What are the advantages of industrial CT compared to other measuring instruments?

Release time:2024-02-21Publisher:Jeenoce

CT (Computed Tomography) may refer to CT technology in the medical field. In fact, the application of CT has already extended to the industrial measurement industry. With the transformation of industrial measurement from external traditional measurement to internal non-destructive analysis and full-scale measurement, industrial CT technology has emerged.

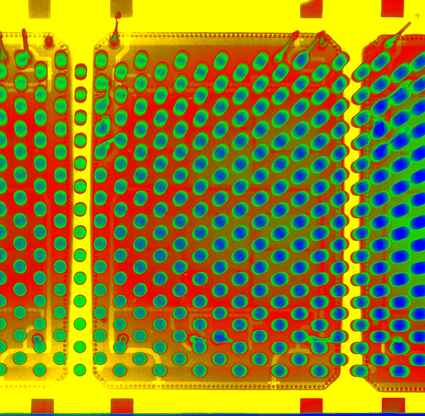

Industrial CT is a computer tomography imaging skill, which is a different imaging method from general X-ray imaging. General X-ray imaging involves projecting three-dimensional objects onto a two-dimensional plane for imaging, with each layer mirrored and stacked, causing mutual interference. This not only blurs the image but also loses depth information, which cannot meet the requirements of analysis and evaluation.

Industrial CT can be tested automatically: fast, simple, and convenient. The 380AC and 220AC power supplies automatically calculate the inflection point voltage, current, and composite error, and visually judge whether the transformer is qualified. It can automatically test and depict the volt ampere characteristic curve, eliminating tedious labor such as manual voltage regulation, manual recording, organization, and curve tracing; No need for specialized training, easy to master.

Industrial CT can qualitatively measure voltage transformers: during measurement, the instrument applies a certain power frequency voltage to the primary side of the voltage transformer to measure its primary voltage and secondary induced voltage, obtain the transformation ratio and polarity of the voltage transformer at this voltage, and conduct volt ampere characteristic experiments on the voltage transformer.

Industrial CT has multiple advantages compared to other measuring instruments such as CMM. Mainly as follows:

(1) Industrial CT can simultaneously measure the external and internal geometric shapes of objects without the need for disassembly or damage to the workpiece;

(2) Being able to achieve high point density in a short period of time;

(3) Non contact measurement.

However, there are many limitations in the application of industrial CT measurement technology in metrology, such as:

(1) There are numerous complex factors that affect tomography imaging;

(2) There is no complete and effective calibration standard yet;

(3) The measurement of industrial CT is usually untraceable, making it difficult to evaluate measurement uncertainty.