Reasons and solutions for low dispensing accuracy

Release time:2024-07-12Publisher:Jeenoce

In modern manufacturing, dispensing technology is widely used in fields such as electronic manufacturing, optoelectronic displays, semiconductor packaging, etc. Especially in the production process of micro parts, the role of dispensing machines is particularly important. However, the problem of low dispensing accuracy often troubles manufacturers, affecting product quality and production efficiency. This article will explore the main reasons for low dispensing accuracy and propose corresponding solutions.

1、 Glue dispensing machine equipment issues

Equipment aging or malfunction: With the increase of usage time, dispensing machine equipment may experience mechanical wear, pipeline blockage, or nozzle damage.

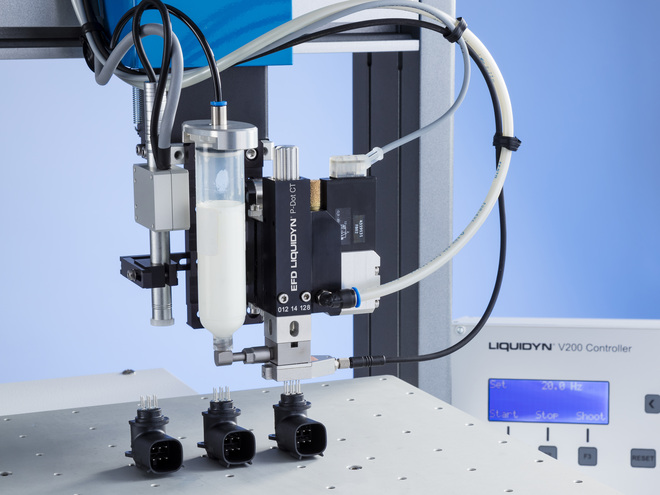

Insufficient equipment accuracy: The design and manufacturing process of low precision dispensing equipment may not be precise enough to meet the requirements of high-precision dispensing. For manufacturers of micro component dispensing machines, ensuring high precision of the equipment is the foundation for ensuring product quality.

resolvent:

Regular maintenance: Regularly inspect and maintain the dispensing machine, replace worn parts in a timely manner, clean pipelines and nozzles, and ensure that the equipment is in good condition.

Equipment upgrade: Choose high-precision and high stability dispensing equipment, especially in application scenarios that require high dispensing accuracy, automatic dispensing machines with precision control functions should be selected.

2、 Adhesive material issue

Adhesive characteristics: The viscosity, fluidity, and curing time of the adhesive directly affect the uniformity and stability of the dispensing process.

Glue quality: If there are impurities or bubbles in the glue, it will affect the dispensing accuracy.

resolvent:

Choose the appropriate adhesive: Choose the adhesive with the appropriate viscosity and flowability according to specific application requirements.

Glue treatment: Treat the glue before use, such as removing bubbles, filtering, etc., to avoid impurities affecting the dispensing effect.

3、 Process parameter setting issue

Glue dispensing pressure and speed: The setting of glue dispensing pressure and speed has a significant impact on the accuracy of glue dispensing. Excessive or insufficient pressure, as well as too fast or too slow speed, can all lead to poor dispensing quality.

Distance between nozzle and working surface: Improper distance between nozzle and working surface can lead to uneven distribution of glue or trailing phenomenon, thereby affecting the dispensing effect.

resolvent:

Adjust dispensing pressure and speed: Set dispensing pressure and speed reasonably to avoid excessive or insufficient deviation.

Adjust nozzle position: Reasonably adjust the distance between the nozzle and the working surface to ensure even distribution of glue.

Low dispensing accuracy is an important factor affecting product quality and production efficiency. By improving equipment maintenance, glue selection, and process parameter optimization, the dispensing accuracy can be effectively enhanced. In addition, with the development of automation and intelligent technology, the accuracy and stability of dispensing technology will be further improved, providing stronger support for precision manufacturing in various industries.