Key points for maintenance and repair of reflow soldering equipment

Release time:2024-07-12Publisher:Jeenoce

The key points of maintenance for reflow soldering equipment include the following aspects:

1. Cleaning: Regular cleaning of reflow soldering equipment is an important part of maintenance. It is necessary to disconnect the power supply of the equipment, wait for the equipment to cool down, and use a mild cleaning agent and soft cloth to clean the surface and interior of the equipment. Pay special attention to cleaning the welding area and conveyor belt to ensure that there are no residues in the welding area. At the same time, it is also necessary to maintain the cleanliness of electrical circuits.

2. Lubrication: The transmission components of reflow soldering equipment require regular lubrication to ensure normal operation and extend service life. Appropriate lubricants should be used to lubricate the transmission components according to the instructions in the equipment manual. Be careful to avoid excessive lubrication to avoid affecting the operation of the equipment. In addition, it is also necessary to lubricate the drive roller chain, such as coating it with high-temperature lubricating oil (molybdenum disulfide) every two months.

3. Hot air system maintenance: The hot air system of reflow soldering equipment is crucial for welding quality. Regularly check the hot air system, clean the hot air vents and fans to ensure that the hot air system is working properly. If any abnormalities are found, promptly repair or replace the key components of the hot air system.

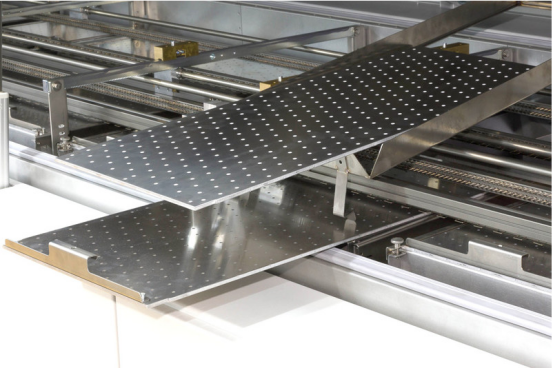

4. Conveyor belt maintenance: The conveyor belt of the reflow soldering equipment is a key component in the soldering process. The tension of the conveyor belt should be checked regularly to ensure smooth operation. At the same time, check the wear of the conveyor belt and replace the severely worn conveyor belt in a timely manner. When adjusting the tension of the conveyor belt, keep the tension rail clean and dust-free.

5. Temperature control system maintenance: The temperature control system of reflow soldering equipment plays an important role in welding quality. Temperature sensors and controllers should be regularly checked to ensure the accuracy and reliability of the temperature control system. If inaccurate temperature control is found, adjust or replace key components of the temperature control system in a timely manner.

6. Check welding quality: The maintenance of reflow soldering equipment also includes regular inspections of welding quality. By inspecting the appearance of the solder joints and the firmness of the welding connections, determine whether the welding quality meets the requirements. If poor welding quality is found, adjust equipment parameters or replace welding materials in a timely manner.

7. Daily maintenance: Daily maintenance includes tasks such as cleaning equipment, lubricating transmission components, and checking welding quality. It is recommended to perform daily maintenance to ensure the normal operation of the equipment and stable welding quality.

8. Regular maintenance: Regular maintenance includes tasks such as inspecting and maintaining the hot air system, conveyor belt, and temperature control system. It is recommended to conduct regular maintenance once a week to ensure the long-term stable operation of the equipment.

The above are the maintenance points for reflow soldering equipment. Proper maintenance and upkeep can ensure the normal operation of equipment, extend its service life, and improve welding quality.