Application Fields and Problem Solving Methods of Industrial CT

Release time:2024-01-23Publisher:Jeenoce

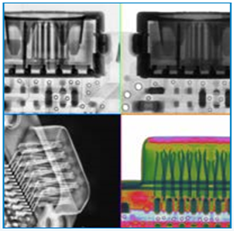

Industrial CT (Computed Tomography) is a three-dimensional non-destructive detection technology based on the principle of X-ray imaging. By rotating the tested object and performing multi angle X-ray scanning, high-resolution images of the internal structure of the object can be obtained. This product is widely used in multiple fields, such as automotive manufacturing, aerospace, electronic equipment, etc. However, during use, some common problems and malfunctions may also be encountered. JEENOCE will introduce the application areas of the product and provide corresponding problem-solving methods.

1、 Application field

1. Automotive industry: It can be used to detect engine components, welding quality, casting defects, etc., providing non-destructive testing methods that help with quality control and product improvement.

2. Aerospace: It can perform defect detection and accurate measurement on aircraft engine blades, composite material structures, and welded joints, improving safety and reliability.

3. Electronic equipment: can be used for 3D inspection of PCB boards, chips, connectors, etc., to help detect welding defects, component gaps, and other issues, improve product quality and reliability.

4. Plastic products: During the injection molding process, internal defects, bubbles, foreign objects, and other issues can be detected, which helps to improve the reliability and appearance quality of the product.

5. Casting and railway industry: It can conduct defect detection on large components such as castings and tracks, providing support for product traceability and quality improvement.

2、 Problem handling methods

1. Reconstruction image quality issue:

a. Check the scanning parameter settings, such as sampling rate, filtering algorithm, etc., and adjust them as needed.

b. Clean the detector and X-ray source to ensure the normal operation of the imaging system.

c. Calibrate CT equipment to ensure the accuracy of geometric and grayscale calibration.

2. The problem of long scanning time:

a. Adjust scanning parameters, such as rotation speed, angle interval, etc., to balance scanning speed and image quality.

b. Optimize data processing algorithms and image reconstruction methods to improve image reconstruction efficiency.

3. Poor imaging quality issues:

a. Check the placement and fixation of the tested object to ensure that the imaging area is aligned with the detector.

b. Adjust the voltage and current of the X-ray source, optimize imaging parameters to improve image quality.

c. Select appropriate filtering algorithms and reconstruction methods based on the characteristics of different materials and structures.

4. Security issues:

a. Strictly adhere to usage norms and operational requirements to ensure the safety of operators and surrounding personnel.

b. Regularly inspect the radiation protection measures of the equipment and repair any vulnerabilities or damages.

5. Equipment maintenance issues:

a. According to the recommendations of the equipment manufacturer, perform regular maintenance and upkeep, including cleaning detectors, calibration systems, etc.

b. Timely replace worn parts and accessories to prevent equipment failure and affect imaging quality.

Industrial CT is widely used in fields such as automotive manufacturing, aerospace, and electronic equipment, providing non-destructive and high-resolution 3D imaging technology. During use, common problems and malfunctions such as reconstructed image quality, long scanning time, and poor imaging quality may be encountered. By adjusting scanning parameters, optimizing data processing algorithms, and maintaining equipment, these problems can be solved to ensure the normal operation of the product equipment and the improvement of imaging quality.