Application of X-RAY Inspection for PCBA Circuit Boards

Release time:2024-07-24Publisher:Jeenoce

With the development of high-density packaging technology, the PCBA industry has also brought new challenges to testing technology. In order to cope with these new challenges, many technologies are constantly emerging. X-RAY testing equipment, as one of the mainstream non-destructive testing equipment, can effectively detect the quality of BGA soldering and assembly. Currently, many production-oriented industries have adopted X-RAY testing equipment to better inspect the internal structure of products for defects and deficiencies.

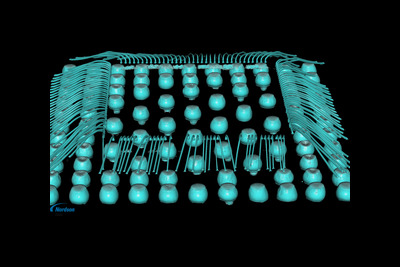

In terms of the PCBA industry, the quality of BGA testing is receiving increasing attention from enterprises, especially with the miniaturization of PCBA packaging. While products are becoming more and more exquisite, it also brings more obstacles to assembly for processing personnel. For example, products are too small and processed too finely, and there are certain difficulties in operation. In addition, after the plug-in is soldered on the PCBA board, the soldering situation of the product cannot be seen from the appearance due to the pins inside. Therefore, X-RAY equipment is widely used in the market to detect solder joints, check for abnormalities such as solder bubbles, virtual soldering, and leakage. In a sense, X-RAY testing technology is a necessary means to ensure the quality of electronic assembly.

X-RAY uses an X-ray emission source as the base point, and the X-rays emitted by strong pressure electrons hitting a metal target penetrate the sample. The detector absorbs and transmits the transmitted light to the display, and technical analysts can intuitively view the image files on the display according to their own needs.