Achieving zero-defect manufacturing isn’t just wishful thinking anymore—it’s becoming a reality within 90 days, thanks to automated assembly lines powered by AI and real-time feedback. At the heart of this transformation is Automated Optical Inspection (AOI) combined with Statistical Process Control (SPC) automation, two technology pillars that detect defects with unmatched speed and accuracy.

AOI uses AI vision inspection to scan every component and solder joint instantly, catching errors that humans can easily miss. Meanwhile, SPC automation applies data-driven analysis to monitor and control the process—adjusting production “recipes” in real time based on defect patterns. This closed-loop quality control approach doesn’t just catch issues; it prevents them from spreading.

The result? Continuous, automated quality assurance that drives scrap rates down, boosts yield, and delivers a consistent zero-defect output in just three months. With real-time defect detection feeding back into the system, assembly lines evolve dynamically, making manual rework and delayed inspections a thing of the past.

Achieving zero defects on automated assembly lines isn’t luck—it’s built on a solid framework. Here’s how we make it happen through four key pillars:

Using AI-powered 3D Automated Optical Inspection (AOI), we catch defects faster and more accurately. This system provides clear, actionable metrics for every station and even links alerts directly to specific operators’ phones—so problems get noticed and fixed immediately.

Statistical Process Control (SPC) isn’t just about spotting trends; our closed-loop setup automatically adjusts machine recipes in real time. If a defect pattern starts forming, the system corrects within seconds, preventing issues before they happen.

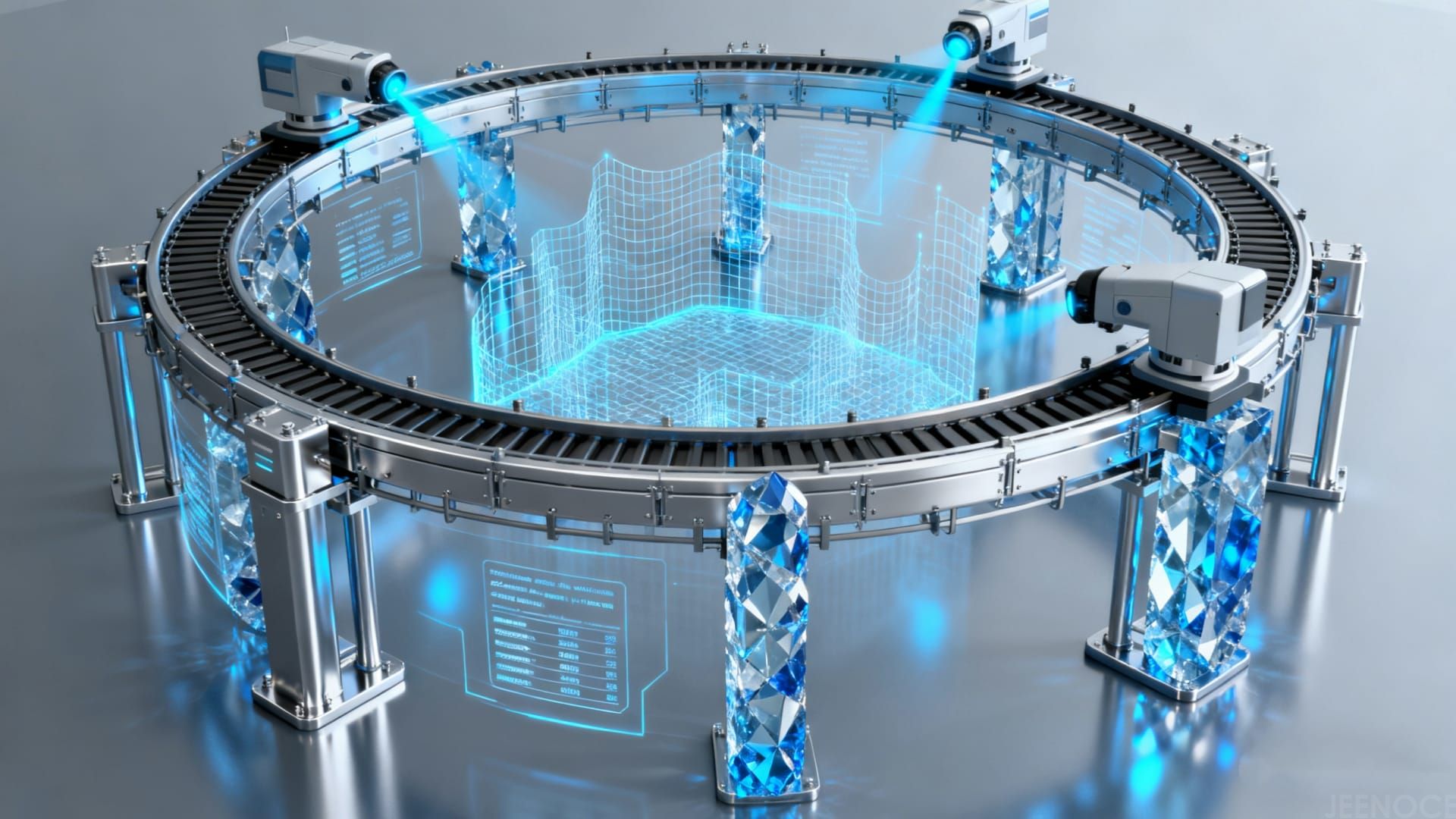

We create a digital twin of your assembly line—a virtual copy that predicts defects up to 72 hours before they appear on the floor. This early warning lets teams act proactively, reducing downtime and scrap.

Operators get an app that shows real-time line status with simple red/green lights. This instant feedback keeps everyone in sync and focused on maintaining zero defects, without waiting for reports or meetings.

Together, these four pillars combine AI inspection, proactive control, predictive insights, and operator engagement to redefine quality in manufacturing.

Here’s how real-time feedback and AI-powered quality control are making zero defects a reality in the field:

Case A: Automotive Radar-Loop Systems

Automated optical inspection (AOI) with AI vision tools helped this line cut field returns drastically. Real-time defect detection and closed-loop quality control caught issues early, preventing costly recalls and boosting customer trust.

Case B: Medical Wearables

Using digital twins and SPC recipe updates, a medical device manufacturer passed their FDA audit on the very first inspection. The operator app’s real-time line status ensured no faulty units slipped through, which is critical in healthcare.

Case C: Consumer Drone Assembly

By integrating AI-based defect detection with a smart factory KPI dashboard, this drone line cut scrap costs by $840.000 annually. The automation plant’s predictive maintenance and inline PCB inspection caught problems 72 hours ahead, keeping yield high and costs low.

These examples show how automated assembly lines with real-time feedback and AI are redefining quality control across industries, delivering measurable savings and consistent zero-defect manufacturing.

Here’s how you can hit zero defects in just 90 days with our step-by-step plan:

Start by assessing your current assembly line yield.

Set up the automated optical inspection (AOI) system to capture defect data from day one.

Identify key problem areas using real-time defect detection tools.

Integrate AI-powered vision inspection on your surface-mount technology (SMT) lines without halting production.

Train AI models with historical and fresh data for sharper defect detection.

Begin closed-loop quality control by triggering immediate feedback when defects pop up.

Launch the full closed-loop SPC (Statistical Process Control) system for PCBs, enabling recipe corrections in seconds.

Monitor production through a smart factory KPI dashboard showing real-time line status and defect trends.

Empower operators with a live app displaying red/green line status for quick action.

Download our PDF roadmap to get detailed checklists and timelines that help you stay on track toward zero-defect manufacturing. This plan fits perfectly for manufacturers looking for practical steps and measurable results fast.

Our built-in ROI calculator makes it simple to understand the financial impact of upgrading to an automated assembly line with real-time defect detection. Just plug in your current inspection line throughput, labor costs, and quality control metrics, and you get a clear picture of what to expect.

Inputs:

Number of units your line processes daily

Labor hours dedicated to inspection and quality control

Current defect rates and scrap costs

Architecture Overview:

The calculator models how integrating AI vision inspection, closed-loop quality control, and automated optical inspection improve yield and cut rework time.

Output:

Payback Period: See your investment return in as little as 8 months

Year One Savings: Potential to save up to $1.7 million by reducing defects and streamlining operations

This tool offers a straightforward, data-driven snapshot tailored for manufacturers looking to justify automation investments without the guesswork. It’s a trusted way to bring zero-defect manufacturing from concept to reality while showing real financial benefits upfront.

When it comes to automated assembly lines and zero-defect manufacturing, we hear a few common concerns. Let’s tackle them quickly and clearly.

Upfront cost is high? Leasing options make advanced AI vision inspection and automated optical inspection affordable, spreading payments to fit your budget.

Is it worth the investment?With our ROI calculator, many East Asian and Southeast Asian manufacturers see payback in under 8 months and savings in the millions within the first year.

Older systems can slow down real-time defect detection and closed-loop quality control.

Our solution works seamlessly alongside existing equipment, using OPC-UA manual gateways or upgrading to inline automation.

This means little downtime and fast deployment while boosting your automated assembly line’s performance.

| Feature | OPC-UA Manual Gateway | Inline Automation |

|---|---|---|

| Integration Speed | Medium (Requires manual setup) | Fast (Plug-and-play) |

| Real-Time Data Feedback | Limited | Full real-time feedback |

| Latency | Higher Latency | Near-zero Latency |

| Scalability | Moderate | High |

| Cost | Lower Initial Cost | Higher Initial Cost |

| Best For | Legacy Systems and Retrofits | New Lines and Modernization Projects |

Choosing the right approach depends on your current line’s setup and long-term goals. Either way, real-time feedback in assembly lines means zero-defect manufacturing is now within easy reach for manufacturers.

Ready to see how zero-defect manufacturing really works? Our virtual IPC line walk gives you a front-row seat to the automated assembly process, without leaving your desk. We walk you through every step, showing you real-time system screenshares and guiding you with a detailed script review.

During the demo, you’ll get a clear view of how the real-time feedback loop operates and how the software adjusts instantly to keep quality on track. Plus, we’ll take you through the Zero-Defect Risk Heat Map—a visual tool that highlights where potential flaws might appear on your line before they happen.

This hands-on session helps you understand how automated optical inspection (AOI), AI defect detection, and closed-loop SPC work together to stop defects in their tracks. It’s a no-fluff opportunity to see data-driven quality control in action and build confidence in your zero-defect roadmap.

Live screenshare of your IPC line in action

Step-by-step script walk-through of inspection and recipe correction

Interactive overview of risk heat maps for proactive defect prevention

Q&A on integrating real-time feedback and AI-powered quality control

This is your chance to experience zero-defect thinking firsthand and explore how these tools fit your current production—setting the stage for a smoother, smarter manufacturing future.

Even the best automated assembly lines hit snags. Here are the usual trouble spots—and how to fix them fast:

Data Silos Skyrocketing Yield Loss

When data lives in separate pockets, your quality control suffers. The solution? A unified MQTT pipeline that connects all machines and systems seamlessly. This lets you spot defects early and tackle issues before they snowball.

Over-Tuned AI Causing False Positives

AI is powerful but can flag too many false alarms if pushed too hard. Using an active learning loop helps the system adjust smartly over time, reducing unnecessary stops and keeping production flowing.

Operator Resistance to New Tech

Changes on the line can meet pushback. The trick is HMI gamification, turning operator interfaces into interactive, easy-to-use dashboards. This boosts engagement, leading to a 98% adoption rate—making real-time feedback part of daily work instead of a hassle.

Avoiding these pitfalls means smoother operations, fewer defects, and a quicker path to zero-defect manufacturing.

Automated assembly lines don’t just stop at improving quality on the floor—they extend their impact across the entire supply chain. One of the game-changers here is serialized QR etching combined with a blockchain ledger. This setup gives every product a secure, traceable identity that can be tracked from start to finish with full transparency.

Why does this matter? When a defect or issue pops up, companies can trigger a one-click recall containment in just 11 minutes—massively faster than the industry average of 36 hours. This speed helps prevent costly downtime, protects brand reputation, and keeps customers safe.

By tying quality control directly into supply chain traceability, you’re not only cutting risk but also building a smarter, more reliable manufacturing ecosystem. This level of transparency is becoming essential for manufacturers focused on compliance, safety, and meeting customer expectations in real time.

Staying ahead means adopting the latest tech that keeps your automated assembly line flexible and efficient. Here’s how 5G, digital thread, and cobot integration make that happen:

5G Edge Nodes Reduce Latency to 1 ms

Faster data flow means real-time defect detection and instant feedback without delays. This ultra-low latency keeps closed-loop quality control systems sharp and responsive, boosting your zero-defect manufacturing goals.

Cobots Auto-Load Reels Based on AI Predictions

Smart cobots watch for material depletion and automatically reload reels just before stocks run out. This cuts downtime and keeps your line running smoothly, saving you labor costs and avoiding last-minute rushes.

2026 Vision Roadmap

Our forward-looking plan tightens the link between AI-powered defect detection, digital twins, and network upgrades. From seamless supply chain traceability using blockchain to full integration of smart operator apps and 5G-enabled communication—this roadmap maps the future of automated plant success in East Asia and Southeast Asia.

By investing in these cutting-edge technologies now, you’re not only improving today’s yield but also setting your assembly line up for growth and adaptability in a rapidly evolving market.

Message