Precautions for using AB glue in fully automatic glue filling machines

Release time:2024-01-10Publisher:Jeenoce

1、 What is AB glue

AB adhesive is a two-component adhesive. One liquid is the adhesive, and the other liquid is the hardener. Only when the two liquids are mixed can they harden. Common AB adhesives include AB epoxy resin, AB silicone, AB polyurethane, and PU adhesive.

2、 Packaging of AB adhesive

The packaging of AB glue can be in barrels or in tubes. Barrel packaging usually has a large quantity, with a capacity of 20KG per barrel, while support packaging is very small, around 1KG.

3、 Usage of AB adhesive

1. If manually pouring glue, first use a measuring cylinder to take AB glue in proportion, then pour it into a container for mixing and stirring. Be careful not to use too much each time, otherwise the glue will solidify and cause significant waste if not used up within the specified time.

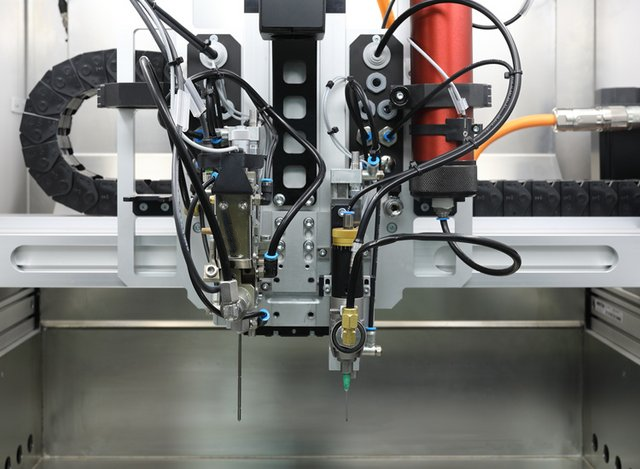

2. We use a fully automatic gluing machine for gluing, with automatic mixing, automatic gluing, quantitative dispensing, automatic routing, one click cleaning, saving time and effort. The machine automatically matches the amount used, which is much more efficient and high-quality than manual gluing.

4、 Precautions for using AB glue with fully automatic glue filling machine

1. The studio and equipment used must be kept clean, otherwise it will affect the quality and bonding effect of the adhesive, especially oil and dust, which can affect the transparency and adhesion of the adhesive. The indoor humidity should not be too high. Try to maintain ventilation or have exhaust fans. People should wear slippers or shoe covers when walking. When the indoor air is too cloudy, a small amount of water droplets can be sprinkled on the ground

2. The glue filling workshop should maintain a normal temperature of 25 degrees Celsius as much as possible. The temperature has a significant impact on the usable time and curing time of the glue. In addition, when turning on the air conditioning, pay attention to the fact that the water mist at the outlet directly sprays onto the surface of the glue layer, which reacts chemically with the B agent, causing phenomena such as white mist, oil stains, and granular particles

3. The glue filling workbench should be as stable as possible to avoid glue flow, exposure, inadequate dripping, and uneven dripping. A balance instrument or ruler can be used to adjust it first

4. Temperature has a significant impact on curing. As the temperature increases, the curing time accelerates. As the temperature decreases, the curing time prolongs. If the temperature is too high, it cannot be used and will damage the properties of the adhesive, making it impossible to restore to its original state. So it is necessary to choose between natural curing or oven heating for curing based on the properties of the adhesive.

5. The glue must be sealed and stored in a cool and ventilated place, avoiding high temperatures or sunlight. The yellowing is largely due to the glue not resisting UV rays in sunlight or exceeding a certain amount of exposure time

6. The glue must be strictly mixed according to weight ratio. If there is too much B agent, it will accelerate the curing and make the glue harder, even unable to dry; If the component of agent B is too small, the curing speed will slow down, making the adhesive softer and even unable to dry

7. If the product process requirements are strict, it is possible to consider loading a vacuum system to perform defoaming treatment on the adhesive.