The key performance indicators of industrial CT systems include the following two types

Release time:2024-01-30Publisher:Jeenoce

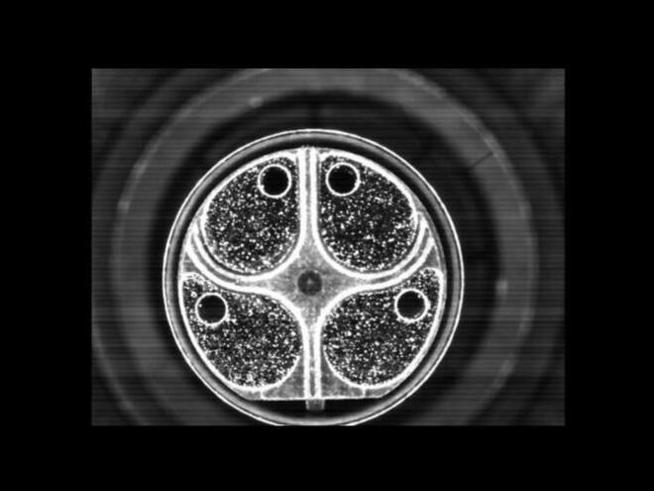

Industrial CT technology combines multiple technologies such as computer, automatic control, mechanical, optical physics, etc. It can ensure that the detected object obtains a cross-sectional image of the object without physical damage.

Industrial CT systems typically consist of radiation sources, mechanical scanning systems and automatic control systems, detector systems and data acquisition systems, computer systems, auxiliary systems, etc. The core principle is that the computer controls the radiation source to emit a beam of radiation, the CNC scanning platform carries the measured object and can move or rotate under computer control, and the flat panel detector is responsible for collecting scanning data; Shielding facilities ensure that radiation does not leak out and the scanning process is safe; Finally, the computer reconstructs industrial CT slice images from the collected projection data and classifies the defects present in the images.

Resolution is the core performance indicator of industrial CT systems, which includes two types: density resolution and spatial resolution.

1. Density resolution:

The ability to minimize density differences can be distinguished through CT images. (Generally evaluated based on the size of the feature area)

2. Spatial resolution:

The ability to identify minimal structural details can be identified through CT images.

The correlation between spatial resolution and density resolution. When the radiation dose is constant, the two indicators of spatial resolution and density resolution are contradictory. Increasing spatial resolution will lead to a decrease in density resolution, while increasing density resolution will lead to a decrease in spatial resolution.

Spatial resolution and density resolution are the core performance indicators of ordinary industrial CT systems, but for a high-precision measurement industrial CT system, it not only has the above two core performance indicators, but also has density measurement accuracy and geometric measurement accuracy.

In addition, the issue of testing costs that everyone is concerned about is that the testing fees for industrial CT are determined based on the material, size, and testing requirements of the tested products. Testing agencies that can directly provide quotations are basically basic testing. There are many application areas for industrial CT now, and the difficulty of testing has increased relatively. Non destructive testing is now popular in the industry to avoid the risk of product damage.