Process control method for reflow soldering quality of circuit boards

Release time:2024-07-24Publisher:Jeenoce

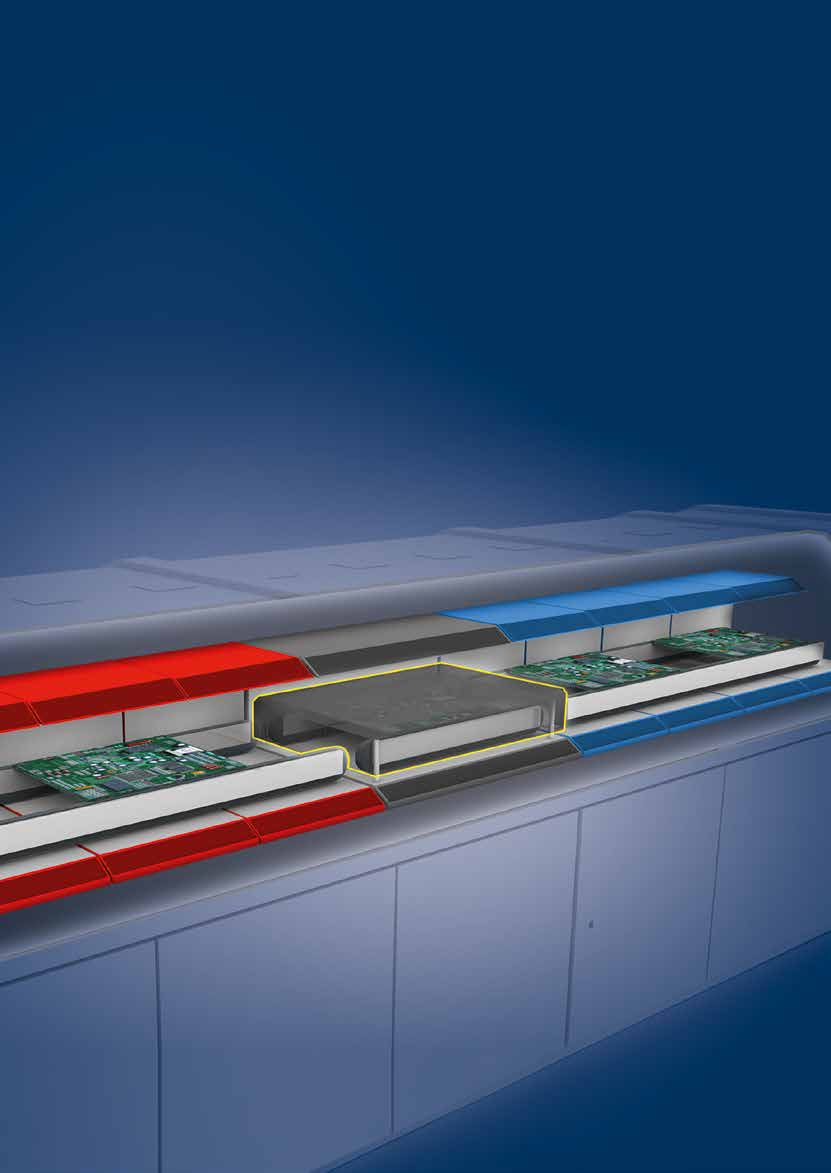

The advantages of the reflow soldering process for circuit boards are that the temperature is easier to control, oxidation can be avoided during the soldering process, and the manufacturing cost is also easier to control. However, the quality process of reflow soldering must be well controlled, otherwise batches of defective products may occur. JEENOCE shares here the quality process control method for circuit board reflow soldering.

1. It is necessary to establish a scientific reflow soldering temperature curve and regularly conduct real-time temperature curve testing.

2. Reflow soldering should be carried out according to the soldering direction during PCB design.

During the reflow soldering process, it is necessary to prevent vibration of the conveyor belt.

4. The reflow soldering effect of the first printed circuit board must be checked.

5. Whether the reflow soldering is sufficient, whether the solder joint surface is smooth, whether the solder joint shape is crescent shaped, the situation of solder balls and residues, and the situation of continuous soldering and virtual soldering. Also, check the color changes on the surface of the PCB. Adjust the temperature curve based on the inspection results. Regularly check the welding quality during the entire production process.

6. Regularly maintain the reflow soldering machine. Due to the long-term operation of the machine, organic or inorganic pollutants such as solidified rosin may adhere. In order to prevent secondary pollution of the PCB and ensure the smooth implementation of the process, regular maintenance and cleaning are necessary.