Explore the reflow soldering oven market, projected to reach $1.067B in 2025 with a CAGR of 4.1%. Key trends in SMT integration, investment opportunities, and how JEENOCE provides turn-key solutions for EMS manufacturers. Lead with expert insights.

The reflow soldering oven market is growing rapidly, driven by advancements in electronics manufacturing. By 2025, the market is expected to reach $1.067 billion, with a CAGR of 4.1%.

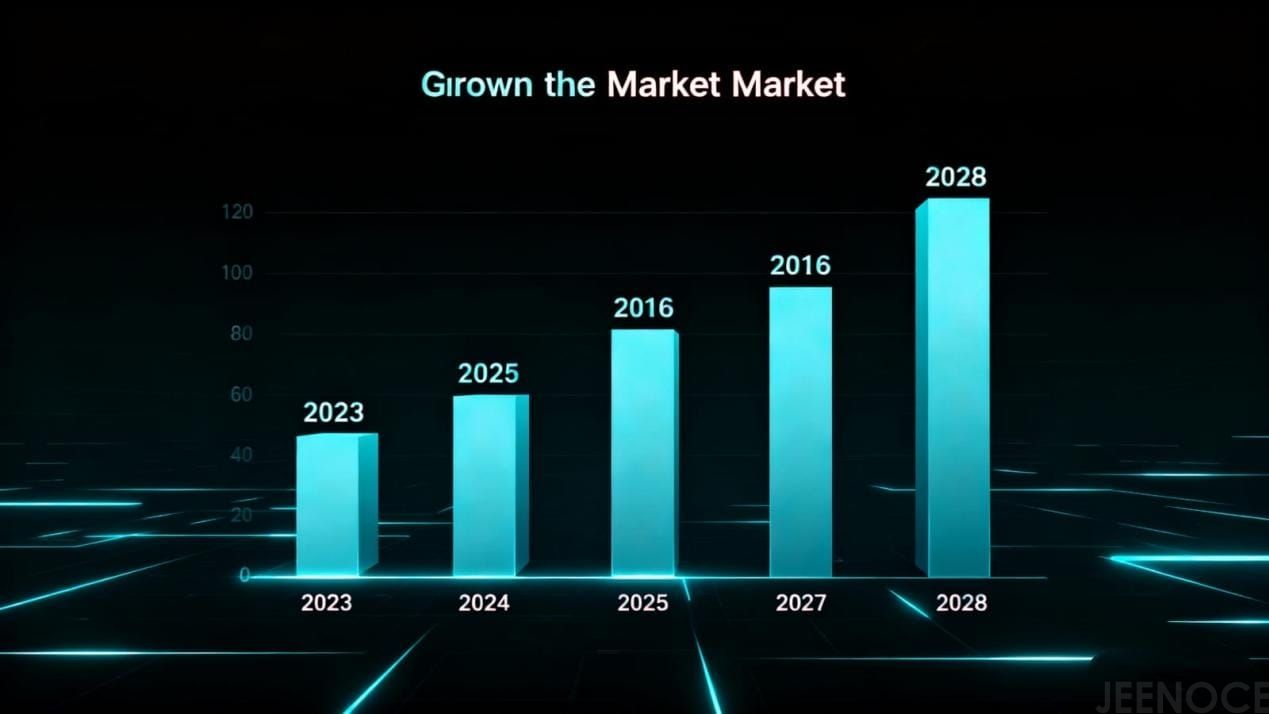

The market size projections for the coming years are as follows:

2023: Market size of $2.4 billion

2024: Market size of $2.6 billion (CAGR of 4.5%)

2028: Market size expected to reach $3.4 billion (CAGR of 6.0%)

These growth rates are fueled by key drivers, including the rising demand for semiconductors, 5G technology, automotive electronics, and renewable energy transitions.

The Asia-Pacific region, particularly China, holds the largest market share, accounting for 55-60% of global sales due to its strong electronics manufacturing base.

As we look ahead to 2025, several major trends are shaping the market. Let’s explore these trends:

Market Size in 2024: $1.28 billion

Projected CAGR: 4.1%, doubling by 2033

Nitrogen reflow ovens prevent oxidation during the soldering process, resulting in better joint quality (up to 20% improvement). This technology is especially beneficial for automotive and medical electronics.

Market Size in 2024: $1.28 billion

Projected to reach: $1.85 billion by 2030

These systems reduce defects by 15-18% by removing air from the reflow process. Paired with AI, these systems are expected to become even more precise.

Integration of MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning) improves production visibility and efficiency. JEENOCE’s Digital Twin system is one example that helps manufacturers spot issues early in production.

Benefit: Shinier joints and fewer cracks.

Benefit: Reduced scrap, leading to more environmentally friendly processes.

Benefit: Real-time data insights, increasing overall production efficiency.

These trends are leading to smarter, more efficient SMT (Surface Mount Technology) production lines.

【Tip: Implementing nitrogen or vacuum reflow ovens may be an ideal choice for businesses focusing on high-reliability applications like automotive or medical devices.】

Investing in a modern reflow soldering oven offers substantial returns. A typical ROI period is 2-3 years. Factories can potentially save between $20,000 to $40,000 annually through:

Increased yield

Reduced downtime

While supply chain disruptions may pose challenges, the growth opportunities are significant, especially with the potential for expanding production lines. JEENOCE's turn-key solutions help minimize risks by offering:

Equipment selection

Installation

Debugging services

The reflow soldering oven market is competitive but offers opportunities for growth. Key players include Heller, BTU, and Rehm. JEENOCE, a rising star in the Asia-Pacific region, specializes in custom automation solutions for electronics manufacturers.

Supplier | Market Share (2025) | Core Technology | Global Reach | JEENOCE Advantage |

Heller | 13.8% | High-throughput SMT | Global | Focus on custom solutions with proprietary IP |

BTU | ~10% | Vacuum/Nitrogen systems | Americas/Europe | Strong after-sales support across 50+ countries |

Rehm | 11% | Digital technology | Global | Full-service offerings reducing costs by up to 15% |

JEENOCE | Mid-size (15% growth in Asia) | SMT Integration + ERP | 5 Continents | Custom, client-first solutions with industry partnerships |

【Tip: When selecting a supplier, consider after-sales service. JEENOCE provides 24/7 support across 34 networks, ensuring your operations run smoothly.】

JEENOCE provides a comprehensive range of SMT full-line integration, semiconductor packaging, and custom automation solutions. Our services include everything from equipment procurement and customs clearance to installation and commissioning.

Over 38 professionals with international experience.

Presence in 50+ countries.

Customer-first approach to delivering tailored solutions.

The reflow soldering oven market, with its projected growth, presents a strong investment opportunity. Intelligent technologies and sustainability trends are key drivers of this growth. By making informed investments and selecting the right partners, manufacturers can thrive in this evolving landscape.

At JEENOCE, we are ready to be your trusted partner. With over eight years of expertise, we offer customized solutions designed to optimize your production processes.

Ready to upgrade your equipment? Contact us for a free consultation.

Q: What is the projected CAGR for the reflow soldering oven market?

A: The market is expected to grow at a CAGR of 4.1-6.2% from 2024 to 2028.

Q: What are the advantages of nitrogen reflow ovens?

A: Nitrogen reflow ovens prevent oxidation during soldering, improving joint quality and reliability—especially in critical applications.

Q: How is ROI calculated for a reflow oven investment?

A: ROI is calculated using the formula: (Net Gain from Investment / Cost of Investment) × 100%. The payback period is typically 2-3 years, with savings through defect reduction and improved yield.

Q: What are the primary applications of reflow soldering ovens?

A: These ovens are essential in electronics manufacturing, particularly for automotive electronics, telecommunications, and consumer electronics.

Message