The role of temperature curve in reflow soldering

Release time:2024-01-30Publisher:Jeenoce

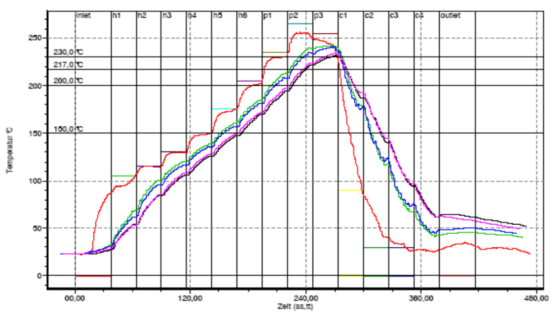

Reflow soldering is achieved by adjusting the temperature curve of the reflow soldering to achieve optimal reflow soldering results. The reflow soldering temperature curve intuitively reflects the temperature change process of the circuit board in the reflow soldering furnace. Welding without following the reflow soldering temperature curve can easily cause a large number of defective reflow soldering products.

The temperature curve of the reflow soldering furnace is generally set based on the solder paste you use, the components on the PCB, and the materials used. Moreover, the temperature curve produced varies in different PCBs and environments! The temperature curve we are testing is actually the temperature on the PCB board, not the temperature on the furnace you see. If the reflow soldering temperature curve is not set properly, all quality control measures in the previous stage will lose their significance. What is the temperature curve of reflow soldering? The process is quite complex and can be divided into two types: single-sided mounting and double-sided mounting. JEENOCE will explain it in detail for you:

From the temperature curve analysis, when the PCB enters the heating zone (drying zone), the solvents and gases in the solder paste evaporate, while the flux in the solder paste wets the solder pads, component terminals, and pins. The solder paste softens, collapses, and covers the solder pads, isolating them from oxygen gas; When the PCB enters the insulation area, sufficient preheating is provided for the PCB and components to prevent the PCB from suddenly entering the welding area and heating up too quickly, which may damage the PCB and components; When the PCB enters the soldering area, the temperature rapidly rises, causing the solder paste to reach a molten state. Liquid solder wets, diffuses, diffuses, or mixes with the solder pads, component terminals, and pins of the PCB to form solder joints; The PCB enters the cooling zone to solidify the solder joints and complete the entire reflow soldering.

The reflow soldering temperature curve is a chart that records the temperature changes of PCB printed circuit boards during the reflow soldering process. It can provide useful information to help engineers and technicians optimize PCB reflow soldering processes, ensuring quality and performance.