Description of reflow soldering temperature curve

Release time:2024-01-09Publisher:Jeenoce

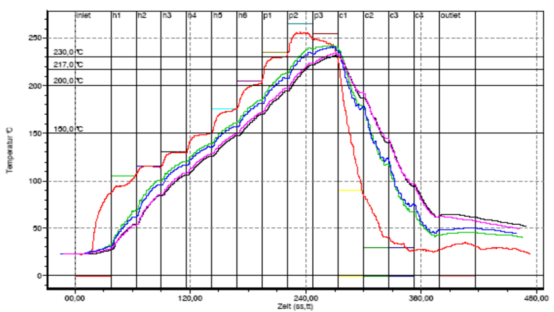

The reflow temperature curve of Surface Mount Technology (SMT) includes four parts: preheating, insulation, reflow, and cooling. Below, we will introduce the preheating and insulation sections.

(1) Preheating section

The purpose of this paragraph is to heat the circuit board at room temperature as soon as possible, but rapid heating cannot be fast enough to damage the board or parts and cause the loss of solvent in the flux. The usual heating rate is 1-3 ℃/second. In actual production, it is not necessary to require that the curves of each selected point reach a relatively ideal situation. Sometimes, due to differences in component density, high temperature tolerance, and significant differences in thermal characteristics, or due to differences in sheet metal and limitations in reflux furnace capacity, the temperature curves of some points cannot meet the requirements. In this case, it is necessary to comprehensively consider the impact of each component on the entire circuit board function and choose favorable reflux parameters.

(2) Insulation section

The boiling point of the solvent is between 125 and 150 ℃. Starting from the insulation section, the solvent will continue to evaporate, and the resin or rosin will begin to soften and flow at 70-100 ℃. Once melted, the resin or rosin can quickly diffuse on the welded surface. The active agent dissolved in it will flow and react with the surface oxide of the lead tin powder to ensure that the lead tin powder is clean during welding. The main purpose of the insulation section is to ensure that all components on the circuit board reach the same temperature before entering the welding section. The heat absorption capacity of components on the circuit board usually varies greatly, and sometimes the insulation period needs to be extended. However, too long insulation period may cause the loss of flux, which can be fully combined and wetted in the fusion welding area, weakening the solder ability of the solder paste. Too fast a temperature rise rate can lead to rapid solvent vaporization, It may cause defects such as blowing holes and solder beads, and a short insulation period may not allow the active agent to fully exert its effectiveness. It may also cause an imbalance in the preheating temperature of the entire circuit board, resulting in defects such as non tin sticking, post weld disconnection, and solder joint voids. Therefore, the length and temperature value of the insulation period should be determined based on the design of the circuit board and the convective heating capacity of the reflow furnace. The temperature of the general insulation section ranges from 100 to 160 ℃, with an increase rate of less than 2 degrees per second. A platform of about 0.5 to 1 minute around 150 ℃ helps to reduce the end area of the welding section to a smaller size.

(3) Reflux zone

The high temperature in the reflux zone is 245 degrees, the low temperature is 200 degrees, and the time to reach the value is approximately 35/S; The heating rate of the reflux zone is 45 degrees/35S=1.3 degrees/S. According to (how to correctly set the temperature curve), it can be seen that the time for this temperature curve to reach its value is too long. The entire reflux time is approximately 60 seconds

(4) Lingque District

The time for Lingque District is about 100 seconds, and the temperature drops from 245 degrees to around 45 degrees. The speed of Lingque District is: 245 degrees to 45 degrees=200 degrees/100S=2 degrees/S