Performance comparison and application scenarios of dispensing machines

Release time:2024-03-06Publisher:Jeenoce

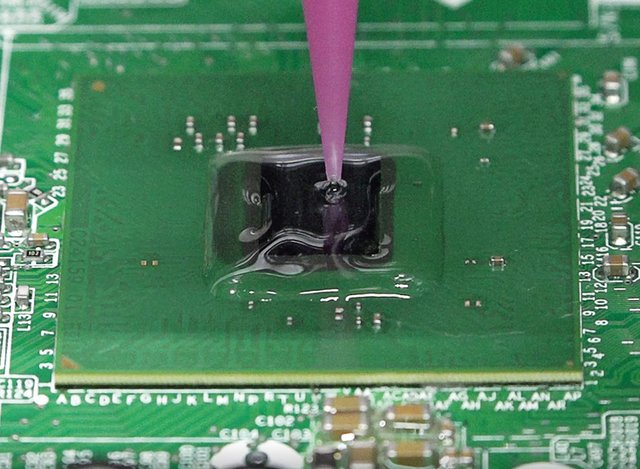

Glue dispensing machine, also known as glue dispensing machine, is a device used for automatic dispensing, widely used in industries such as electronics, optoelectronics, medical devices, and automobiles. The performance comparison of dispensing machines involves various factors, such as accuracy, speed, stability, control methods, etc. JEENOCE will provide a detailed introduction to the performance comparison and application scenarios of dispensing machines.

1、 Precision comparison is a very important indicator in the performance comparison of dispensing machines. Different application scenarios require different precision requirements for dispensing, so choosing a suitable dispensing machine is crucial. Generally speaking, high-precision dispensing machines use more advanced sensors and control systems to achieve more precise dispensing operations. Low precision dispensing machines are suitable for scenarios with relatively low requirements for dispensing accuracy, such as simple pasting or fixing operations.

2、 In addition to accuracy, speed is also an important indicator for comparing the performance of dispensing machines. Different applications require different dispensing speeds. Some high-speed production lines require dispensing machines with fast operating speed to improve production efficiency. In some scenarios that require precise operation, it is more important to ensure the accuracy of the dispensing process. Therefore, when choosing a dispensing machine, comprehensive consideration should be given based on specific application requirements.

3、 Stability is another key indicator of the dispensing machine. During long-term operation, the dispensing machine needs to have good stability to ensure consistency and stable quality of dispensing operations. Some high-end dispensing machines are equipped with advanced control systems and stability algorithms, which can maintain stable dispensing performance in different environments and working conditions.

4、 The control method of the dispensing machine is also one of the important factors in performance comparison. According to different application requirements, the dispensing machine can be controlled manually, semi-automatic, or fully automatic. The manual control method is suitable for some small batch scenarios that require manual operation. Semi automatic and fully automatic control methods are more suitable for large-scale and high-efficiency production lines. Choosing the appropriate control method based on specific application requirements can improve production efficiency and reduce costs.

The dispensing machine is widely used in industries such as electronics, optoelectronics, medical devices, and automobiles. The following are several common application scenarios:

Electronics industry: The dispensing machine is used for precise dispensing and soldering of electronic components during the electronic assembly process, ensuring reliability and stability.

Optoelectronics industry: In the manufacturing process of optical devices, dispensing machines can accurately apply glue and fix components, improving product quality and process stability.

Medical device industry: Gluing machines are widely used in the assembly and packaging process of medical devices, such as bonding wires, assembling sensors, etc.

The automotive industry: The dispensing machine has important applications in the manufacturing of automotive parts, such as the application of sealant and the fixation of car lights.

The performance comparison and application scenarios of dispensing machines cover aspects such as accuracy, speed, stability, and control methods. When selecting a suitable dispensing machine, it is necessary to consider the specific application requirements comprehensively. Whether in the electronics, optoelectronics, medical devices, or automotive industries, dispensing machines play an important role in improving production efficiency and product quality.