Essential Ultrasonic Scanning Microscope for the High-End Semiconductor Industry

Ultrasonic scanning microscopes are widely used in semiconductors, materials science, medicine, pharmaceuticals, and industrial fields.

These microscopes utilize principles similar to the echolocation techniques used by bats and dolphins, enabling non-destructive detection of defects such as grain boundaries, cracks, delamination, voids, bubbles, and contaminants.

Ultrasonic scanning microscopes play a crucial role in the global high-precision inspection market, particularly for semiconductor integrated circuits.

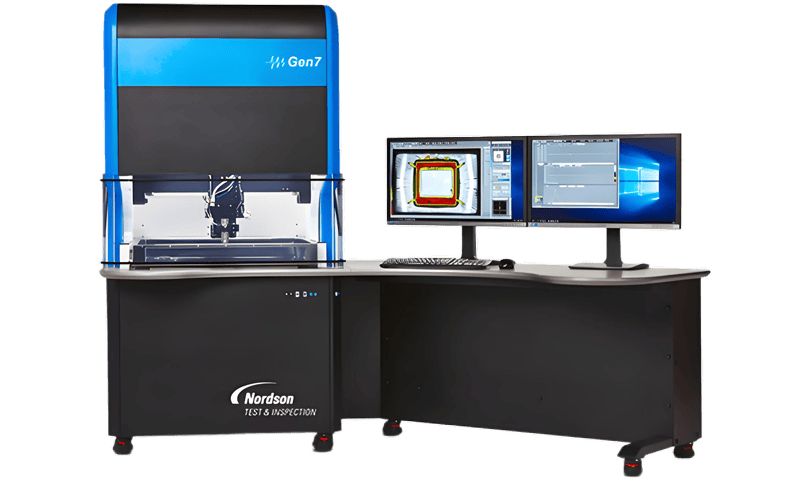

To meet growing demand in the semiconductor industry, Jeenoce offers the world's most advanced ultrasonic scanning equipment, helping companies tackle production challenges throughout wafer manufacturing.