What is the widespread application of industrial CT detection technology?

Release time:2024-01-09Publisher:Jeenoce

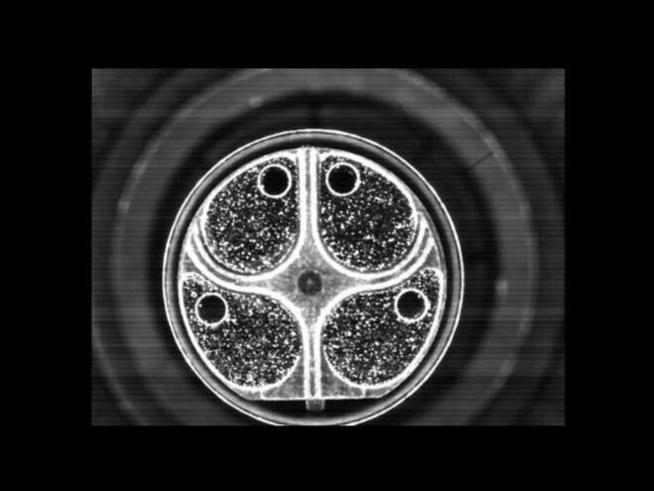

Industrial CT is computer tomography imaging technology, which is a completely different imaging method from general radiation imaging. General radiation imaging involves projecting three-dimensional objects onto a two-dimensional plane for imaging, with overlapping images at various levels causing mutual interference, resulting in blurred images and loss of depth information, which cannot meet the requirements of analysis and evaluation. CT is the process of isolating and imaging the detected fault of the object, avoiding interference and influence from other parts. It has high image quality and can clearly and accurately display the internal structural relationships, material composition, and defect conditions of the measured area. The detection effect is inferior to other traditional non-destructive testing methods.

The basic principle of industrial CT is based on the attenuation and absorption characteristics of radiation in the detected object. The ability of a substance to absorb radiation is related to its properties. So, using X-rays emitted by radioactive isotopes or other radiation sources with a certain energy and intensity, or γ The attenuation pattern and distribution of radiation in the detected object may be displayed by the detector to obtain detailed information about the interior of the object, and finally displayed in the form of an image using computer information processing and image reconstruction techniques.

CT technology was first applied in the medical field, forming Medical CT (MCT) technology, whose important role has been evaluated as a revolution in medical diagnosis. After the successful application of CT technology in the medical field, the United States was the first to introduce it to the aerospace and other industrial sectors, while other developed countries followed suit. After a short period of time, another branch of CT technology, Industrial Computed Tomography (ICT), was formed, and its important role was evaluated as a major technological breakthrough in the field of non-destructive testing.

CT technology (MCT and ICT) is widely used, and medical CT has become well-known to people. The application of industrial CT is almost ubiquitous in all industrial fields, making it more urgent for aerospace, aviation, military industry, and the military. China successfully developed its first practical industrial CT machine in 1993, and designed and produced the first commercial industrial CT machine mainly used for aerospace product inspection for the aerospace department in 1996. A series of products have been developed, and their application areas have rapidly expanded.

The characteristic of CT application in the aerospace industry is that it requires high safety and quality. Industrial X-ray machines and computed tomography (CT) systems can meet aerospace needs while also ensuring the safety and reliability of various aircraft components and materials.

Welding components in aerospace products have achieved high accuracy and reliability. Compared with ordinary radiographic testing methods, it has a unique effect and can detect defective parts more quickly.