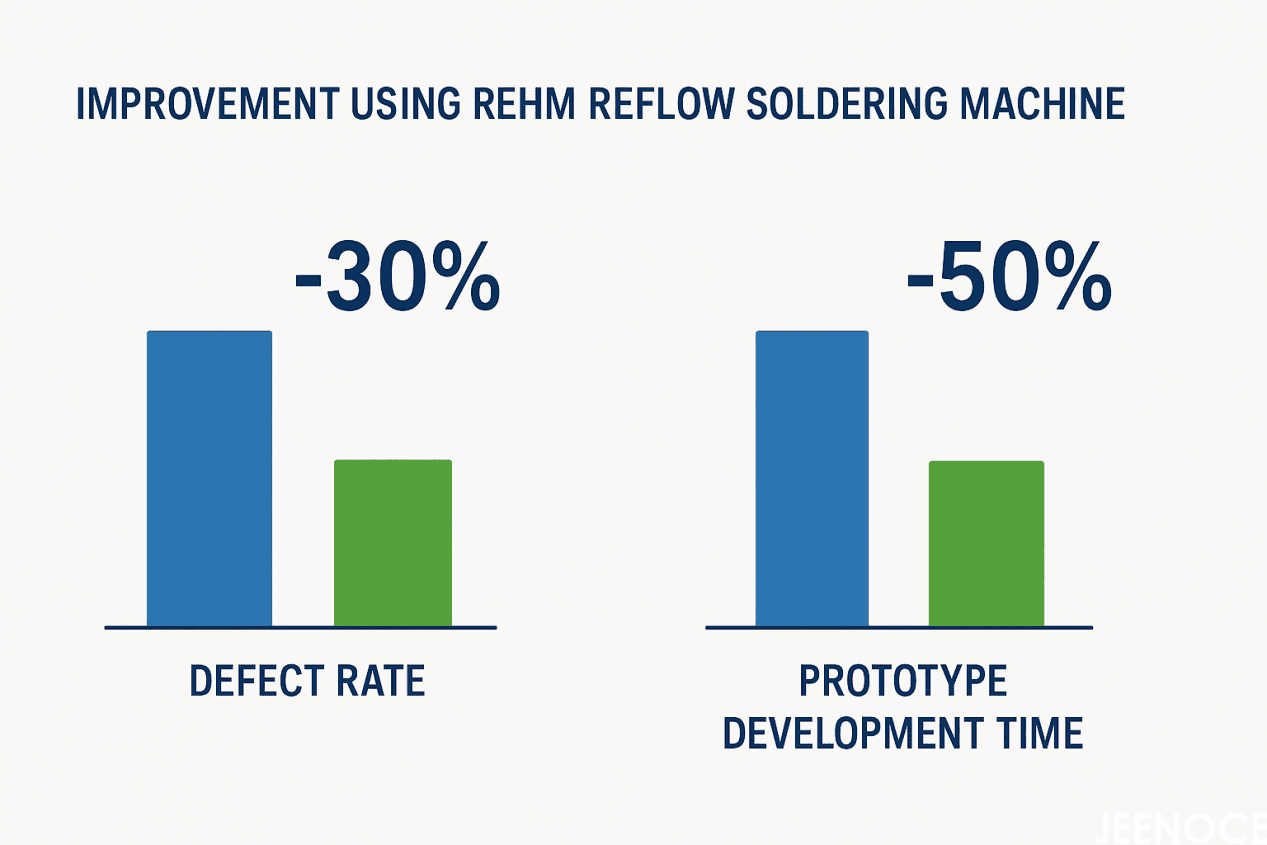

A client making IoT devices had soldering problems. Joints were uneven and had too many voids. We suggested the Rehm VisionX machine.

With its precise heat and vacuum control, the VisionX cut void rates and improved joint quality. The client’s prototyping time dropped by 50%—from weeks to days. They now meet IPC standards easily. The machine’s flexibility supports fast design changes.

A smartphone maker had oxidation issues and high energy use.

Its oxidation-free soldering kept joints clean even at high heat. Low nitrogen use cut energy costs. After installing Condenso, defect rates fell by 30%. Energy bills dropped. The client now meets global demand with better consistency.

With Rehm machines, Jenos helps clients solve soldering challenges, improve efficiency, and ensure quality. Rehm’s tech is efficient, reliable, and green. We’ll keep offering custom solutions to keep our clients competitive.

Looking at the TSM, EPS RF 300, and Rehm machines, Rehm stands out. Its vacuum tech, energy savings, and smart controls make it the best choice for modern makers.

As precision and green standards rise, teaming up with JEENOCE for Rehm solutions brings custom quality. Check your production needs today to pick the right reflow soldering machine for your future growth.

Message