What are the advantages of using spray dispensing machines on small process components?

Release time:2024-06-27Publisher:Jeenoce

We know that any product is constantly updated and iterated, especially on some small process components, such as electronic components, industrial parts, automotive parts, etc. As users have higher requirements for product quality, manufacturers also have higher requirements for dispensing. However, traditional dispensing machines are difficult to meet the accuracy requirements of products, so people are focusing on spray dispensing machines. So, what are the advantages of spray dispensing machines in small process components? Let's take a look together with JEENOCE:

1. High accuracy

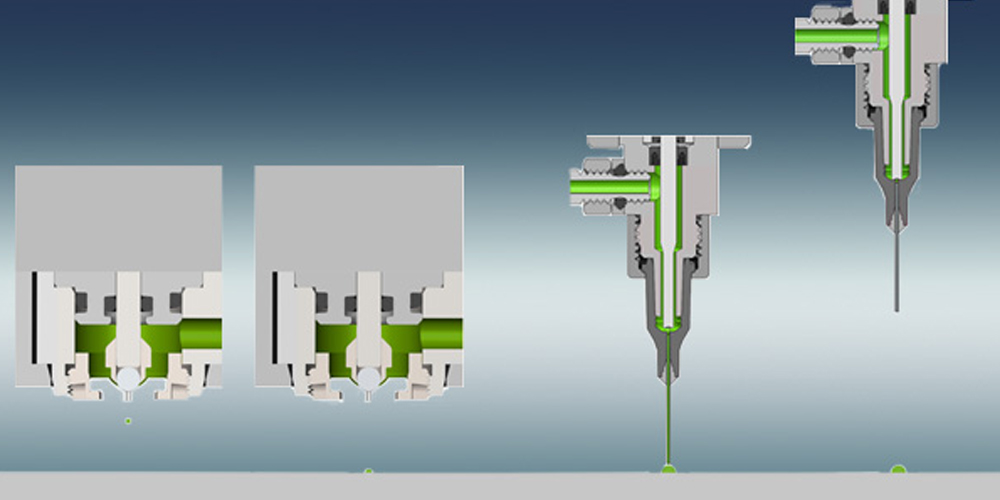

We know that traditional dispensing machines require customized fixtures, and the next step of dispensing work can only be completed by manually placing the product on the fixture, which has the characteristics of low efficiency and low accuracy. It can no longer meet the needs of today's customers for products, especially in small process components. Traditional dispensing machines are difficult to meet, while jet dispensing machines use imported jet dispensing valves, which not only have high accuracy, but also have non-contact dispensing function, so they are very capable of meeting the dispensing needs of small process components;

2. Can be paired with automatic systems and CCD vision systems for dispensing work

It is not difficult to find that compared with conventional dispensing machines, jet dispensing machines can automatically calibrate the distribution of low viscosity and medium viscosity fluids and slurries, achieving full automation in dispensing. At the same time, they are equipped with a CCD vision system for dispensing work, which can achieve three-dimensional and four-dimensional path dispensing, accurate positioning, accurate control of glue, no drawing, no leakage, and no dripping, which is very in line with process requirements.

3. Reduce enterprise operating costs

If the specifications of the dispensing are unreasonable, it will lead to product waste, serious waste of manpower and resources, which is a large operating cost for enterprises. The high accuracy of the spray dispensing machine, due to its high accuracy and intelligent settings, can also be connected to the network according to demand for remote control of robots, with strong load-bearing capacity and large processing space, reducing production costs for enterprises.