The difference between through-hole reflow soldering and reflow soldering

Release time:2024-06-26Publisher:Jeenoce

Through-hole reflow soldering and reflow soldering are two different welding techniques, and their main differences are as follows:

1. Soldering object: Reflow soldering is mainly used for soldering surface mount components (SMD), which involves soldering components to the surface of a PCB board. And through-hole reflow soldering is used to solder through-hole insert components (THD), which means that the components are soldered to the middle or bottom layer of the PCB board.

2. Welding process: The reflow soldering process includes applying solder paste, mounting components, preheating, reflow soldering, and cooling. The process of through-hole reflow soldering includes applying solder paste, mounting components, preheating, reflow soldering, inserting components, and cooling.

3. Welding temperature: The welding temperature of reflow soldering is usually lower than that of through-hole reflow soldering. Because surface mount components are usually more sensitive than through-hole mount components, the temperature of reflow soldering needs to be controlled lower.

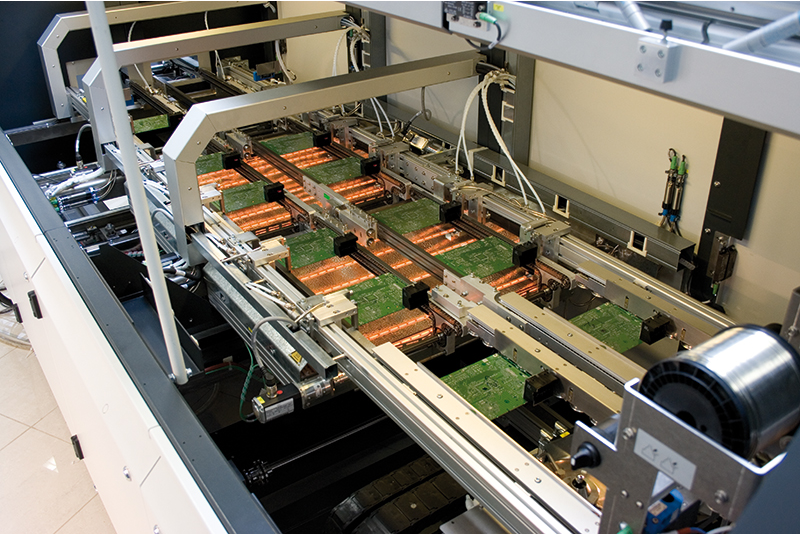

4. Welding equipment: The equipment used for reflow soldering and through-hole reflow soldering is different. Reflow soldering usually uses a reflow soldering furnace, while through hole reflow soldering requires a special through hole reflow soldering furnace.

5. Welding effect: Reflow soldering can achieve high welding quality and reliability, but it is not suitable for soldering through hole plug-in components. Through hole reflow soldering can solve this problem and achieve the soldering of through hole plug-in components, but it may require higher soldering temperatures and more complex process controls.

In summary, reflow soldering and through-hole reflow soldering are two different welding techniques that are suitable for different welding scenarios. In practical applications, it is necessary to choose appropriate welding techniques based on specific welding needs.