Common knowledge on the application of automatic dispensing machines

Release time:2024-04-18Publisher:Jeenoce

The large and medium-sized automatic dispensing machine with excellent high-speed dispensing characteristics has a three-dimensional effect on indoor space, and the programmable controller dispensing path passes through. The powerful automatic dispensing function is applied to carry out dispensing and painting work on products, and the actual effect of gluing on products is relatively good, ensuring no leakage and non-metallic wire drawing. However, before carrying out the gluing work on the products, it is important to note that these three key points in the gluing work can significantly and reasonably improve the actual gluing effect of the automatic gluing machine. Below is a detailed introduction to the application of automatic dispensing machines by JEENOCE.

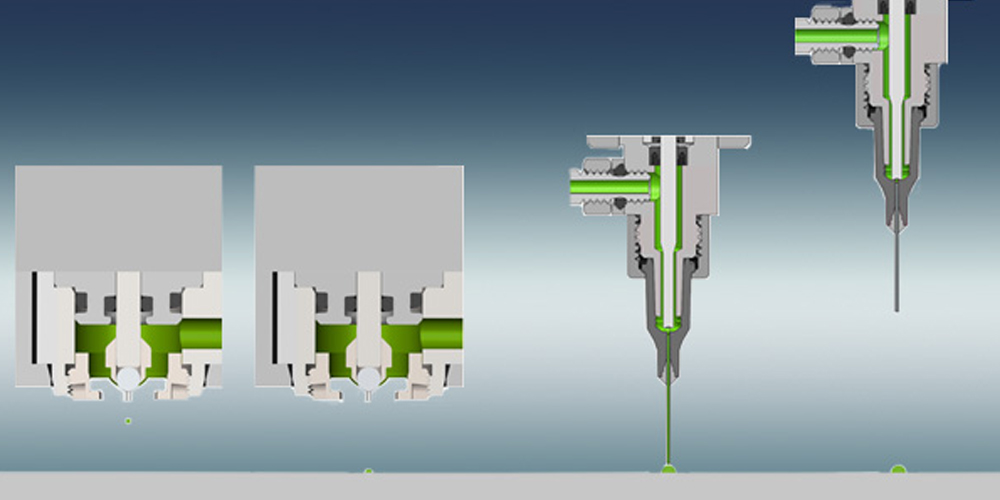

1. Pay attention to the selection of dispensing valves

The automatic dispensing machine is mainly used for dispensing and coating products, and this type of work mode can only be completed by coordinating the dispensing valves. Therefore, the selection of the type of dispensing valve is a crucial point. There are many types of dispensing valves that can be installed on automatic dispensing machines. In addition to opening the dispensing valve, installing a suction type dispensing valve can also improve the actual effectiveness of dispensing. The suction type dispensing valve has excellent actual glue suction effect. Installing a suction type dispensing valve in an automatic dispensing machine can effectively carry out the suction of glue, preventing problems such as dripping and overflow that may harm the actual glue application effect during operation.

2. Pay attention to the quality of the available glue

In addition to the appropriate selection of the suction type dispensing valve, which can improve the actual glue application effect of the automatic dispensing machine, the quality of the glue used can also harm the actual glue application effect. Therefore, before using the automatic dispensing machine to carry out store glue work on products, customers should first check the overall quality of the glue. If too much residue is added to the commonly used glue and it is good to replace it again, it can prevent the probability of glue problems.

3. Pay attention to the setting of the main parameters for dispensing

Before carrying out dispensing work on products, it is possible to set the dispensing route and main parameters during the work based on the specific requirements of the product store's glue and the hand-held teaching pendant. The automatic dispensing machine is equipped with a handheld teaching pendant. When setting the main parameters during operation, it is necessary to integrate the viscosity of commonly used glue and the requirements of the product for the mold closing force to adjust. In addition, the suction working pressure of the suction type dispensing valve should be adjusted to prevent the occurrence of glue metal drawing conditions that may harm the actual effect of the automatic dispensing machine's glue application.

In summary, when applying an automatic dispensing machine, attention should be paid to the selection of the dispensing valve, the quality of the available glue, and the setting of the main dispensing parameters.