What are the common defects in semiconductor packaging, and why do they matter? In packages like flip-chip, BGA, and CSP, defects such as voids, delaminations, cracks, and disbonds are critical concerns. These flaws can severely impact the reliability and performance of chips. For example, voids and delaminations weaken mechanical bonds, leading to thermal failures or the notorious popcorn effect—where moisture trapped inside expands rapidly during soldering, causing package cracking.

Detecting these defects early is essential because they can cause device failures, reduce yield, and increase costs. Unfortunately, traditional inspection methods face challenges. Optical and X-ray inspections struggle with opaque multi-layer structures common in advanced packaging, limiting their effectiveness. Manual interpretation of Scanning Acoustic Microscopy (SAM) data is also problematic, as it can be subjective and prone to error, especially in high-volume production environments.

In the context of Moore’s Law extensions and the growing complexity of semiconductor devices, these challenges are more pronounced. With trends moving toward High Bandwidth Memory (HBM) and System-in-Package (SiP) solutions by 2025. reliable and scalable defect detection methods are vital.

That’s why Scanning Acoustic Microscopy (SAM) is rapidly becoming the gold standard non-destructive testing (NDT) tool for semiconductor packaging. SAM’s ability to penetrate layers and detect internal defects provides a clear advantage. When combined with automated analysis, SAM helps overcome manual interpretation limitations, offering faster, more accurate, and consistent defect recognition that keeps pace with modern manufacturing demands.

Scanning Acoustic Microscopy (SAM) uses sound waves—usually in the 15 to 200 MHz range—to look inside semiconductor packages without damaging them. The core idea is measuring how sound bounces back when it hits different materials. This relies on acoustic impedance contrasts, which means materials with different densities reflect sound differently. SAM typically uses several imaging modes:

A-scan (depth profile)

B-scan (cross-sectional image)

C-scan (planar, 2D map of defects)

One of the biggest advantages of C-mode SAM is its ability to deliver detailed images with less than 50-micron resolution. It’s a non-contact, immersion method—meaning parts are scanned while submerged in a liquid couplant, preserving delicate structures. Because SAM captures real-time volumetric data, it supports 3D reconstruction, helping engineers visualize voids, delaminations, and cracks inside multi-layer packages.

But there are challenges. Noise can come from fiber layers and interfaces inside packages, making defect signals harder to detect. Focus sensitivity limits can also impact scans in nm-scale thin stacks common in advanced IC packaging. Throughput is another bottleneck—high-volume fabs need faster scanning speeds without losing resolution.

A practical SAM setup includes:

High-frequency transducers suited for the package type

Proper couplants for consistent sound transmission

Software that handles raw waveform analysis and converts data into usable images

For factories moving towards automation, SAM systems can integrate inline with production lines. Automation interfaces allow seamless data flow and real-time defect recognition, enabling faster decision-making and improved yield in semiconductor packaging.

We’ve moved from relying on operators’ experience to using AI-powered models for automated defect recognition in semiconductor packaging. Machine learning techniques like SVM (Support Vector Machine), GRNN (General Regression Neural Networks), and deep learning models like ResNet now achieve 95%+ accuracy in spotting defects.

| Technique | Purpose | Result |

|---|---|---|

| Wavelet Transforms | Enhance signal-to-noise ratio (SNR) | Clearer signals for detection |

| PCA (Principal Component Analysis) | Extract key features from data | Stable classification at 20 microns |

| Deep Learning (ResNet) | Classify sub-resolution defects | Detects defects 10 microns and smaller |

Data Acquisition: Automated scanners collect raw SAM waveform data.

Signal Processing: Filters and wavelet transforms clean the signal.

Pattern Recognition: AI models analyze data for defect patterns.

Alerting: Instant notifications for detected defects.

MES Integration: Seamless connection with manufacturing execution systems for inline control.

Faster Inspections: Quick turnaround on defect detection.

Reduced False Positives: More accurate results reduce unnecessary rework.

Scalable Inline Testing: Enables 100% inspection in high-volume fabs without slowing production.

Physics-informed neural networks combining material physics with AI.

Hybrid SAM-X-ray systems to target defects in advanced semiconductor nodes beyond 5nm.

Automation is reshaping how we spot voids, delaminations, and cracks through scanning acoustic microscopy, making the process faster, more reliable, and ready for the future of semiconductor packaging.

Automated defect recognition using Scanning Acoustic Microscopy (SAM) is proving powerful in real-world semiconductor packaging. For example, flip-chip solder bump inspection benefits hugely from AI models like GRNN, which can identify missing or open bumps in dense arrays with 98 percent accuracy. This helps avoid failures that might otherwise slip past manual checks.

In High Bandwidth Memory (HBM) modules, advanced signal filtering techniques detect microcracks early, preventing yield loss and costly rework. This kind of microcrack detection is crucial for maintaining package reliability under thermal and mechanical stress.

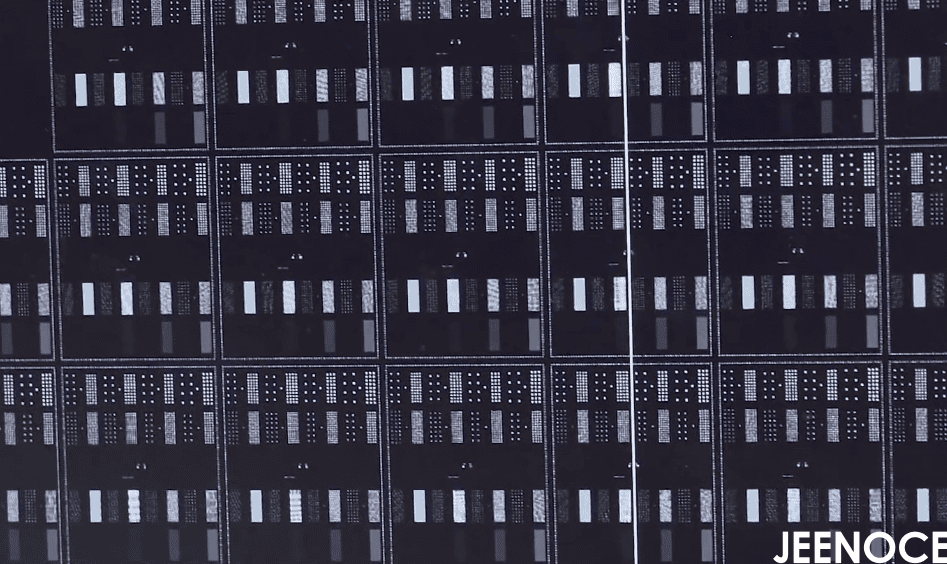

A standout case is Jeenoce’s integration of automated SAM systems into SMT production lines. By adopting inline SAM with AI-driven defect recognition, they achieved a 30 percent reduction in defect rates. This integration demonstrates how combining SAM technology with smart manufacturing boosts yield and efficiency in real factory environments.

Beyond semiconductors, automated SAM defect detection finds value across industries, including power electronics using silver sintering (Ag-sintering) and medical device probes where reliability is critical. These cross-industry successes highlight SAM’s versatility for nondestructive testing (NDT) in multilayer, opaque packages.

To measure impact, companies use ROI calculators tracking time saved against costs of implementation. Faster inspections, fewer false positives, and higher throughput translate into clear bottom-line benefits. Automated SAM offers a smart, scalable solution for manufacturers aiming to stay competitive in today’s complex packaging landscape.

Getting automated Scanning Acoustic Microscopy (SAM) up and running smoothly in your production line takes careful planning and the right approach. Here’s what works best:

Evaluate your current process: Identify key pain points where defects slip through or manual inspection slows production.

Choose the right SAM system: Look for hardware that fits your package types—flip-chip, BGA, CSP—and supports your throughput needs. Consider transducers with the right frequency range for your materials to maximize resolution and penetration.

Plan couplant handling: Use effective couplants for immersion testing that won’t interfere with your assembly line speed or contaminate electronics.

Gather a diverse set of defect samples from your own production, covering voids, delaminations, cracks, and disbonds.

Train and fine-tune machine learning models (like ResNet or GRNN) on this real-world data to boost defect recognition accuracy for your unique processes.

Continuously update models with new defect instances to maintain performance over time.

Adjust acoustic frequencies to suit different layers and materials for clearer signals—higher frequencies for thin layers, lower for deeper scanning.

Tailor post-processing algorithms to reduce noise caused by fibers or multi-layer stacks common in advanced packages.

Implement signal processing steps such as wavelet transforms and PCA to enhance image clarity and suppress artifacts.

Use software filters to minimize false positives from benign anomalies.

Ensure your automated SAM system aligns with industry standards like JEDEC for consistent quality benchmarks.

Document your process and results for audits and traceability.

Calibration problems: Regularly calibrate your SAM equipment to prevent drift in detection accuracy.

Data silos: Integrate your SAM system with Manufacturing Execution Systems (MES) to avoid isolated data pools and enable real-time decision-making.

Overfitting AI models: Avoid training models on limited data sets; diverse and updated datasets are key.

Invest in scalable architectures that can handle the complexity of 5nm and smaller nodes.

Incorporate edge AI solutions for real-time processing right on the production line, reducing delays and enabling instant feedback.

Plan for seamless integration with other inspection methods like X-ray for comprehensive quality assurance.

Following these best practices ensures your automated SAM implementation delivers faster, more reliable defect detection with less manual effort—keeping your semiconductor packaging quality ahead in the competitive East and Southeast Asian markets.

Message