SMT reflow soldering technical indicators

Release time:2024-07-23Publisher:Jeenoce

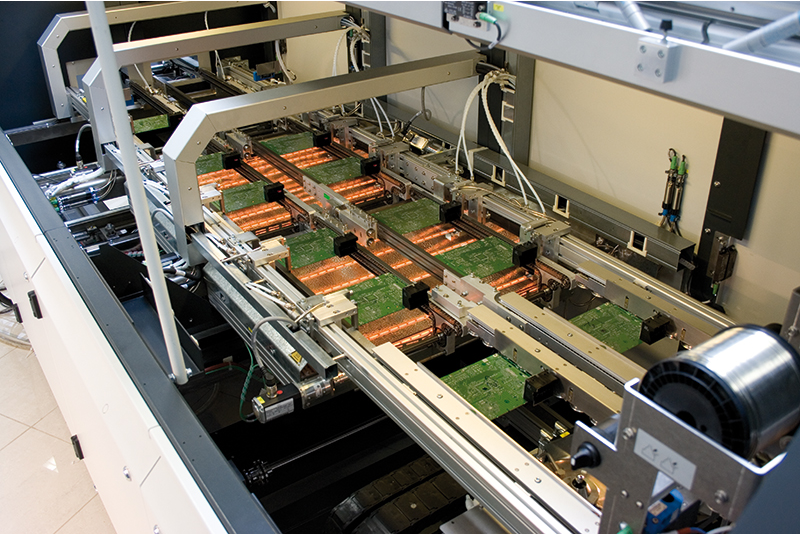

SMT reflow soldering has many technical indicators, such as temperature control accuracy, transverse temperature difference of the conveyor belt, maximum heating temperature, number and length of heating zones, conveyor belt width, cooling efficiency, etc. These detailed technical indicators can ensure that there are no errors during the SMT reflow soldering stage, providing customers with high-quality product services. JEENOCE shares SMT reflow soldering quality process technology indicators.

1. The temperature control accuracy of SMT reflow soldering should reach ± 0.1~0.2 ℃;

2. The transverse temperature difference of the transmission belt for SMT reflow soldering is traditionally required to be below ± 5 ℃, while for lead-free soldering it is required to be below ± 2 ℃.

3. Temperature curve testing function: If the SMT processing equipment does not have this configuration, a temperature curve collector should be purchased externally

4. The maximum heating temperature for reflow soldering in SMT is 350-400 ℃ for lead-free solder or metal substrates

5. Number and length of heating zones: The longer the heating zone length and the more heating zones there are, the easier it is to adjust and control the temperature curve. For lead-free soldering, a temperature zone of 7 or more should be selected.

6. The width of the reflow soldering conveyor belt should be determined based on the maximum and minimum PCB sizes.

7. The cooling efficiency of SMT reflow soldering should be determined based on the complexity and reliability requirements of PCBA products. For products with complex and high reliability requirements, high cooling efficiency should be selected.