The difference between X-ray equipment inspection and manual visual and optical inspection

Release time:2024-03-06Publisher:Jeenoce

The quality of SMT patches is receiving increasing attention. From initial visual inspection (through human observation) to optical testing, every change in testing method is a technological advancement and a responsibility of enterprise management for product quality.

Manual visual inspection mainly involves observing the sample with the human eye to check its appearance, such as whether there is color deviation, whether there are scratches and stains on the surface, etc., mainly to detect the appearance;

Optical AOI appearance inspection is similar to visual inspection, mainly for appearance inspection;

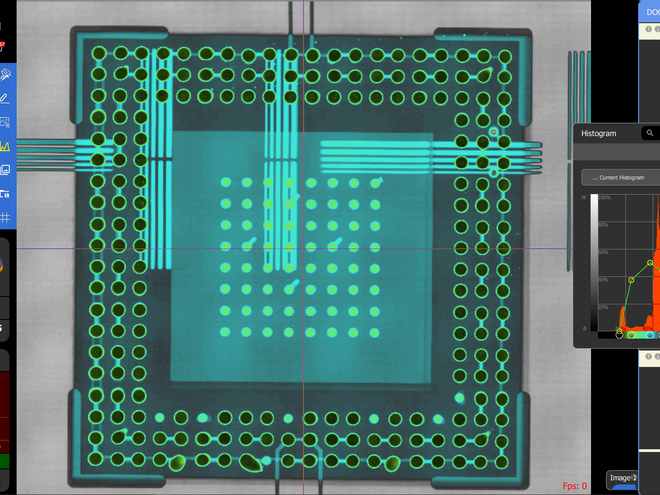

The X-ray detection equipment penetrates the sample through X-ray to detect the internal structure, defects, etc. of the sample;

The X-RAY device penetrates the interior of the sample and detects pattern patterns, which are very sensitive to false solder, missing solder, continuous solder on PCB boards, lithium battery welding, wire structure, etc. Currently, JEENOCE's X-RAY equipment mostly uses imported brand light tubes, which have stable performance and high resolution, and are widely used in various industries.