Reflow welding machine heating system parameter indicators

Release time:2024-04-17Publisher:Jeenoce

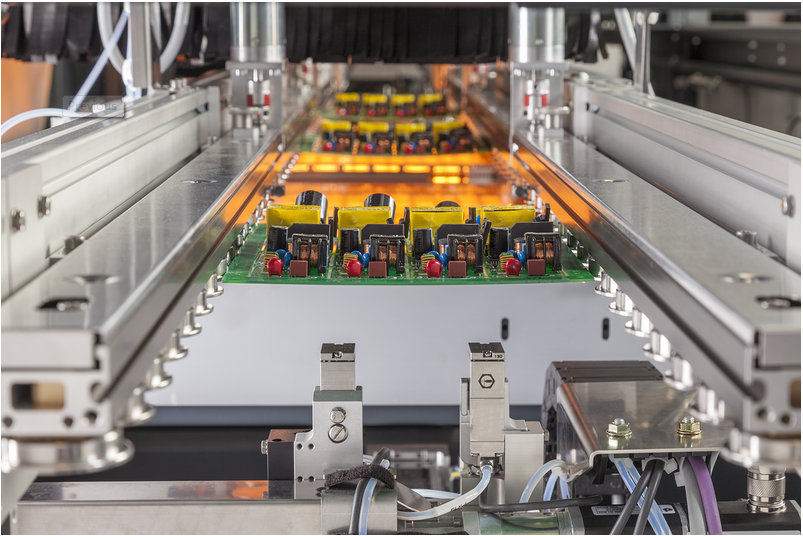

The heating system parameters of the reflow welding machine mainly include the number of heating temperature zones, temperature characteristic parameters, power consumption parameters, etc. JEENOCE would like to share in detail the parameters and specifications of the reflow welding machine heating system.

1、 Heating temperature range parameter indicators of reflow welding machine

Reflow welding machines should have at least three independent temperature controlled heating sections. The more heating sections there are, the more flexible the adjustment of process parameters. The number of heating sections is directly related to the heating length. The heating length is determined based on the specifications of the printed circuit board being soldered, the size of the equipment load factor, the high or low production efficiency, and the requirements of the product process. Generally, for medium and small batch production, 4-5 temperature zones are selected, and the length of the heating zone is about 1.8m to meet the requirements.

2、 Temperature characteristic parameter indicators of reflow welding machine

Temperature characteristics are a comprehensive reflection of the design quality of reflow welding machines, including four important indicators: temperature control accuracy, temperature non-uniformity, repeatability of temperature curves, and heating temperature.

1. The temperature control accuracy directly reflects the stability of the temperature field of the reflow soldering equipment, and its indicator range is mostly within ± 1 ℃~2 ℃, which requires sensitive temperature sensors.

2. Temperature non-uniformity, also known as the transverse temperature difference of the conveyor belt, is an important indicator of the performance of reflow soldering equipment. It refers to the temperature difference at any working position on a section perpendicular to the PCB conveying direction in the furnace. Generally, a bare PCB with a width of * * * can be soldered by a reflow soldering machine for testing, and is represented by the difference in peak welding temperatures at three test points. This indicator reflects the actual temperature on the printed circuit board and directly affects the welding quality of the product. The current advanced indicator is less than ± 2 ℃.

3. The repeatability of temperature curves directly affects the consistency of printed circuit board welding quality and should be highly valued. Generally speaking, this indicator should not exceed 2 ℃, which means that the temperature difference between different detection time periods at the same point should be measured multiple times.

4. The reflow welding machine should have a built-in temperature curve testing function.

5. Heating temperature: generally 300 ℃~350 ℃. If lead-free solder or metal substrate is considered, it should be above 350 ℃. The upper and lower heaters should have independent temperature control systems.

3、 Power consumption parameter indicators of reflow welding machine

The power of the reflow soldering machine is often overlooked when users choose it. In fact, for equipment manufacturers, the determination of power is determined through calculation, comparison, and even experimentation during design and development. In fact, the size of power not only affects the distribution load of users, but also has a great impact on the heating rate of equipment and the ability to quickly respond to changes in product load.

Due to different manufacturers having different load factor values for equipment products, usually ranging from 0.5 to 0.9, the heating time of the equipment generally does not exceed 30 minutes. Therefore, there are significant differences in the power of similar models, and attention should be paid when purchasing. Generally speaking, the heating time of the equipment should not exceed 30 minutes. During continuous operation of the equipment, the furnace temperature should be stable and its fluctuation should be less than ± 5 ℃.