Galden fluid is essential in vapor phase soldering (VPS), but its high cost and ongoing consumption pose a significant challenge. To keep your VPS line efficient and cost-effective, managing Galden use is crucial. Overconsumption not only inflates costs but also leads to frequent downtime for fluid replacement and disposal, impacting yield. By adopting targeted strategies to control evaporation loss, prevent contamination, and implement effective recovery systems, you can extend the service life of your Galden fluid dramatically. This reduces expenses, minimizes waste, and boosts overall line reliability. In this guide, you’ll find practical, engineering-backed solutions to slash your Galden consumption without compromising process quality or throughput.

Galden fluid remains the single biggest expense in vapor phase soldering (VPS) operations, especially with high-spec grades like HT170 to HT270. Over the last few years, prices for these PFPE fluids have steadily risen due to raw material shortages and tighter environmental regulations. For a standard 400–600 mm VPS machine, monthly Galden consumption typically ranges from 10 to 30 liters—translating to thousands of dollars spent just on fluid replacement.

But the cost impact goes beyond the price per litre. Hidden expenses like machine downtime during fluid top-offs or replacements, disposal fees for spent Galden, and quality losses caused by fluid contamination or degradation can add up quickly. Yield impact is often overlooked, yet poor Galden management can lead to inconsistent thermal profiles, solder defects, and increased rework. Tackling these cost drivers is critical for any production line aiming to optimise SMT vapor phase cost reduction and improve overall efficiency.

To manage Galden fluid consumption effectively in vapor phase soldering, it’s crucial to understand where most of the losses come from. There are three main sources:

Primary Evaporation Loss (Boiling + Drag-Out)

The biggest culprit is evaporation during the soldering process. Galden boils at high temperatures, and some vapor naturally escapes. On top of that, “drag-out” happens when boards or nozzles pull a thin film of fluid out of the vapor zone as they move through, increasing loss.

Secondary Loss via Decomposition and Oxidation

Over time, Galden fluid breaks down chemically due to heat exposure. This leads to oxidation and decomposition, reducing fluid purity and performance. Degraded fluid often needs replacing, adding to your consumption costs.

Leakage and Mechanical Loss

Small leaks from machine seals, gaskets, or fittings cause fluid to drip out unnoticed. Mechanical wear and improper maintenance can worsen these leaks, leading to steady fluid loss that’s easy to overlook.

Addressing these three loss sources is key to cutting down Galden consumption on your vapor phase soldering line and extending fluid life.

Controlling Galden evaporation loss in vapor phase soldering starts with fine-tuning your process window and temperature profiling. Keeping the system just hot enough to ensure quality soldering—but no hotter—can drastically cut boil-off. Precise temperature control means less fluid boils away unnecessarily.

Next, upgrading to advanced condensation rings and modern cooling coil designs is a game-changer in 2024–2025 best practices. These parts efficiently capture Galden vapor before it escapes, funneling it back into the system. Pairing this with active secondary cooling systems and heat exchanger upgrades further reduces vapor loss by rapidly condensing and recycling fluid vapor.

Don’t overlook nozzle design and board entry/exit speeds. Optimizing nozzle shape minimizes fluid drag-out, and adjusting conveyor speeds ensures the board spends the right time in the vapor zone—no faster, no slower—which helps limit fluid carry-away on boards.

Vacuum vapor phase soldering (VPS) offers proven Galden savings compared to standard VPS lines. By lowering pressure inside the chamber, evaporation is significantly reduced. Real data shows vacuum VPS systems can cut Galden consumption by up to 30%, making them a smart choice where fluid cost control is critical.

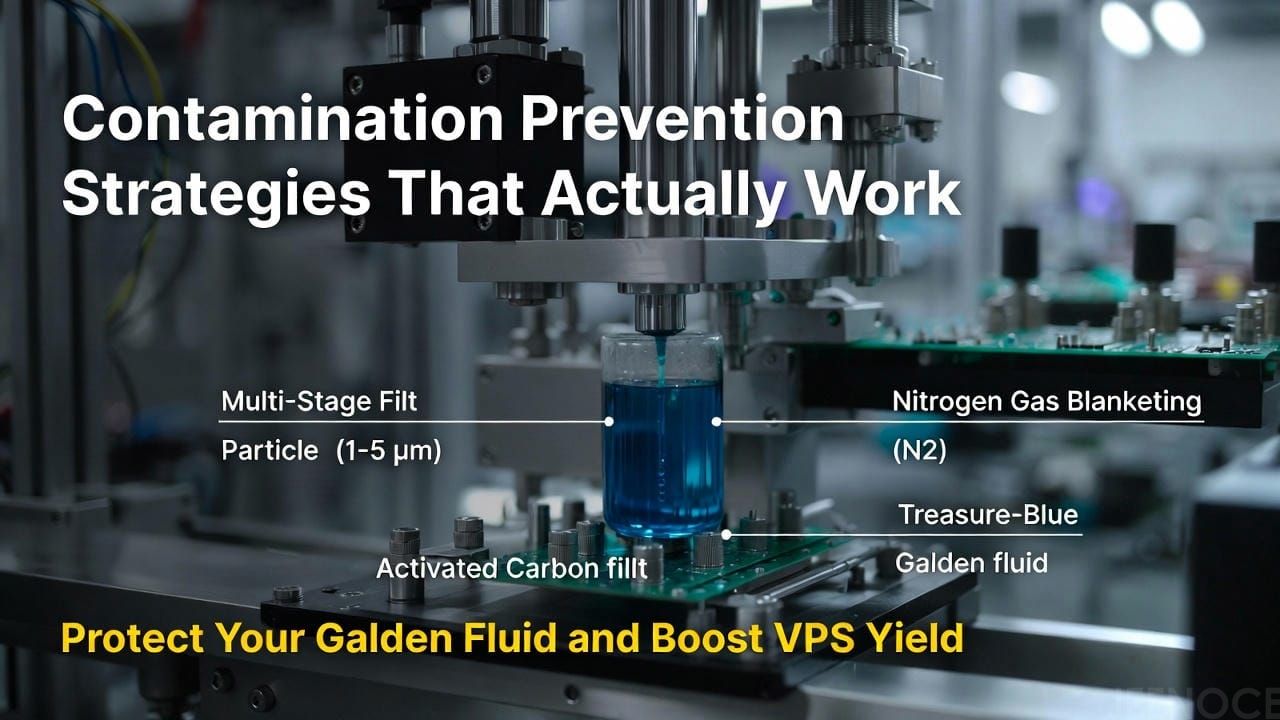

Contamination in Galden fluid is a major reason for premature fluid degradation and increased costs in vapor phase soldering (VPS). The main culprits are flux residue, moisture ingress, airborne particles, and ionic contaminants. These impurities affect fluid purity, boiling points, and ultimately, solder quality.

Choose multi-stage filtration that targets particles between 1–5 μm, combined with activated carbon filters to trap organic residues. This setup keeps the Galden fluid clean longer, reducing the frequency of costly fluid replacements.

Implement a consistent testing schedule to monitor fluid health, checking the acid number, boiling point stability, and overall contamination level. Early detection through routine analysis saves downtime and costly troubleshooting.

Blanketing the Galden fluid with nitrogen gas significantly minimizes oxidation and moisture absorption. While initial investment might seem high, the ROI is proven—extending fluid life and improving process stability.

Regular inspections and timely replacements of machine seals and gaskets prevent leaks and external contamination. A tight, well-maintained VPS chamber reduces contamination risks and fluid loss, ensuring consistent Galden performance over time.

By combining these contamination control strategies, you’re not only protecting your Galden investment but also enhancing overall VPS yield and reliability.

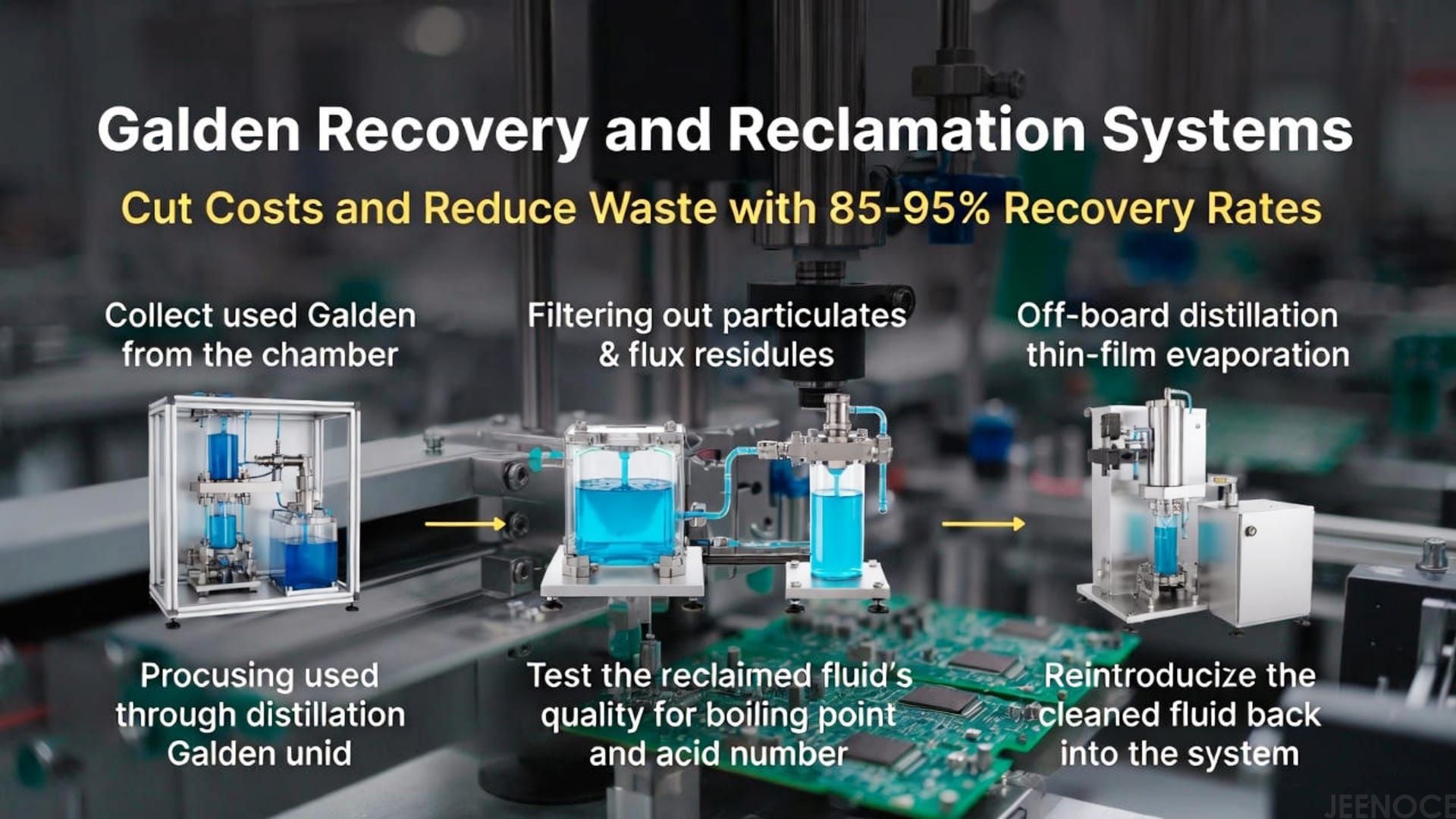

Managing Galden fluid waste with effective recovery and reclamation systems is a smart way to cut costs and reduce environmental impact. You can choose between on-board distillation units, which are integrated directly into the vapor phase soldering (VPS) machine for continuous recovery, or off-board distillation systems that process used fluid separately. Each has its pros and cons depending on your facility size and throughput needs.

The latest 2025 recovery technologies bring exciting advancements such as molecular distillation and thin-film evaporation. These methods offer gentle fluid treatment, preserving Galden’s chemical integrity while removing contaminants, pushing fluid recovery rates to 85–95% with modern setups.

A typical step-by-step fluid reclamation process generally includes:

Collecting used Galden from the vapor soldering chamber

Filtering out particulates and flux residues

Passing fluid through distillation units to separate contaminants

Testing reclaimed fluid quality (boiling point and acid number)

Reintroducing cleaned fluid back into the VPS system

Recovered Galden remains compatible with common grades like HT200. HT230. and HT270, ensuring no compromise in soldering profile or machine performance. For a detailed look into these cutting-edge recovery systems, check out the insights on advanced fluid reclamation processes that highlight practical implementation and gains.

By adopting modern recovery setups, you not only save on fresh fluid purchases but also lower disposal costs and downtime, making your VPS line both greener and more cost-efficient.

Keeping Galden fluid in top shape means following a solid maintenance schedule. Regular checks help slash unnecessary fluid loss, catch contamination early, and keep your vapor phase soldering (VPS) line running smoothly.

Inspect condensation rings and cooling coils for buildup or damage

Confirm nozzle seals are intact to prevent leaks

Monitor fluid boiling points for early signs of degradation

Clean filtration systems to avoid clogging and contamination

Check and replace any worn gaskets or machine seals

Verify inert gas blanketing system (if used) is functioning properly

Perform acid number tests and fluid contamination analysis

Examine fluid clarity and check for particulate matter

Inspect heat exchangers and cooling system efficiency

Drain and inspect fluid reservoir for sludge or breakdown residues

Service and replace key spare parts, including seals, filters, and nozzles

Calibrate temperature profiling and vacuum controls to ensure optimal process conditions

Seals and gaskets specific to your VPS machine model

Replacement filtration cartridges (1–5 µm + activated carbon)

Spare nozzles designed for minimal drag-out

Cooling coil cleaning tools and parts

Stick to this schedule to extend Galden life, cut down fluid consumption, and avoid costly downtime.

Regular upkeep isn’t just about fluid—it’s about safeguarding the entire soldering process for long-term efficiency and cost savings.

Several companies have seen impressive results by optimizing their Galden fluid management in vapor phase soldering.

Automotive Tier-1 Manufacturer:

By implementing a comprehensive Galden evaporation loss control strategy—focusing on improved condensation ring design, advanced cooling coil upgrades, and regular fluid analysis—they slashed Galden costs by 68% within just 12 months. This cut not only reduced fluid consumption but also lowered downtime and disposal fees significantly.

Medical Device Manufacturer:

A precision-focused medical device company extended their Galden fluid lifespan from 4 months up to 18 months. They achieved this by integrating rigorous contamination prevention practices, including multi-stage filtration systems and inert gas blanketing, combined with an onboard distillation recovery unit to reclaim and reuse high-quality fluid effectively.

These real-world examples prove that smart Galden management cuts expenses and boosts efficiency across industries.

Keeping your vapor phase soldering (VPS) line efficient means embracing smart Galden management with the latest technology. IoT fluid monitoring sensors now allow real-time tracking of Galden levels, temperature, and contamination. These smart sensors give instant alerts when fluid quality drops or levels run low, so you can act before losses spike.

Pairing these sensors with advanced platforms like Jeenoce’s smart SMT integration makes predictive maintenance a reality. By analyzing data trends, the system predicts when Galden needs topping up or replacing, reducing unplanned downtime and cutting waste. Plus, automation and continuous data logging cut human error dramatically — no more guesswork or missed maintenance steps.

Using these smart tools not only extends fluid life but also slashes overall costs on your VPS line. Embrace smart Galden management now — it’s the future of cost-effective, reliable vapor phase soldering.

To make Galden fluid management in vapor phase soldering easy and effective, here’s a quick checklist you can keep handy. Use this guide to slash evaporation loss, prevent contamination, and maximize fluid life—all vital for cutting costs in your VPS line.

Monitor and maintain optimal process temperature settings

Regularly inspect and clean condensation rings and cooling coils

Upgrade cooling systems and use active secondary cooling where possible

Optimize nozzle design and board entry/exit speed to reduce drag-out

Consider vacuum VPS technology for proven Galden savings

Keep filtration systems up to date (1–5 μm filters + activated carbon stage)

Follow routine fluid analysis schedules (test acid number, boiling point, contamination)

Use inert nitrogen blanketing to minimize oxidation

Maintain machine seals and replace gaskets regularly

Implement on-board or off-board distillation units for fluid recovery

Choose modern methods like molecular distillation and thin-film evaporation

Track recovery rates aiming for 85–95% efficiency

Test reclaimed fluid compatibility with your Galden grade (HT200. HT230. HT270)

Follow daily, weekly, monthly, and quarterly fluid and equipment checklists

Keep recommended spare parts and service kits ready for quick replacement

This streamlined tool helps teams stay consistent and proactive in managing vapor phase soldering fluid costs.

Make your VPS line more efficient and cost-effective by sticking to this checklist—keeping Galden loss and contamination tightly controlled. For more on advanced fluid management and innovative VPS solutions, check out our technical insights on condensation ring design and fluid recovery systems.

Modern PFPE fluid recovery systems drastically cut your Galden consumption, typically saving 85–95% of the fluid through efficient distillation or thin-film evaporation. This means less frequent top-ups and big cost savings, especially on higher-grade fluids like HT200 or HT270. Onboard recovery units integrated into your VPS line can make reclaiming Galden seamless and reduce downtime.

Yes. When properly reclaimed, Galden retains its purity and thermal stability, making it fully compatible with lead-free solder profiles. Regular fluid analysis (checking acid number and boiling point) ensures the recovered fluid meets required specs, so you get reliable, repeatable results without compromising quality or introducing contamination.

Among commonly used grades, Galden HT270 typically exhibits the lowest evaporation rate due to its higher boiling point and molecular stability. However, choosing the right grade depends on your soldering temperature profile and machine setup. Optimizing temperature windows along with proper evaporation loss control extends fluid life regardless of grade.

Message