Application of X-RAY Testing Equipment in Semiconductor Testing Field

Release time:2024-07-12Publisher:Jeenoce

In modern industrial production, X-RAY testing equipment plays an irreplaceable role in the field of semiconductor testing with its unique advantages. This technology utilizes the high permeability of X-rays to penetrate deep into the interior of semiconductors, revealing their subtle structures and potential defects, providing strong support for quality control in semiconductor manufacturing.

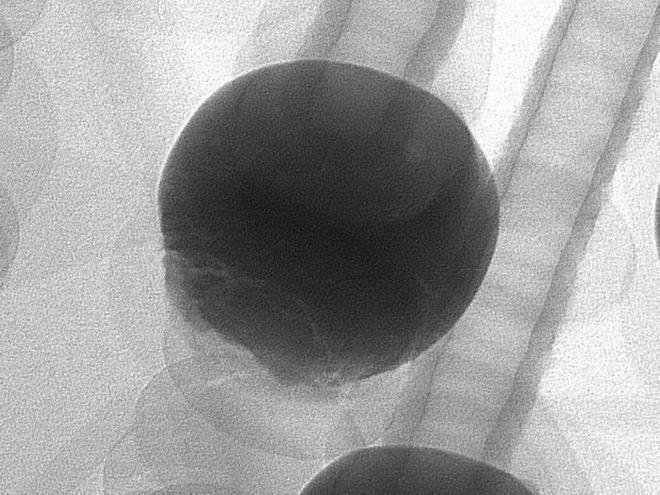

The basic principle of X-ray detection is that when electrons collide with a low-energy target material from a high energy level, X-rays are generated. These rays have short wavelengths and high energy, and can penetrate most substances, including semiconductor materials. When X-rays penetrate semiconductors, different materials will absorb and diffract them to varying degrees, forming unique images. These images can reveal the internal structure, defects, and material distribution of semiconductors.

In the semiconductor manufacturing process, X-RAY detection technology has a wide range of applications. It can not only be used to detect defects inside the package, such as welding defects, structural damage, missing, burrs or edges, but also to check the circuit connection inside the package to ensure the normal operation of the circuit. In addition, X-RAY detection can also be used to measure the thickness of packaging, helping to adjust the packaging process to achieve the best packaging effect. Compared with traditional semiconductor detection methods, X-RAY detection technology has significant advantages.

Firstly, it is a non-destructive testing method that does not require cutting or damaging the sample, thus avoiding damage to the sample. Secondly, X-RAY detection has the characteristic of high resolution, which can clearly reveal the subtle structures and defects inside the semiconductor. This makes it of significant application value in modern micrometer and nanometer sized semiconductor detection. Meanwhile, X-RAY detection technology also has the advantage of depth information. Compared with surface detection technology, it can provide information about the deep part of the sample, making it possible to detect defects inside the package or chip. The acquisition of such deep information is crucial for ensuring the overall quality and reliability of semiconductors. In the development of semiconductor X-ray detection equipment, technology is constantly innovating and advancing.

For example, some advanced equipment adopts CNC programs and array functions to achieve automatic batch detection of different positions of samples, greatly improving detection efficiency. In addition, these devices also have the function of one click measurement of bubble size, void ratio, length, width, etc., providing more detailed data support for detection. In terms of hardware, significant progress has also been made in semiconductor X-ray detection equipment. For example, some devices adopt automatic ON/OFF X-Ray tube technology, which can automatically turn on or off X-Ray tubes as needed, thus achieving batch testing of samples. This technology not only improves detection efficiency, but also reduces equipment energy consumption and maintenance costs. In addition to hardware and technological innovation, the user interface and visual navigation function of semiconductor X-RAY detection equipment have also been continuously optimized.