Analyze the working principle of the automatic dispensing machine

Release time:2024-01-23Publisher:Jeenoce

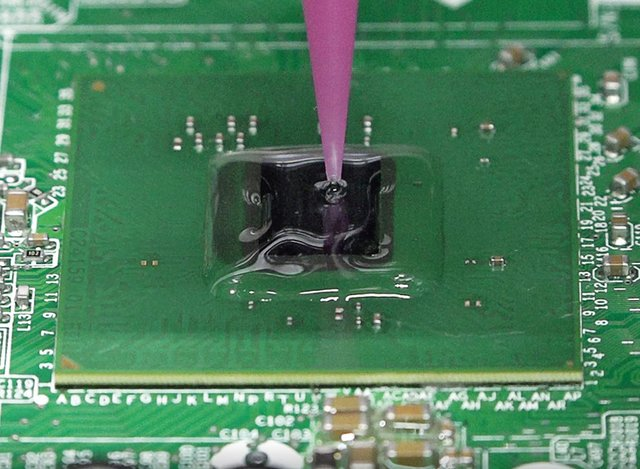

The task principle of the automatic dispensing machine is to feed compressed air into the glue bottle (syringe) and press the glue into the feed pipe connected to the piston chamber. When the piston is on the up stroke, the piston chamber is filled with glue. When the piston pushes the drip needle downwards, the glue is pressed out from the needle tip. The amount of glue dripping is determined by the interval between the downward flushing of the piston, which can be manually adjusted or controlled in software. Personality: High speed, low sensitivity to adhesive viscosity. The working principle of the dispensing machine is to send compressed air into the glue bottle (syringe), press the glue into the pipeline, and the glue flow is twisted at a certain speed through screws, ensuring a firm working time. The twisting of the screw creates a shear force on the adhesive, causing the adhesive to flow down along the rib pattern. The twisting of the screw continuously pressurizes the adhesive, causing it to flow out of the drip nozzle. Personality: It has the flexibility of adhesive point diameter without any firm limit, and can be stopped and adjusted through software. However, when gluing, the long twisting time of the screws will increase the rigidity output of the entire platform. In addition, the viscosity and activity characteristics of the adhesive can affect its stability.

The working principle of the non-contact drip glue pump dispensing machine is to send compressed air into the glue bottle (injector), press the glue into the feed pipe connected to the piston chamber, heat it here, control the temperature, and achieve a consistent viscosity. Apply the ball seat structure and use glue to fill the gap left by the ball retracting from the seat. When the ball returns, due to the force of deceleration, the glue flow is cut off, sprayed out from the glue needle, and droplets form glue dots on the board. Personality: Eliminating traditional methods of glue point tailing; There is no wear and tear of the dispensing needle and no interference with other complete machines; No needle damage; Not scrapped by the needle due to the substrate winding.