Reflow soldering temperature characteristics

Release time:2024-01-22Publisher:Jeenoce

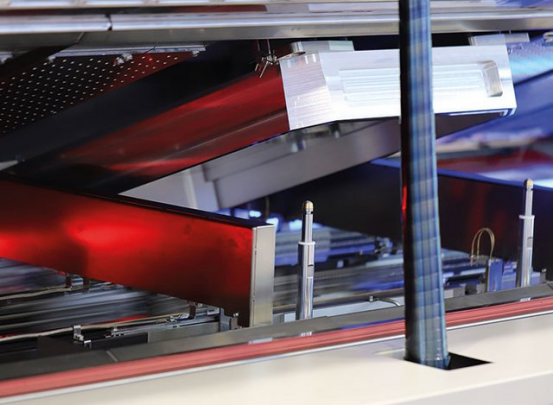

The main function of reflow soldering is to place the circuit board with mounted components into the track of the reflow soldering machine. Through heating, insulation, welding, cooling and other processes, the solder paste is transformed from a paste to a liquid through high temperature, and then cooled to a solid state, thereby achieving the function of soldering SMT electronic components to PCB boards. Temperature characteristics are a comprehensive reflection of the thermal design of reflow soldering equipment, including three important indicators: temperature control accuracy, temperature non-uniformity, and repeatability of temperature curves.

1. Temperature control accuracy

The temperature control accuracy directly reflects the stability of the reflow soldering equipment temperature. Currently, most indicators range from ± 1 ℃ to ± 2 ℃, meeting the requirements for reflow soldering.

2. Temperature non-uniformity

Temperature non-uniformity is an important indicator of the performance of reflow soldering equipment. It refers to the temperature difference at any working position on a section perpendicular to the PCB transfer direction in the furnace. Generally, reflow soldering machines can be used to solder bare PCBs for testing, and the difference in peak welding temperatures at three test points is used to represent it. As this indicator reflects the actual temperature on the printed circuit board and directly affects the welding quality of the product, the one with a smaller temperature difference is preferred. The current advanced indicator is less than ± 2 ° C.

3. Repeatability of temperature curve

The temperature curve refers to the curve of the temperature at the testing point on the surface mounted component over time, which is generally divided into four sections: preheating zone, pre reflux zone, reflux zone, and cooling zone. The repeatability of temperature curves directly affects the consistency of printed circuit board welding quality and should be highly valued. Generally speaking, during the heating process, this indicator should not exceed 4 ° C/S. 4-10 ℃/S is suitable during the cooling process.