Industrial CT: In depth understanding of 3D non-destructive testing technology

Release time:2024-01-22Publisher:Jeenoce

Industrial CT (X-ray computed tomography) is an advanced non-destructive detection technology that can obtain three-dimensional internal structural information of objects at high resolution by applying traditional CT scanning technology to the industrial field. This article will introduce the principle, application areas, and advantages of the device.

1. Principle:

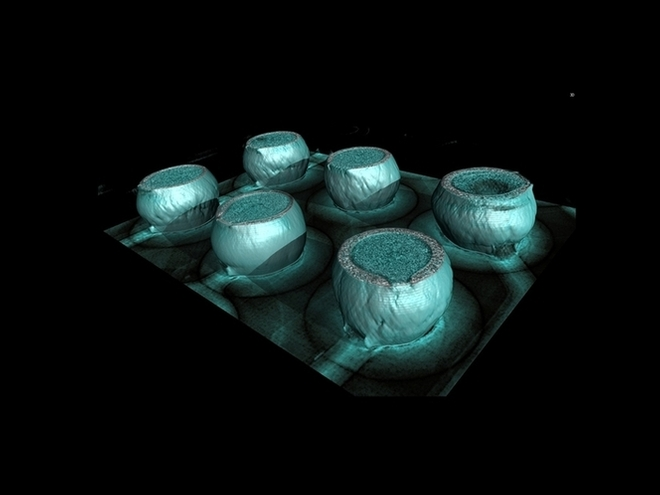

Industrial CT uses X-rays to penetrate objects and scan them at different angles. By collecting a large amount of cross-sectional image data and using reconstruction algorithms to generate high-resolution 3D models. These 3D models can provide information about the internal structure, defects, and assembly status of objects.

2. Application areas:

Industrial CT is widely used in many industries, including manufacturing, aerospace, automotive, electronics, medical devices, etc. It can be used for quality control, product design verification, defect detection, and fault analysis. For example, in the automotive manufacturing industry, this device can detect internal defects in engine parts, improving product quality and reliability.

3. Advantages:

This device has significant advantages over traditional detection methods. Firstly, it is a non-destructive technique that does not require destructive sampling of objects, avoiding damage and waste. Secondly, the device can provide high-resolution 3D images, revealing the small structures and defects inside objects, helping to accurately locate and quantitatively analyze problems. In addition, the device also has fast scanning speed and automated processing functions, greatly improving efficiency and productivity.

4. Implementation elements:

To implement this device, three key elements are mainly required: equipment, software, and professionals. The equipment includes components such as X-ray generators, detectors, and rotating platforms, and suitable equipment configurations need to be selected for different application fields. In terms of software, reconstruction algorithms and data analysis tools are crucial as they can reconstruct 3D models from cross-sectional image data and perform subsequent analysis. In addition, professionally trained operators and analysts are required to ensure the correct use and interpretation of results.

5. Development trend:

The technology of this device is constantly developing and growing. The future development trend includes higher resolution and faster scanning speed to meet the increasingly high testing requirements for complex components and products. In addition, the combination with other technologies such as machine learning and artificial intelligence will also provide more advanced defect detection and data analysis capabilities.

Industrial CT is an important three-dimensional non-destructive testing technology with a wide range of application areas and obvious advantages. It can provide high-resolution 3D images to help businesses improve product quality, reduce losses, and accelerate production processes. With the continuous advancement of technology, this device will play a more important role in the future, providing more reliable and efficient solutions for manufacturing and testing work in various industries.