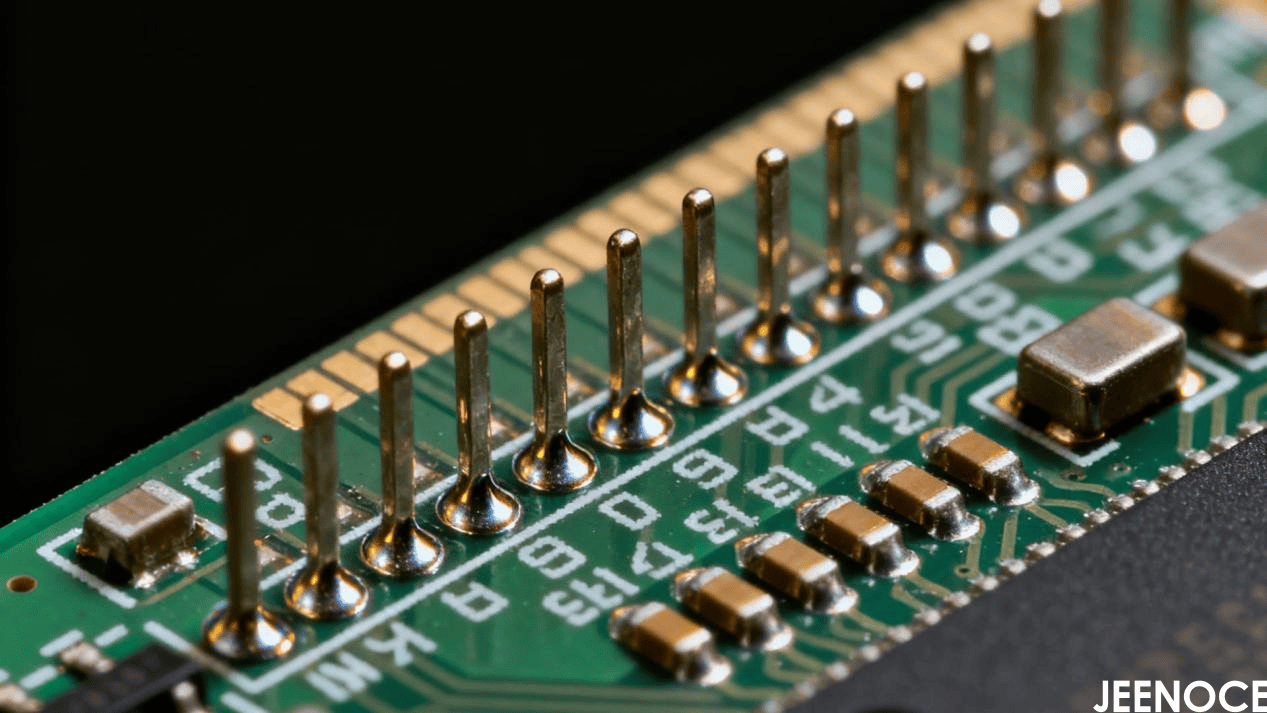

Reflow soldering is a crucial process in the assembly of electronic circuit boards, where solder paste is applied, components are placed, and then the board is heated to create permanent connections. Understanding the different types of reflow soldering machines and how they work can help manufacturers choose the most suitable system for their production needs.

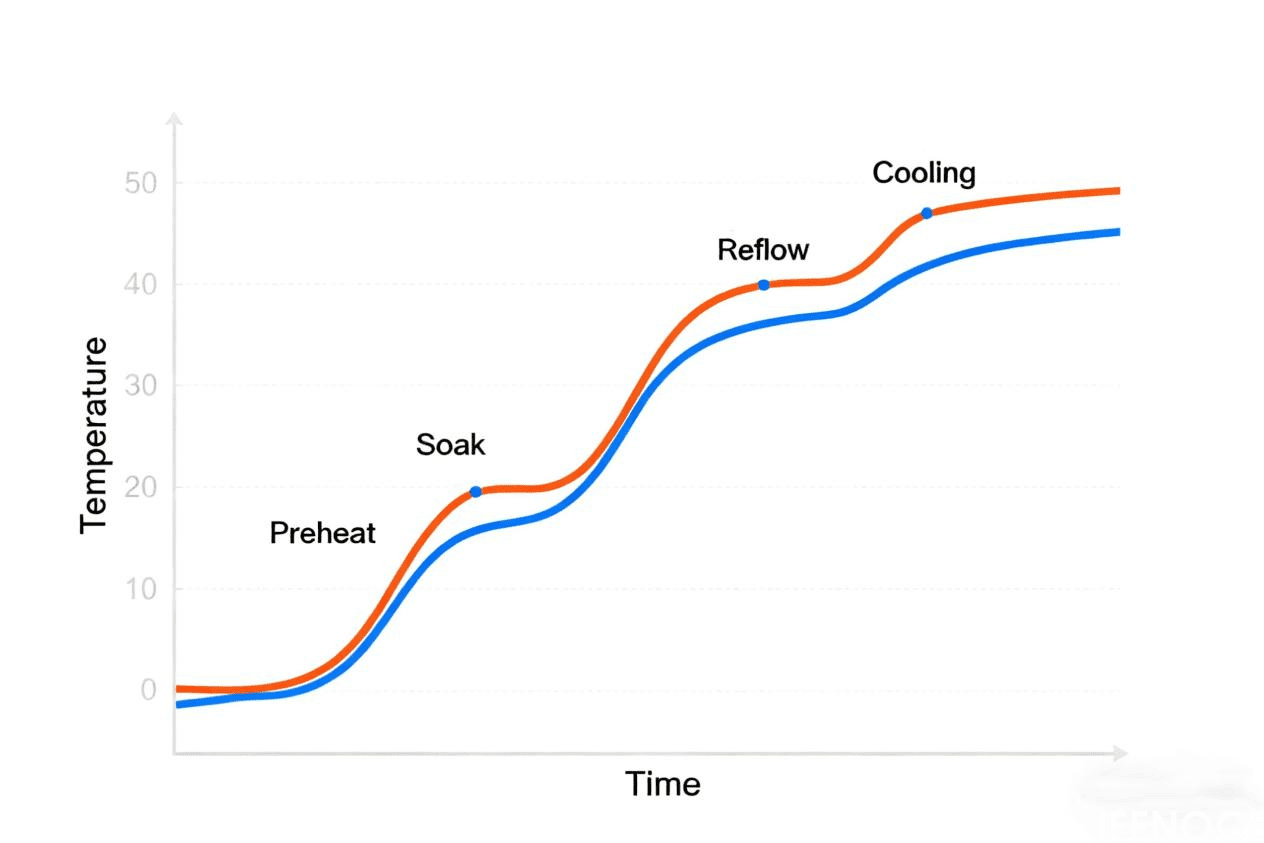

Reflow soldering involves the following steps:

Preheat: The board is gradually warmed to avoid thermal shock.

Soak: The temperature is stabilized to ensure even heat distribution.

Reflow: The paste is heated to its melting point, forming solid connections.

Cooling: The board cools slowly to solidify the connections.

These steps ensure high-quality solder joints and a reliable final product.

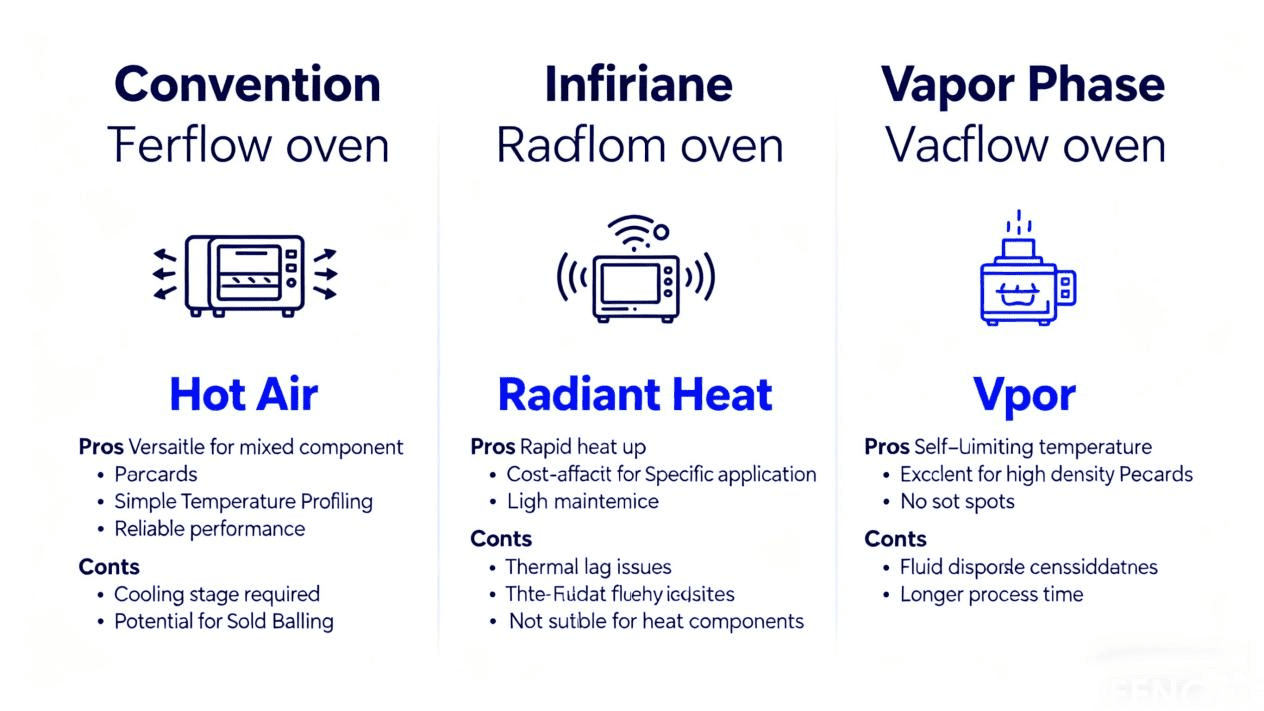

Each type of reflow soldering machine offers specific advantages depending on the production volume, product sensitivity, and soldering requirements.

Convection systems use hot air to evenly heat the board. This method is highly efficient for large-scale production.

Advantages:

Even heat distribution ensures consistent results.

Suitable for a variety of component sizes.

Ideal for lead-free soldering.

Best for: High-volume production of automotive, medical, and consumer electronics.

Infrared systems use radiant heat from infrared lamps to warm the board. These systems are fast and energy-efficient.

Advantages:

Quick heating time.

Energy-saving compared to convection systems.

Suitable for smaller production runs.

Caution: Parts may block infrared radiation, leading to uneven heating.

Best for: Prototyping, repairs, or working with lead-based solder.

Vapor phase systems heat the board using a specialized liquid that creates vapor. This ensures uniform temperature throughout the entire board, making it gentle on sensitive components.

Advantages:

Perfectly uniform heating, reducing the risk of overheating.

No oxygen exposure, preventing oxidation.

Ideal for sensitive components like those used in medical and aerospace industries.

Caution: The liquid used in vapor phase systems can be costly, and the process is slower than convection systems.

Best for: High-quality production where component protection is critical.

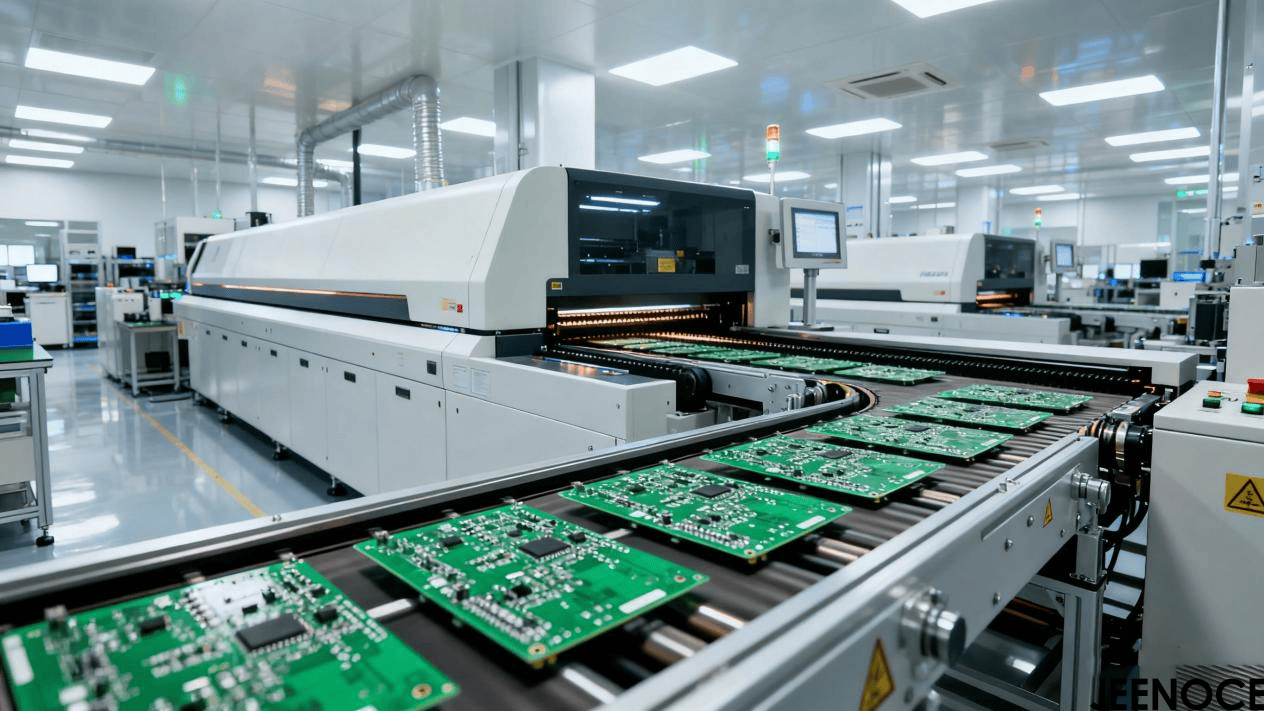

For manufacturers needing to produce large quantities of circuit boards efficiently, convection reflow soldering systems are the ideal choice. Their ability to handle high volumes and provide consistent results make them the go-to for mass production.

If your production involves delicate components or the use of lead-based solder, infrared or vapor phase systems may be a better fit. These systems provide the flexibility and protection required for sensitive applications.

The TSM series is known for its durability and high throughput, making it suitable for large factories with high-volume production lines.

The EPS RF 300 is a more flexible option, perfect for smaller shops or labs that need versatility without sacrificing performance.

System | Advantages | Limitations |

Convection | Even heating, high-volume capability, versatile | Can be slow for high-sensitivity components |

Infrared | Fast, energy-efficient, good for small batches | May have uneven heating due to component size |

Vapor Phase | Uniform heating, great for delicate components | Expensive fluid, slower process |

While convection ovens may have a higher upfront cost, they offer long-term savings due to their efficiency and ability to handle large batches.

Consider the size of your production facility and whether the reflow soldering system will scale as your production needs grow. Larger convection ovens might require more space than infrared or vapor phase systems.

Choosing the right reflow soldering system is vital for ensuring high-quality products and efficient production. For large-scale manufacturing, convection systems are often the best choice. For more delicate work or smaller volumes, infrared and vapor phase systems can provide the precision and protection needed.

At Jeenoce, we offer a range of reflow soldering solutions tailored to your production requirements. Whether you need high-volume efficiency or precision for sensitive components, our team can help guide you to the right system.

Explore our premium reflow soldering machines today and get a personalized quote by contacting us.

Message