How to distinguish weld bubbles in X-ray weld detection

Release time:2024-07-23Publisher:Jeenoce

The results of traditional X-ray weld seam bubble detection can be used as the basis for weld defect analysis and quality judgment. The commonly used X-ray detection method requires experienced inspectors to operate, and its workload is large. The accuracy of the detection results also largely depends on the technical level of the inspector, which has a certain lag compared to the X-ray detection equipment that displays and tests the area of weld seam bubbles in real-time on computers.

In recent years, domestic and foreign scientific and technological workers have implanted modern technologies such as computer technology, image application technology, and pattern recognition into X-ray inspection machines, making considerable progress.

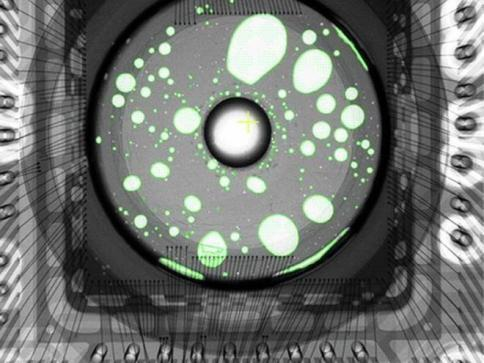

However, in actual weld seam bubble detection projects, the real-time detection image generated by X-rays is a 2D grayscale image, and the grayscale value of the bubbles is very close to that of the steel pipe. This requires technical analysis to determine the bubbles and calculate the bubble area. When writing the program, technicians will perform multiple levels of quantification and iteration on the grayscale value to reduce interference and determine weld seam bubbles.