Methods for improving the quality of reflow soldering

Release time:2024-02-21Publisher:Jeenoce

The quality of circuit board reflow soldering directly affects the performance and quality of electrical products. JEENOCE shares several methods to improve reflow soldering quality:

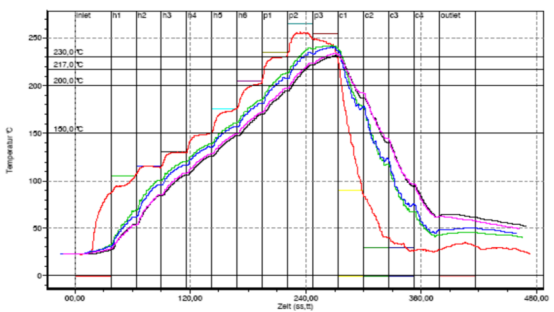

1. Control the temperature curve of the reflow soldering furnace. Using a standard temperature curve ensures that the product reaches sufficient welding temperature during reflow soldering, achieving good welding results while avoiding damage caused by excessive temperature.

2. Classify good and bad welding products and promptly eliminate welding defects. In the production process, quality inspection should be strengthened, welding defects should be detected in a timely manner and marked and classified to avoid defective products flowing into the next process.

3. Choose appropriate welding materials. Quality and durability should be emphasized in material selection according to actual needs to ensure the firmness and reliability of welding.

4. Strengthen maintenance and upkeep. The maintenance and upkeep of reflow soldering furnaces are crucial for ensuring welding quality. Maintain and clean the welding furnace according to requirements to ensure smooth passage and normal operation of heating tubes and other components.

5. Provide training to operators. Welding operators need to have certain professional knowledge and skills, be able to choose appropriate welding conditions based on the characteristics of the welded parts, timely detect and handle problems that occur during the welding process, and ensure welding quality.

In summary, the methods to improve the quality of reflow soldering need to start from multiple aspects and take various measures for comprehensive management and control to achieve the final welding quality assurance.