Reflow soldering is a core process in Surface Mount Technology (SMT). It involves applying solder paste to a printed circuit board (PCB), placing components, and heating the assembly. This melts the solder, creating strong electrical and mechanical joints.

Reflow soldering enables high-density component placement on PCBs, which is critical for creating compact, efficient, and reliable modern electronics like smartphones, automotive systems, and aerospace technology.

Poor reflow profiles can cause defects like voids or weak joints. For example, defect rates in complex assemblies like BGAs can hit 15% if heating or cooling is uneven. Rework costs can account for 20-40% of manufacturing expenses in high-volume SMT lines.

With accurate thermal profiles, defect rates can decrease to 200-300 ppm for boards containing 900 parts and 3,000 solder joints.

JEENOCE’s focus on precision in smart manufacturing, using advanced technologies like MES integration and digital twins, ensures high-quality, efficient reflow soldering for reliable electronics in automotive, consumer, and aerospace industries.

With 15 years of expertise, we help reduce defects and boost throughput.

How It Works

IR reflow uses thermal radiation to heat solder paste. Infrared heaters emit waves (0.7μm–1mm) that are absorbed by the PCB, turning energy into heat. This melts the solder, forming joints.

Setup

IR ovens have multiple heating zones with quartz, ceramic, or halogen heaters. PCBs move through these zones on a heat-resistant conveyor belt, like PTFE fiberglass cloth.

Key Features

Fast Heating: Directly heats solder paste, cutting soldering time.

Cost-Effective: Lower equipment costs make it ideal for high-volume production.

Challenge: Different PCB materials absorb IR differently. For example, black components may overheat, while silver leads may stay too cool, causing defects.

Applications

Perfect for high-volume consumer electronics, such as smartphones and appliances.

JEENOCE Tip: Add hot air circulation to IR ovens to reduce uneven heating. Our MES-integrated systems adjust wavelengths in real-time, cutting defect rates by 20% in dense assemblies.

How It Works

Convection reflow uses hot air to transfer heat. Forced convection, common in industrial settings, uses fans to circulate air. This heats the PCB evenly, melting solder paste.

Setup

Ovens have multiple temperature-controlled zones. Fans (axial or tangential) ensure precise heat distribution. Tangential fans create vortices for better zone control.

Key Features

Uniform Heating: Forced convection ensures even temperatures, reducing defects like solder balling.

Nitrogen Option: Using nitrogen prevents oxidation, improving joint quality for aerospace PCBs.

Applications

Widely used in automotive and industrial electronics.

JEENOCE Solution: JEENOCE’s MES-integrated systems deliver precise zone control and nitrogen support, ensuring reliable solder joints that enhance quality and efficiency in electronics manufacturing for automotive, aerospace, and consumer applications.

How It Works

This method combines IR’s rapid heating with hot air’s even distribution. IR heaters quickly heat the PCB, while hot air ensures uniform temperatures.

Setup

Ovens use IR panels and air nozzles for flexible zoning and customized thermal profiles.

Key Features

Energy Efficiency: Hybrid reflow soldering’s energy-efficient blend of fast heating and uniform temperature distribution delivers peak performance, ensuring high-quality, cost-effective production for modern electronics like automotive ECUs and smartphones.

Improved Yield: Achieves 99.2% BGA joint yield in automotive ECU production (JEENOCE-HARMAN collaboration).

Applications

Ideal for automotive electronics requiring reliable BGA joints.

How It Works

Vapor phase uses eco-friendly fluids (e.g., Galden®) that vaporize and condense on the PCB. This provides uniform heating at the fluid’s boiling point.

Setup

A sealed chamber heats the fluid. PCBs sit on a tray, and sensors monitor temperature. Fans cool the vapor post-soldering.

Key Features

High Precision: Ensures consistent temperature control within a range of ±1.5°C, ideal for essential applications.

Reliable Joints: Ensures consistent soldering for high-reliability needs.

Applications

Used in aerospace and medical devices where precision is critical.

Practical Tip:To ensure you meet environmental guidelines while achieving high-quality solder joints, think about using eco-friendly fluids such as Galden® for vapor phase soldering.

How It Works

Laser reflow soldering delivers precise, localized heat to melt solder paste in targeted areas, making it ideal for soldering tiny components in high-density, high-reliability electronics like 5G base stations, LEDs, and medical devices.

Setup

Systems include a laser source, optical system, and precise positioning controls.

Key Features

Micro-Precision: Supports 0.2mm pitch soldering for small components.

Cost Savings: Reduces rework costs by 40% compared to replacing $5,000 RF modules.

Applications

Great for LED chip soldering and 5G base station board rework (e.g., 01005 components).

How It Works

Hot gas is directed onto the PCB through nozzles, melting solder paste. It’s ideal for non-contact soldering.

Setup

Systems use a gas-heating unit with adjustable nozzles for precise heating.

Key Features

Non-Contact: Prevents damage to flexible PCBs, with a 0.1% damage rate (OSRAM LED data).

Flexible: Perfect for delicate substrates like wearables.

Applications

Used for flexible PCBs and LED modules in automotive and wearable tech.

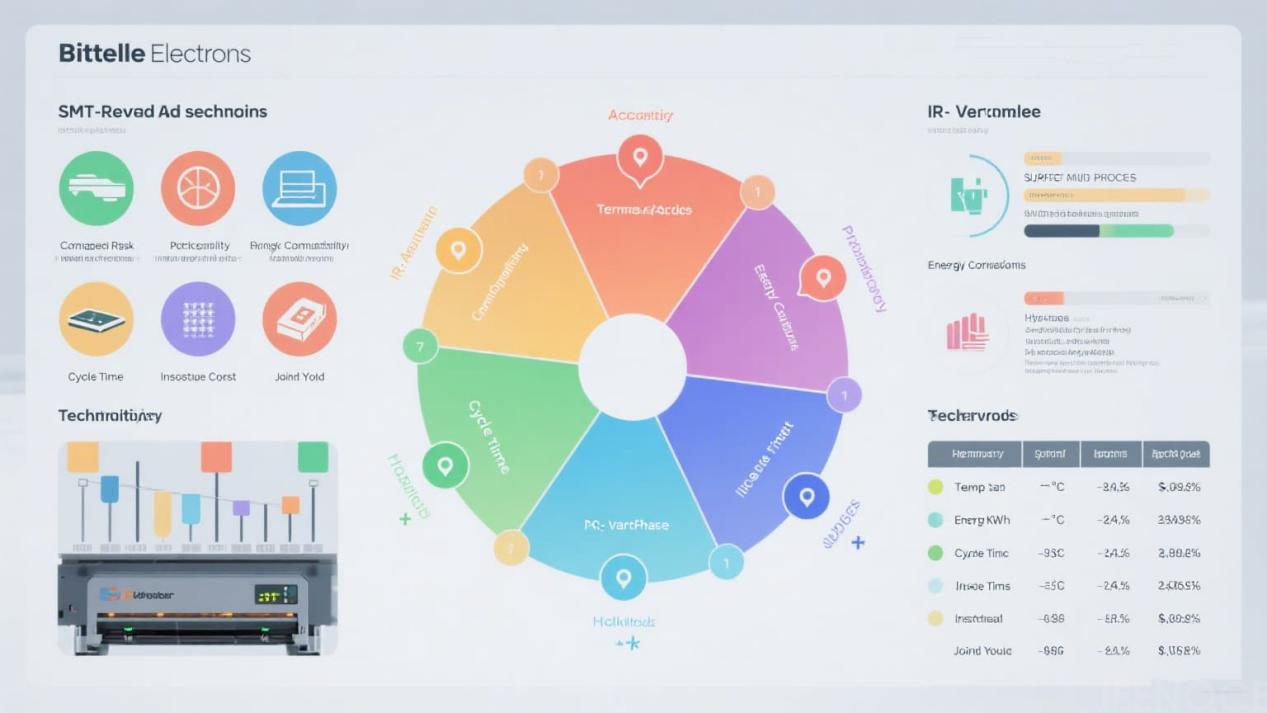

Here’s a quick comparison of reflow soldering methods:

Parameter | IR | Vapor Phase | Laser | Convection | Hybrid | Hot Gas |

Temp. Accuracy (±°C) | 5 | 1.5 | 0.3 | 2 | 3 | 4 |

Component Damage Risk | Medium | Low | Very Low | Low | Medium | Low |

PCB Compatibility | Rigid | All Types | Micro | Rigid/Flex | Rigid | Flex |

Energy (kWh) | 35 | 28 | 8* | 30 | 27 | 5* |

Cycle Time (sec) | 240 | 300 | Custom | 260 | 220 | 45* |

Investment ($) | 50K | 120K | 200K+ | 70K | 90K | 25K |

Joint Yield (%) | 98.2 | 99.5 | 99.9 | 99.1 | 99.3 | 98.8 |

*Localized processing only. Data: Bittele Electronics, JEENOCE testing.

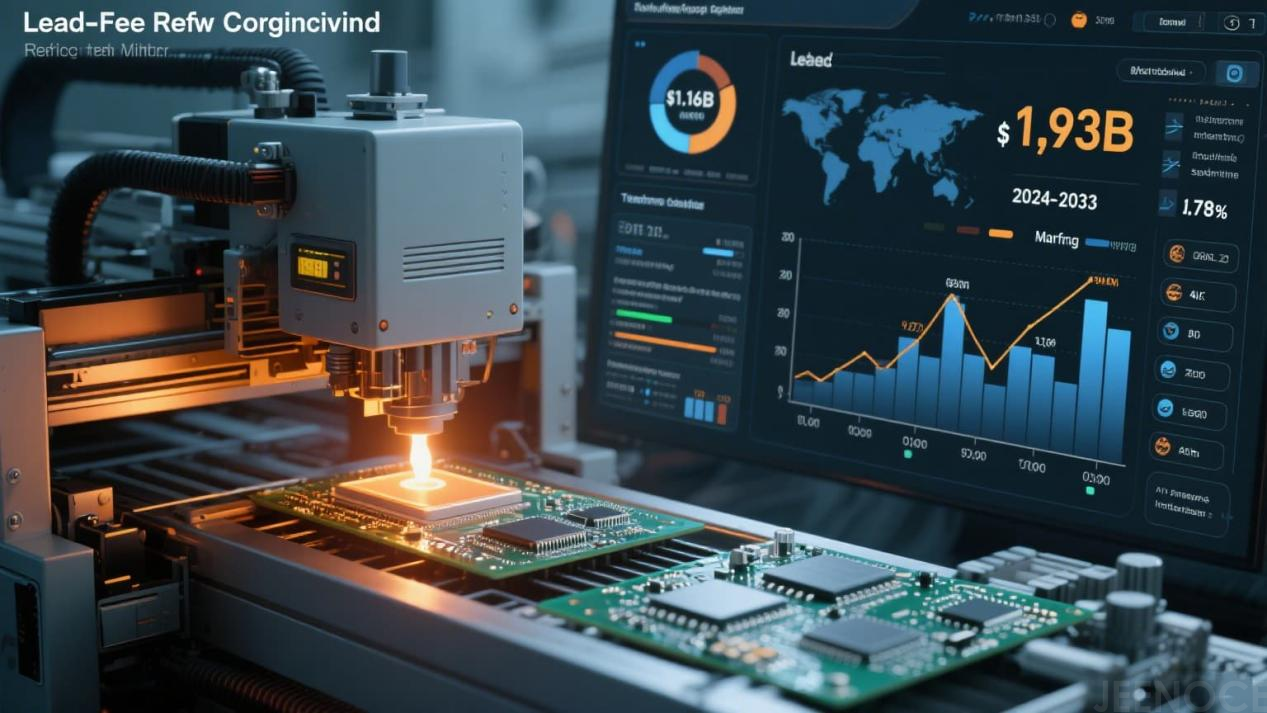

The reflow soldering market is growing fast, from $1.2 billion in 2024 to $2.0 billion by 2033 (CAGR of 5-7%). Key trends include:

Lead-Free Compliance: Adjust thermal profiles with extended soak times to prevent defects like poor wetting.

Digital Twin Technology: JEENOCE’s Digital Factory System leverages virtual simulations to cut reflow soldering profile optimization time by 65%, enabling faster, cost-effective production of reliable electronics for industries like automotive, consumer, and aerospace.

Predictive Maintenance: Our 24/7 network, using CPK data from 2,000+ machines, reduces downtime by 40%.

Hybrid Line ROI: Modular retrofits boost throughput by 37%, with a 14-month payback (Neways automotive case).

JEENOCE Proposal: Our modular line retrofits have delivered 37% efficiency gains for automotive clients, integrating reflow soldering machines with smart controls.

In reflow soldering, the main selection criteria focus on joint quality rather than product type, throughput, or budget.

This method ensures that Surface Mount Technology (SMT) assemblies remain reliable over the long term.

Hybrid reflow soldering’s expansion, driven by its efficiency and versatility, contributes to the reflow soldering market’s projected 5-6% CAGR growth from 2024 to 2033, meeting the demand for compact, reliable electronics in automotive, consumer, and aerospace industries.

Hybrid reflow soldering’s rise, driven by its energy-saving efficiency and flexibility in handling diverse assemblies, supports cost-effective, high-quality production.

JEENOCE provides complete SMT solution, backed by a team of more than 10 R&D engineers and PLM/MES integration, to develop production lines that are prepared for the future.

Contact us for a Free SMT Line Assessment Report to optimize your yield and ROI!

Message