Application of UV three proof paint coating in the circuit board industry

Release time:2024-01-22Publisher:Jeenoce

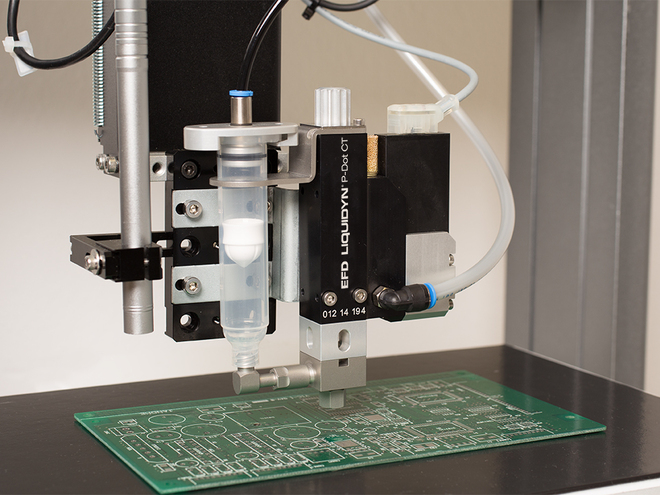

UV glue is widely used in circuit board coating. Through the coating machine, which is an automated machine, UV glue is atomized. According to the process characteristics, it can be selectively or whole board coated, and then cured in a furnace to achieve the three prevention effects. Below, we will introduce its characteristics to you.

Firstly: Environment/Safety

1. No VOC volatiles, no pollution to the ambient air; 2. There are relatively few restrictions or prohibitions on the composition of adhesives in environmental regulations; 3. Solvent-free, low flammability

Secondly, economy

1. The curing speed is fast, and it can be completed in a few seconds to tens of seconds, which is beneficial for automated production lines and improves labor productivity. 2. After curing, testing and transportation can be carried out, saving space. 3. Room temperature curing saves energy. For example, producing 1g of light cured pressure-sensitive adhesive only requires 1% of the corresponding water-based adhesive and 4% of solvent based adhesive. Can be used for materials that are not suitable for high-temperature curing. The energy consumption of UV curing can be reduced by 90% compared to thermosetting resins. 4. The curing equipment is simple, only requiring lamps or conveyor belts, saving space. 5. Single component system, no need for mixing, convenient to use

Finally: Compatibility

1. For temperature, solvent, and moisture sensitive materials, they can be used. 2. Control the curing process, adjust the waiting time, and adjust the degree of curing. 3. Can be repeatedly glued and cured multiple times. 4. UV lamps can be easily installed on existing production lines without significant changes. 5. High raw material cost, without low-cost solvents and fillers, 6. Adhesive prices are high. UV light has weak penetration into certain plastics or semi transparent materials, limited curing depth, and the geometric shape of curable products is limited. Non transparent parts and blind corners that cannot be exposed to UV light are not easy to cure. 7. General UV adhesive can only bond transparent materials, and other technologies such as light delay are needed to bond non transparent materials